-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Incoloy 800 Nickel Alloy Plate Sheet Alloy 800 Heat Resistant Nickel Base Plate From USA

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Nickel Alloy Sheet & Plate | Grade | Incoloy 800 |

|---|---|---|---|

| Thickness | 0.5 - 30.0mm | Standard Size | 1000*2000mm 1219*2438mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 NO.4 NO.8 |

| Highlight | Incoloy 800 Nickel Alloy Plate,Heat Resistant Nickel Alloy Plate,USA Nickel Alloy Plate |

||

Incoloy 800 Nickel Alloy Plate Sheet Alloy 800 Heat Resistant Nickel Base Plate From USA

| Products Name | Incoloy 800 Nickel Alloy Sheet Plate |

| Thickness | Cold rolled: 0.5 - 3.0mm Hot rolled 4.0 - 30.0mm |

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

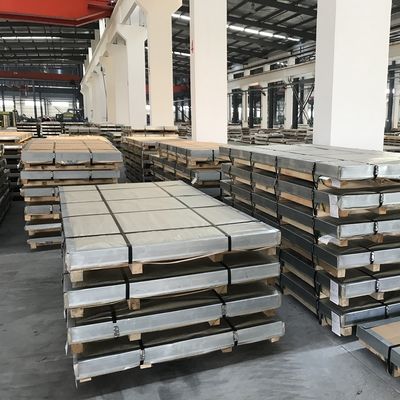

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Other Grade | Hastelloy C22 C4 X C276 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Incoloy 800 is a Nickel-Iron-Chromium super alloy that offers potential resistance to high temperature oxidation and carburization. It was further modified into Alloy 800H by lowering carbon content to 0.05 – 0.10 % which is further modified to 800HT by including titanium and aluminum to provide suitable high temperature characteristics.

Incoloy alloy 800 is highly resistant to chloride stress corrosion cracking and embrittlement. It has moderate high temperature strength and is certainly useful for petrochemical industry that includes long term operations up to 649oC or 1200oF.

Incoloy 800 covers ASME code up to 816oC, it offers superior oxidation resistance and is significant for service at the elevated temperatures in the non-ASME coded operations.

Industrial Nomenclatures: Ferrochronin® 800, Nickelvac® 800, Nicrofer® 3220, UNS N08800

Incoloy 800 Specification

| Wire | Sheet | Strip | Pipe | Fittings | Rod |

| AWS A5.11 ENiCrFe-2, AWS A5.14 ERNiCr-3, ASTM B408, AMS 5766, ISO 9723, | ASTM B409, AMS 5877, BS 3072NA15, BS 3073NA15, VdTüV 412 & 434, | DIN 17460, EN 10028-7, EN 10095 | ASTM B407, ASTM B829, ASTM B514, ASTM B775, ASTM B515, ASTM B751, BS3 3074NA15, ISO 6207, DIN 17459, VdTüV 412 & 434 | ASTM B366 | ISO 9724, BS 3076NA15, BS 3075NA15, EN 10095, VdTüV 412 & 434 |

Incoloy 800 Applications

Ethylene furnace quench boilers, hydrocarbon cracking, valves, fittings, industrial furnace components, heat processing apparatus, chemical and petrochemical processing units, pressure containers and tubes, heat exchanger parts and pipes, carburizing fixtures and retorts, Ammonia effluent cooler, superheater and reheater components in production units.

Incoloy 800 is used in the chemical plants for components of heat exchangers and transmission pipes of nitric acid solutions that need to prevent attack of chloride stress corrosion cracking. In the power production plants, the alloy is used in super-heater and re-heater tubes.

Incoloy 800 Processing

Forming: Alloy 800 is formable by the entire traditional forming methods due to its fine ductility. Use of strong tooling is recommended. Heavy duty lubricants are used while cold forming. It is important to fully remove the lubricant remainders subsequent to forming to prevent the risk of embrittlement.

Welding: Alloy 800 can be easily welded with common welding methods. Convex weld beads should be used. Remove oil, paint or crayon spots. Gas tungsten arc welding, gas metal arc welding and submerged arc welding are the commonly used joining methods for this super alloy.

Forms Produced

| Incoloy 800 Wire | Incoloy 800 Wire Mesh |

| Incoloy 800 Strip | Incoloy 800 Sheet |

| Incoloy 800 Rod | Incoloy 800 Pipe |

| Incoloy 800 Flanges | Incoloy 800 Foil |

Features of Incoloy Alloy 800

- High temperature strength.

- High creep rupture strength.

- Resistant to oxidation and carburization in high temperature environments.

- Good corrosion resistance in many acidic environments.

- Good resistance to many sulfur-containing atmospheres.

Incoloy Alloy 800 Applications

- Heat exchanger tubing for petrochemical processing.

- Valves and other piping components for sulfuric acid plants.

- Equipment for handling hydrogen chloride, acetic acid and sodium hydroxide.

- Flue gas desulfurization systems (scrubbers).

| Incoloy 800 Alloy Chemical Composition | |||||||

| % | Ni | Cr | Fe | C | Al | Ti | Al+Ti |

| Incoloy 800 | 30-35 | 19-23 | 39.5 min | 0.10 max | 0.15-0.60 | 0.15-0.60 | 0.30-1.20 |

| The mechanical properties of Incoloy 800 alloys are displayed in the following table: | ||

| Properties | Metric | Imperial |

| Tensile Strength(annealed) | 600 MPa | 87 ksi |

| Yield Strength(annealed) | 275 MPa | 39.9 ksi |

| Elongation | 45% | 45% |

| Incoloy 800 Alloy Standards Comparison Table | ||||||||

| ALLOY | USA | UNS | CHINA | EURONORM | RUSSIA | SWEDISH | JAPANESE | |

| GRADE | AISI/ASTM | NO | GB | NO | NAME | GOST | SS | JIS |

| INCOLOY 800 | 800 | N08800 | – | 1.4876 | – | – | – | – |

![]()

![]()

![]()

![]()

![]()