-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

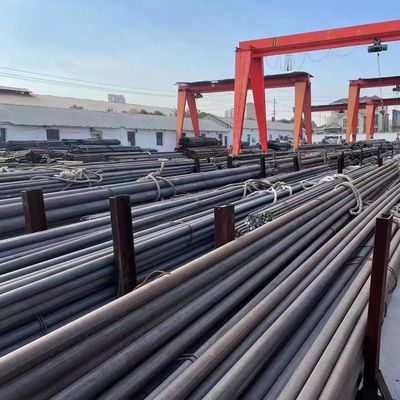

SA276 316Ti Stainless Steel Round Bar Diameter 5 - 350mm Custom Cutting any Length

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 316Ti 321 309S 310S 2205 17-4PH XM-19 |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Shape | Round | Standard | ASTM EN GB JIS |

|---|---|---|---|

| Grade | 201 304 316L 316Ti 309S 310S 321 329 2205 2507.etc | Application | Construction,Industry,surgical Tools,seawater Equipment.,kitchenware |

| Length | Customers' Requirements,5.8m,6m,2m-6m,or As Required | Size | Custom As Request |

| Packing | Standard Seaworthy Package,In Wooden Cases(for FCL/ LCL Shipment) | Service | Cutting, Surface Finishing |

| Highlight | stainless steel round bar,stainless steel bar stock,steel round bar |

||

SA276 316Ti Stainless Steel Round Bar Diameter 5 - 350mm Custom Cutting any Length

| Products | Stainless Steel Bar |

| Grade | 316Ti |

| Diameter | 5 - 350mm |

| Length | 6m or custom cutting any length as request |

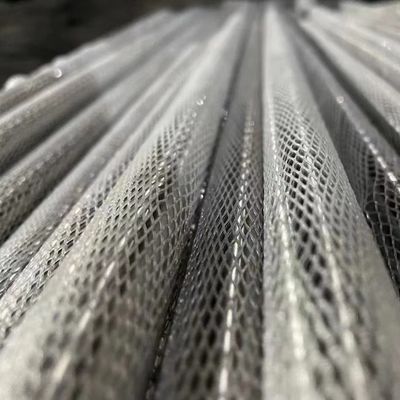

| Finishing | Bright Bar / Black Surface |

| Heat Treatment | Solid Solution , ageing |

| Surface Process | Polishing , Peeling |

| Other Grade |

201 303 304 304L 309S 310S 316L 316Ti 317L 321 347 410 420 430 431 2205 2507 904L 254SMO 416 440A/B/C.etc |

| MOQ | 500 Kgs |

| Loading Port | Shanghai Port |

| Processing | Cutting |

| Packing | Wooden box or cutting as request |

This data sheet applies to stainless steel 316Ti / 1.4571 hot and cold rolled sheet and strip, semi-finished products, bars and rods, wire and sections as well as for seamless and welded tubes for pressure purposes.

Application

Construction encasement, doors, windows and armatures, off-shore modules, container and tubes for chemical tankers, warehouse and land transportation of chemicals, food and beverages, pharmacy, synthetic fibre, paper and textile plants and pressure vessels. Due to the Ti-alloy, resistance to intergranular corrosion is guaranteed after welding.

Chemical Compositions of 316Ti Stainless Steel

| Element | % Present (in product form) | |||

|---|---|---|---|---|

| C, H, P | L | TW | TS | |

| Carbon (C) | 0.08 | 0.08 | 0.08 | 0.08 |

| Silicon (Si) | 1.00 | 1.00 | 1.00 | 1.00 |

| Manganese (Mn) | 2.00 | 2.00 | 2.00 | 2.00 |

| Phosphorous (P) | 0.045 | 0.045 | 0.0453) | 0.040 |

| Sulfur (S) | 0.0151) | 0.0301) | 0.0153) | 0.0151) |

| Chromium (Cr) | 16.50 - 18.50 | 16.50 - 18.50 | 16.50 - 18.50 | 16.50 - 18.50 |

| Nickel (Ni) | 10.50 - 13.50 | 10.50 - 13.502) | 10.50 - 13.50 | 10.50 - 13.502) |

| Molybdenum (Mo) | 2.00 - 2.50 | 2.00 - 2.50 | 2.00 - 2.50 | 2.00 - 2.50 |

| Titanium (Ti) | 5xC to 070 | 5xC to 070 | 5xC to 070 | 5xC to 070 |

| Iron (Fe) | Balance | Balance | Balance | Balance |

Mechanical properties of 316Ti Stainless Steel

| Product Form | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | P | L | L | TW | TS | |||

| Thickness (mm) Max | 8 | 12 | 75 | 160 | 2502) | 60 | 60 | ||

| Yield Strength | Rp0.2 N/mm2 | 2403) | 2203) | 2203) | 2004) | 2005) | 1906) | 1906) | |

| Rp1.0 N/mm2 | 2703) | 2603) | 2603) | 2354) | 2355) | 2256) | 2256) | ||

| Tensile Strength | Rm N/mm2 | 540 - 6903) | 540 - 6903) | 520 - 6703) | 500 - 7004) | 500 - 7005) | 490 - 6906) | 490 - 6906) | |

| Elongation min. in % | A1) %min (longitudinal) | - | - | - | 40 | - | 35 | 35 | |

| A1) %min (transverse) | 40 | 40 | 40 | - | 30 | 30 | 30 | ||

| Impact Energy (ISO-V) ≥ 10mm thick | Jmin (longitudinal) | - | 90 | 90 | 100 | - | 100 | 100 | |

| Jmin (transverse) | - | 60 | 60 | 0 | 60 | 60 | 60 | ||

Reference data on some physical properties

| Density at 20°C kg/m3 | 8.0 | |

|---|---|---|

| Modulus of Elasticity kN/mm2 at | 20°C | 200 |

| 200°C | 186 | |

| 400°C | 172 | |

| 500°C | 165 | |

| Thermal Conductivity W/m K at 20°C | 15 | |

| Specific Thermal Capacity at 20°C J/kg K | 500 | |

| Electrical Resistivity at 20°C Ω mm2 /m | 0.75 | |

Processing / Welding

Standard welding processes for this steel grade are:

- TIG-Welding

- MAG-Welding Solid Wire

- Arc Welding (E)

- Laser Beam Welding

- Submerged Arc Welding (SAW)