-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

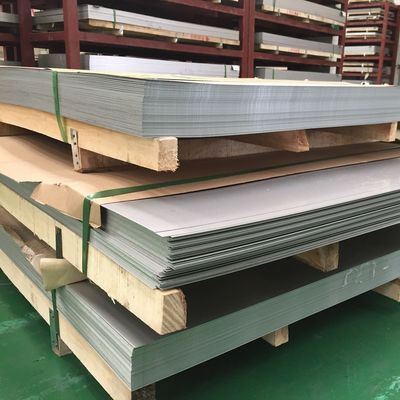

Inconel 718 Nickel Alloy Plate & Sheet Alloy 718 Cold Rolled Sheet 2B Surface With ASTM Standard

| Products | Nickel Alloy Sheet & Plate | Grade | Inconel 718 |

|---|---|---|---|

| Thickness | 0.5 - 30.0mm | Standard Size | 1000*2000mm 1219*2438mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 NO.4 NO.8 |

| Highlight | Inconel 718 Nickel Alloy Plate,Alloy 718 Nickel Alloy Plate,2B Surface Nickel Alloy Plate |

||

Inconel 718 Nickel Alloy Plate & Sheet Alloy 718 Cold Rolled Sheet 2B Surface With ASTM Standard

| Products Name | Inconel 718 Nickel Alloy Sheet Plate |

| Thickness | Cold rolled: 0.5 - 3.0mm Hot rolled 4.0 - 30.0mm |

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Other Grade | Hastelloy C22 C4 X C276 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Inconel 718 (Nickel 718) Strip, Coil, Foil, Wire, AMS 5596, AMS 5597, ASTM B670,

APPLICATIONS OF ALLOY INCONEL 718

- Honeycombs

- bellows

- seal rings

- fasteners

- spacers

DESCRIPTION OF INCONEL 718 MATERIALS

lnconel® 718 is a nickel-chromium alloy being precipitation hardenable and having high creep-rupture strength at high temperatures to about 1300 °F (700 °C). The poor age-hardening response of alloy 718 permits annealing and welding without spontaneous hardening during heating and cooling. This alloy has excellent weldability compared to the nickel-base super alloys hardened by Aluminum and Titanium.

CHEMISTRY TYPICAL OF INCONEL 718 MATERIALS

Nickel + Cobalt: 50.00 -55.00

Chromium: 17.00-21.00

Molybdenum: 2.80 -3.30

Columbium + Tantalum: 4.75 -5.50

Titanium: 0.65 -1.15 Aluminum: 0.20 -0.80

Cobalt: 1.00 max Carbon: 0.80 max

Manganese: 0.35 max Silicon: 0.35 max

Phosphorus: 0.015 max Sulfur: 0.015 max

Boron: 0.006 max Copper: 0.30 max

Iron: Balance

PHYSICAL PROPERTIES OF INCONEL 718

Density: 0.296 lbs/in3, 8.19 g/cm3

Specific Heat: Btu/lb ° F (J/kg ° C):

At 70 ° F (21 ° C): 0.104 (435)

Mean Coefficient of Thermal Expansion: in/in!° (mm/m/° C) 70 - 212 ° F (20 - 100 ° C): 7.6 x 10-5 (13.0)

Modulus of Elasticity: KSI (MPa)

29.7 x 103 (204.9 x 103) in tension

Magnetic Permeability, H = 200 Oersteds:

Annealed: 1.013

Annealed and Aged: 1.011

Melting Range: 2300 - 2437 ° F (1260 - 1336 ° C)

FORMS

Coil

- Strip

- Foil

- Ribbon

Wire

- Profile

- Round

- Flat

- Square

MECHANICAL PROPERTIES OF ALLOY 718 AT ROOM TEMPERATURE

ANNEALED TYPICAL

Ultimate Tensile Strength: 120 KSI min (827 MPa min)

Yield Strength: (0.2% offset) 60 KSI min (414 MPa min)

Elongation: 30% min (gauges:> 0.040 inches)

TEMPERED

lnconel® 718 can be cold rolled to various tempers. Contact Ulbrich Technical Service for additional information.

HEAT TREAT CAPABILITIES

Two heat treatments are generally utilized for lnconel® 718: Solution anneal at 1700 - 1850 ° F followed by rapid cooling, usually in water, plus precipitation hardening at 1325 ° F for 8 hours, furnace cool to 1150 ° F, hold at 1150 ° F for a total aging time of 18 hours, followed by air cooling. Solution anneal at 1900 - 1950 ° F followed by rapid cooling, usually in water, plus precipitation hardening at 1400 ° F for 10 hours, furnace cool to 1200 ° F, hold at 1200 ° F for a total aging time of 20 hours, followed by air cooling.

* Contact Ulbrich Technical Service for additional information.

ADDITIONAL PROPERTIES

INCONEL 718 CORROSION RESISTANCE

Refer to NACE (National Associate of Corrosion Engineers) for recommendations.

FINISHES

#1 - Hot rolled annealed and descaled. It is available in strip, foil and ribbon. It is used for applications where a smooth decorative finish is not required.

#2D - Dull finish produced by cold rolling, annealing and descaling. Used for deep drawn parts and those parts that need to retain lubricants in the forming process. #2B - Smooth finish produced by cold rolling, annealing and descaling. A light cold rolling pass is added after anneal with polished rolls giving it a brighter finish than 2D. #BA- Bright annealed cold rolled and bright annealed

#CBA- Course bright annealed cold rolled matte finish and bright anneal

#2 - Cold Rolled #2BA- Smooth finish produced by cold rolling and bright annealing. A light pass using highly polished rolls produces a glossy finish. A 2BA finish may be used for lightly formed applications where a glossy finish is desired in the formed part. Polished - Various grit finish for specific polish finished requirements.

* Not all finishes are available in all alloys - Contact Ulbrich Sales for more information.

WIRE FINISHES

XC - Extra Clean Bright Annealed or Bright Annealed and Cold Rolled Grease - Ultra bright finish (for decorative applications) Soap - Soap coating on tempered wire to act as lubricant. * Contact Wire Sales for custom wire finishes.

HEAT TREATMENT

lnconel® 718 can be hardened by: Cold Working Age Hardening Cold Working followed by Age Hardening