-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

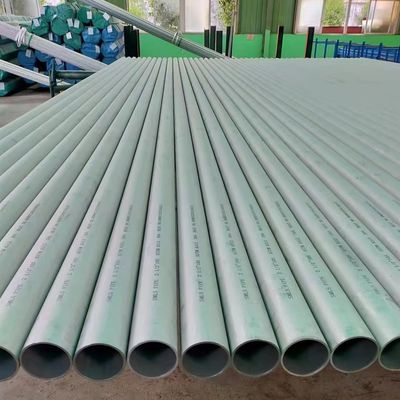

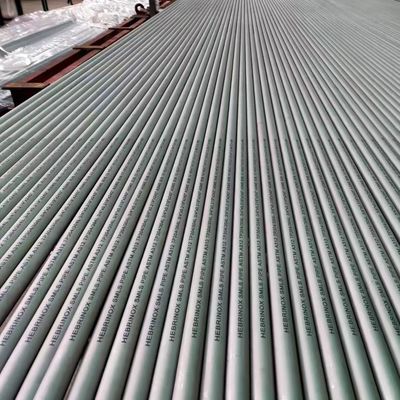

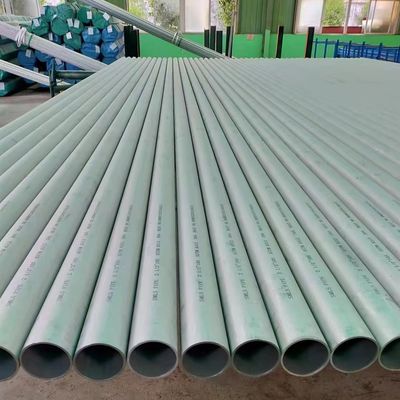

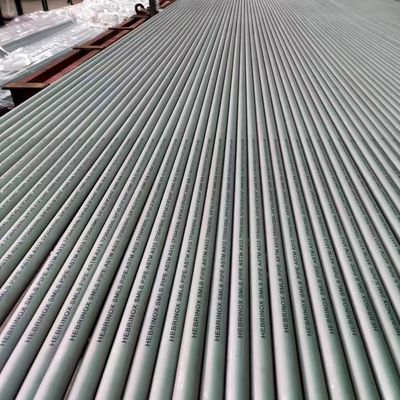

Super Duplex 2507 / S32750 Stainless Steel Pipe ASTM A790 SS OD10 - 219mm

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 316L 321 310S 314 2205 2507 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 2507 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | Random Length Of 6m |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting |

| Highlight | Super Duplex ASTM Stainless Steel Pipe,S32750 Stainless Steel Pipe,219mm Stainless Steel Pipe |

||

Super Duplex 2507 / S32750 Stainless Steel Pipe ASTM A790 SS Pipe OD10 - 219mm

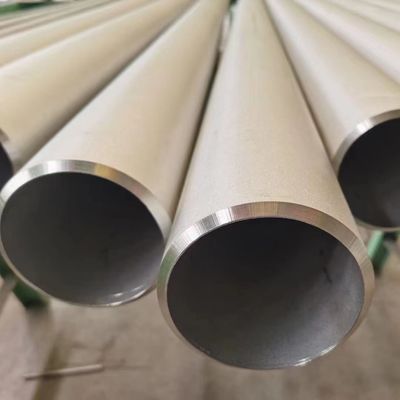

Super duplex pipes produced under specification ASTM A790, are supplied in a seamless or a welded construction. The automatic process used to manufacture Super Duplex Welded Pipe is without the use of a filler metal. The Super Duplex Pipe suppliers recommend using these pipes for applications that are prone to general corrosion resistance. There are several reasons that account for the corrosion resistance properties of the ASTM A790 UNS S32760 pipe. In addition to having a high content of molybdenum, nickel and chromium, there is a significant inclusion of austenite stabilizing element, nitrogen. A heat analysis is performed on the ASTM A790 UNS S32750 in order to determine the proportion of the elements specified herein.

