-

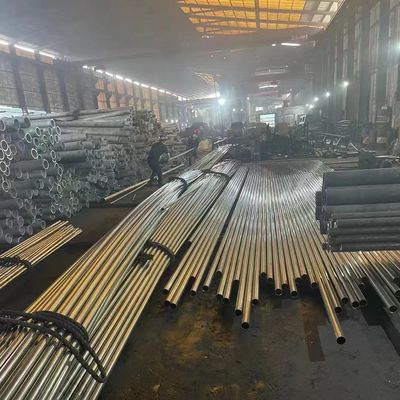

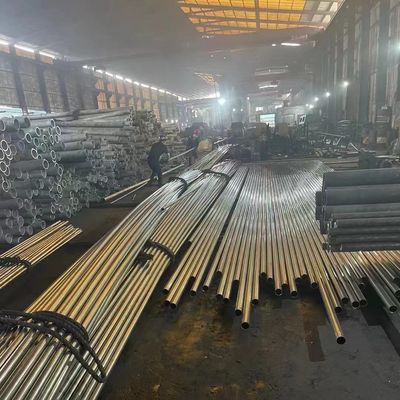

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

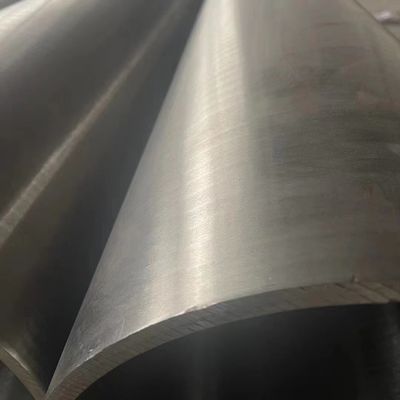

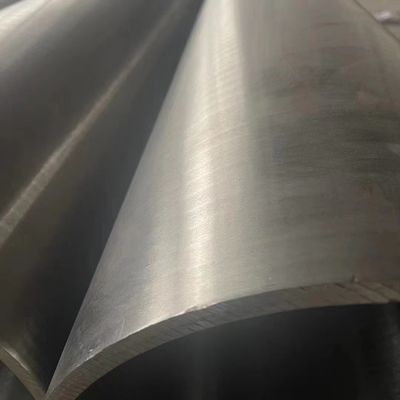

High Corrosion Resistant Stainless Steel Pipe 904L SS Tube 310S End Bevel Finishing

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Welded Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | Random Length Of 6m |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting |

| Other Shape | Square, Rectangle | ||

| Highlight | End Bevel Finishing Stainless Steel Pipe,Stainless Steel 310S Pipe Tube,DN400 Stainless Steel Tube Pipe |

||

High Corrosion Resistant Stainless Steel Pipe Grade 904L SS Pipe Tube End Bevel Finishing

| Product Name | Stainless steel pipe |

| Standard | ASTM AISI DIN,EN, GB JIS |

| Steel Grade | 200 Series: 201,202 300 Series: 301.304.304L,316,316L316Ti,317L.321.309s,310s 400 Series: 409L410,410s,420j1,420j2,430,444,441,436 Duplex Steel: 904L 2205,2507,21012520,2304 |

| Outer Diameter | 6-600mm(as required) |

| Thickness | 0.3mm-40mm (as required) |

| Length | 2000mm/2500mm/3000mm/6000mm/12000mm(as required) |

| Technique | Welded,Seamless |

| Surface | pickling / polished |

| Tolerance | 土1% |

| Price Terms | FOB.CFR.CIF |

UNS NO8904, commonly known as 904L, is a low carbon high alloy austenitic stainless steel which is widely used in applications where the corrosion properties of AISI 316L and AISI 317L are not adequate.

The addition of copper to this grade gives it corrosion resistant properties superior to the conventional chrome nickel stainless steels, in particular to sulphuric, phosphoric and acetic acids. However, there is limited use with hydrochloric acids. It also has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. Alloy 904L performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum.

The grade is non-magnetic in all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures.

The high chromium content promotes and maintains a passive film which protects the material in many corrosive environments.904L has a greater resistance to precipitation of ferrite and sigma phases on cooling and welding than other stainless steels containing molybdenum such as 316L and 317L. There is no risk of intercrystalline corrosion on cooling or welding due to the low carbon content. Its maximum service temperature is at 450°C.

This grade is particularly useful in control and instrumentation tubing applications where 316 and 317L are not suitable.

Available tube product forms

- Weled Pipe

- Seamless Pipe

- Coil Pipe

Typical Applications of 904L Stainless Steel Pipe

- Seawater cooling equipment

- Chemical processing for sulphuric, phosphoric and acetic acids

- Gas washing

- Condenser tubes

- Control and instrumentation

- Heat exchangers

Typical manufacturing specifications of 904L Stainless Steel Pipe

- ASTM A213

- ASTM A269

- ASTM A312

- BS EN 10216 pt.5

- Also individual customer specifications.

Industries predominantly using this grade

- Chemical processing

- Oil and gas

- Pharmaceutical

Technical Data

Mechanical Properties

| Temper | Annealed | |

|---|---|---|

| Tensile Rm | 71 | ksi (min) |

| Tensile Rm | 490 | MPa (min) |

| R.p. 0.2% Yield | 32 | ksi (min) |

| R.p. 0.2% Yield | 220 | MPa (min) |

| Elongation (2” or 4D gl) | 35 | % (min) |

Physical Properties (Room Temperature)

| Specific Heat (0-100°C) | 450 | J.kg-1.°K-1 |

| Thermal Conductivity | 11.5 | W.m -1.°K-1 |

| Thermal Expansion | 15.8 | μm/μm/°C |

| Modulus Elasticity | 190 | GPa |

| Electrical Resistivity | 9.52 | μohm/cm |

| Density | 7.95 | g/cm3 |

Chemical Composition (% by weight)

| Element | Min | Max |

|---|---|---|

| C | - | 0.02 |

| Mn | - | 2 |

| Ni | 23 | 28 |

| Cr | 19 | 23 |

| S | - | 0.3 |

| Mo | 4 | 5 |

| N | - | 0.1 |

| Cu | 1 | 2 |

| P | - | 0.03 |

| Si | - | 0.7 |

![]()

![]()

![]()

![]()