-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

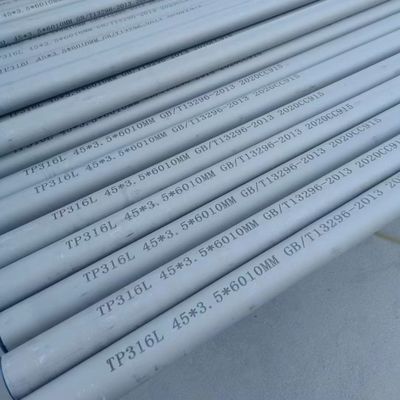

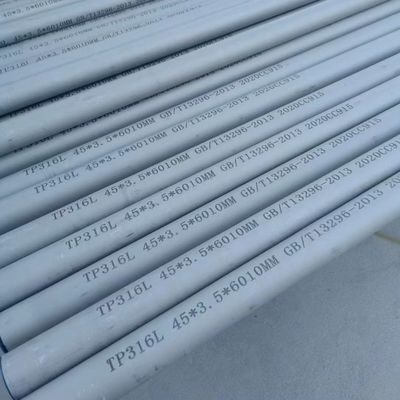

High Harden Stainless Steel Round Tube Forged Pipe Bright Polished SS 2205 SCH10

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 316L 321 310S 314 347 2205 2507 904 630 L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Welded Pipe | Grade | 304 316L 321 2205 310S 904L 17-4ph.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | Random Length Of 6m |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | Bright Stainless Steel Forged Tube Pipe,SCH10 Stainless Steel Forged Pipe,Stainless Steel 2205 Forged Pipe |

||

High Harden 17-4PH Stainless Steel Round Tube Forged Steel Pipe Bright Polished SS Pipe

| Name | stainless steel pipe |

| Standard | ASTM, GB, JIS, DIN, EN, AISI |

| Material Grade | TP304 TP304L TP316 TP316L TP347 TP347H TP321 TP321H TP310 TP310S |

| TP410 TP410S 17-4PH 254SMO 253MA | |

| S31803/S32205 S32750 S32760 | |

| Outer Diameter | Seamless Pipe: 4mm-812.80mm |

| Welded Pipe: single slit(Φ8mm-Φ630mm); girth(Φ630mm-Φ3000mm), | |

| Thickness | Seamless Pipe: 0.5mm - 60mm |

| Welded Pipe: single slit(0.5mm-25mm);girth(3mm-45mm) | |

| Length | 5.8-6.1 m or as customers' request |

| Tolerance | Acording to the Standard. |

| Surface | 180G, 320G, 400G Satin / Hairline |

| 400G, 500G, 600G or 800G Mirror finish | |

| Test | UT, ET, HT, RT,ect, and others according to the standard,or as the requests of the customers |

| Certificate | ISO9001-2008,ASME, PED |

| Delivery Time | 7-30 Days, Depends on quantity |

17-4 - UNS S17400:

Type 17-4 is the most common grade of martensitic precipitation hardenable (PH) alloys. 17-4 provides an outstanding combination of high strength, good mechanical properties at temperatures up to 600°F (316°C), and short-duration, low-temperature heat treatments that minimize warpage and scaling. Its good corrosion resistance, formability and weldability make it ideal for a variety of applications in aerospace, petrochemical, and other structural applications. In the annealed condition 17-4 maintains high mechanical properties making some forming operations difficult.

Physical Properties:

- Melting Point: 2560 - 2625°F (1404 – 1440°C)

- Density: 0.282 lbs/in3 / 7.8 g/cm3

- Modulus of Elasticity in Tension: 28.5 X 106 psi / 197 GPa

Mechanical Properties:

- Condition: Solution Treated (A)

- Tensile Strength Minimum (psi): 160,000

- Yield Strength Minimum 0.2% offset (psi): 145,000

- % Elongation in 2” Typical: 5%

- Hardness: Rockwell B85

- Condition: Hardened + Aged (TH1050)

- Tensile Strength Typical (psi): 200,000

- Yield Strength Typical 2% offset (psi): 185,000

- % Elongation in 2": 8%

- Hardness: Rockwell C35

- Condition: Aged (H1075)

- Tensile Strength Typical (psi): 175,000

- Yield Strength Typical 2% offset (psi): 165,000

- % Elongation in 2": 8%

- Hardness: Rockwell C37

- Condition: Aged (H900)

- Tensile Strength Typical (psi): 210,000

- Yield Strength Typical 2% offset (psi): 200,000

- % Elongation in 2": 7%

- Hardness: Rockwell C45

Composition of 630 Stainless Steel:

- Carbon: 0.07 max

- Manganese: 1.00 max

- Phosphorus: 0.040 max

- Sulfur: 0.030 max

- Silicon: 1.00 max

- Chromium: 15.00 - 17.50

- Nickel: 3.00 - 5.00

- Copper: 3.00 - 5.00

- Iron: Balance

Heat Treatments:

17-4 is typically supplied in Condition A, and can be heat treated at a variety of temperatures and times to achieve a wide range of properties. Below is a sampling of standard heat treatments for Condition A 17-4 material:

| Condition | Heat To (+/- 15°F / 8.4°C) | Time at Temperature (h) |

|---|---|---|

| H900 | 900°F / 482°C | 1 |

| H1025 | 1025°F / 551°C | 4 |

| H1075 | 1075°F / 580°C | 4 |

Corrosion Resistance:

Type 17-4 PH stainless steel withstands corrosive attack better than any of the standard hardenable (martensitic) stainless steels and is comparable to Type 304 in most media. The alloy exposed to seacoast atmosphere will gradually develop overall light rusting and pitting in all heat-treated conditions. In common with other stainless steels, 17-4 material is subject to crevice attack if exposed to stagnant seawater for any length of time.

FAQ

1. How can I get a quotation from you?

You can leave us a message, and we will reply to every message in time. Or we may talk online by Trademanager.

And you can also find our contact information on the contact page.

2.Can I get samples before order?

Yes, of course. Usually, our samples are free. we can produce your samples or technical drawings, all you need to pay is the shipping cost to you. We can build moulds and fixtures so we can customize our products based on your demand.

3. what is your delivery time?

It mainly depends on your location and demanded volume. The time of delivery is usually around 2 weeks.

We can send it out in 2 days if it has stock.

4.What is your payment terms?

Our usual payment term is 30% deposit and the rest against B/L. L/C is also acceptable. And the shipping terms are EXW, FOB, CFR, CIF and DDU. Whichever you like.

5. How can you guarantee the quality of my goods?

We are a factory with 100% pre-delivery inspection which guarantee the quality.

6 How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer and we sincerely do business with them, sustain our service level before and after every deal.

![]()

![]()

![]()

![]()