All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

EN 2.4819 Nickel Alloy Sheet Cold Rolled Hastelloy C276 For Chemical Industrial

Product Details

| Products | Nickel Alloy Sheet & Plate | Grade | Hastelloy C276 |

|---|---|---|---|

| Thickness | 0.6 - 3.0mm | Standard Size | 1000*2000mm 1219*2438mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 NO.4 NO.8 |

| Highlight | Nickel Alloy Sheet Cold Rolled,EN 2.4819 Nickel Sheet Alloy,Hastelloy C276 Nickel Sheet Alloy |

||

Product Description

EN 2.4819 Nickel Alloy Sheet Cold Rolled Hot Rolled Hastelloy C276 Alloy for Chemical Industrial

| Products Name | Hastelloy C276/ EN 2.4819 Sheet & Plate |

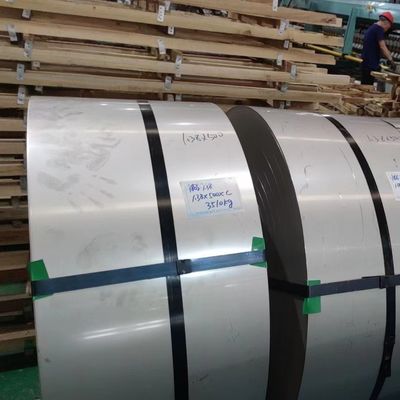

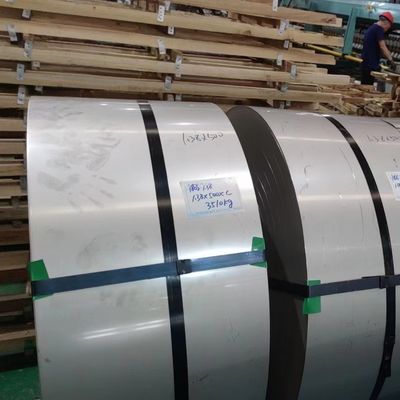

| Thickness | Cold rolled: 0.6 - 3.0mm Hot rolled 4.0 - 30.0mm |

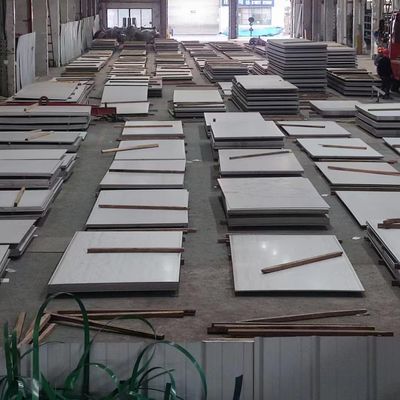

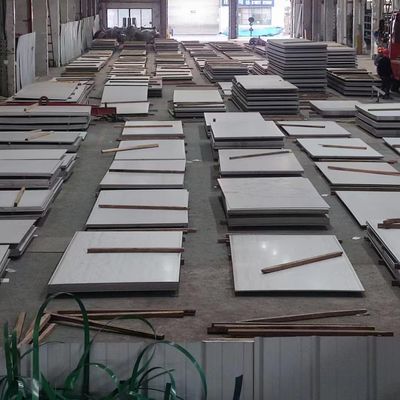

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Laser Cutting, Surface Finishing |

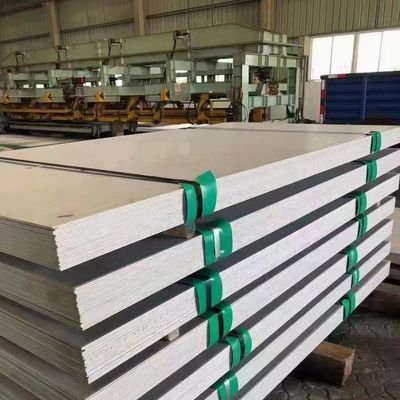

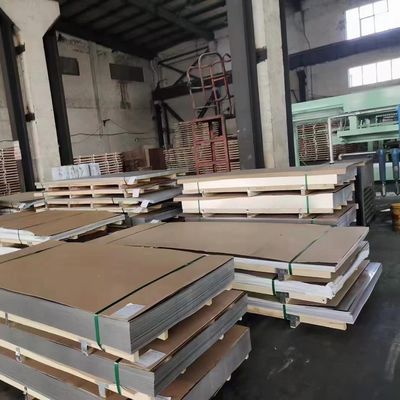

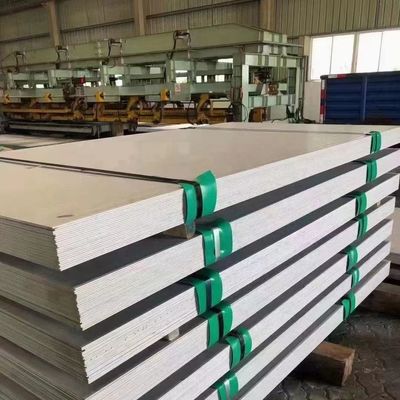

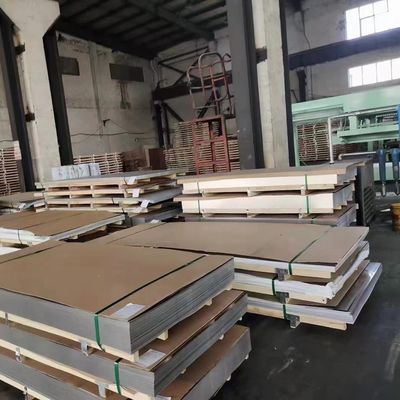

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Other Grade | Hastelloy C22 C4 X |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Grade Specification of EN 2.4819 / Hastelloy C276

| Material Designation | 2.4819 |

| Alloy | Alloy C276 |

| EN Material Symbol | NiMo16Cr15W |

| UNS | N 10276 |

| VdTÜV Data Sheet | 400 |

| DIN EN | DIN EN 17744 |

Application of alloy C276

AlloyC276 is often used in the chemical and petrochemical industries. The material is preferably used in cases where hot contaminated mineral acids, solutions and organic acids (such as acetic and formic acid) and seawater occur. Other areas of application include:

- - Sulfuric acid cooler

- - pulp and paper industry, for example for pulping and bleaching vessel

- - Equipment and components for Sour Gas

- - Washer and particular retrieval heater and fans for continuous wet combustion - flue gas and desulphurisation

- - Reactors for the production of acetic acid

- - Production and processing technology contaminated phosphoric acid

Chemical composition of alloy C276

| C | Si | Mn | P | S | Cr |

| % | ≤ % | ≤ % | ≤ % | ≤ % | % |

| 0.01 | 0.08 | 1.0 | 0.015 | 0.01 | 15.0-16.5 |

| Mo | Ni | Co | Fe | W | V |

| % | % | ≤ % | ≤ % | % | % |

| 15.0-17.0 | Rest | 2.5 | 4.0-7.0 | 3.0-4.5 | 0.1-0.3 |

Characteristics of alloy C276

| Temperature Range | Material for wet corrosion |

| Density | 8.9 g/cm³ |

| Melting Range | 1325 – 1370°C |

| Elongation at break of Alloy 59 at room temperature: | 30 % |

| ≤ 5mm | 25 % |

| ≥ 5 - ≤ 25 mm | |

| ISO-V notch impact toughness at -59°C | ≥ 120 J/cm² at room temperature |

| ≥ 90 J/cm² |

![]()

![]()

![]()

![]()

Recommended Products