Next, the mixed microstructure of the Super Duplex 2507 Pipe enhances its properties. For instance, the ferritic part of the duplex microstructure in the alloy of the pipe is responsible for the Super Duplex 2507 Seamless Pipe exhibiting superior resistance to stress related corrosion cracking, particularly when exposed to warm chloride ion bearing circumstances. Generally, tests such as flattening tests, hardening tests, hydrostatic tests, Tension tests and nondestructive electric tests are performed on the Super Duplex Seamless Pipe to ascertain their conformance to the ASTM A790.

Manufacturer of Alloy 2507 Stainless Steel Pipe in grade ASTM A790 UNS S32760 and ASME SA 790 UNS S32750

Super Duplex 2507 Pipe sizes

Looking for Super Duplex Pipe suppliers? Buy 2507 Seamless Pipe in exact length to save cost and wastage

Super Duplex Seamless Pipe

- Size: 4 - 219mm

- Thickness : 0.5 - 20mm

- Length: Single, Double Random & Cut Length

Super Duplex Welded Pipe

- Size: 5.0 - 1219.2 mm

- Thickness : 0.5 - 20mm

- Length: Single, Double Random & Cut Length

2507 Duplex Stainless Steel Seamless Pipe Specification

|

ASTM A790 PIPE |

SIZE |

RATING |

ASTM SPECIFICATION |

|---|---|---|---|

| 2507 Welded Pipe | 6"-12" | 10s, 40s | ASTM 790 |

| 2507 Seamless Pipe | ½"-8" | 10s, 40s, 80s, 160 | ASTM 790 |

| Super Duplex 2507 Pipe International Specification | ASTM A 789 ASME SA 789 |

| Standard Specification | ASME, ASTM, AISI, AMS, JIS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB |

| Super Duplex Seamless Pipe Size |

|

| 2507 Duplex Stainless Steel Welded Pipe Size |

|

| Super Duplex 2507 EFW Pipe Size |

|

| Super Duplex Stainless Steel Pipe WT | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| 25cr Super Duplex 2507 Pipe manufacturing techniques | Seamless / ERW / EFW/ Welded / Fabricated / CDW/ LSAW/ Seam-Welded / Redrawn |

| Origin of Duplex 2507 Stainless Steel pipe material | Indian, European, Korean, Japanese |

| 2507 Duplex SS Pipe End Types |

|

| Form | Round, Square, Rectangular |

| Super Duplex Alloy 2507 Pipe Length | Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded |

| 2507 Super Duplex Stainless Steel Pipe Delivery Condition | Annealed and Pickled, Hot Finished, Polished, Bright Annealed, Cold Drawn |

| Super Duplex Grade 2507 Pipe Packing |

|

| Duplex Steel 2507 Pipe Value Added Services | Cut to size, thread, and groove |

| Port | Mumbai, India |

| Stocking distributor of leading Super Duplex 2507 Pipe manufacturers |

|

| Duplex Steel 2507 Pipe Dimensional Specification | ANSI/ ASME B36.10, B36.19, B2.1 |

| Marking on Super Duplex 2507 Pipe |

|

Super Duplex 2507 Pipe Inspection & Test reports

- Mill Test Certificates with all Super Duplex 2507 Pipe

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Third Party Inspection for Super Duplex Pipe

- Mechanical Reports

- Chemical Reports

- PMI Test Reports

- Visual Inspection Reports

- Destructive Test Report

- NABL Approved Lab Reports

- Raw Materials Certificate

- Non Destructive Test Reports

- 100% Radiography Test Report

- Fumigation Certificates

- HS Code Commercial Invoice

- Heat Treatment Charts

- Surface roughness measurement

- Form A for Generalized System of Preferences (GSP)

- Laboratory Test Certificate from Govt. Approved Lab

- Moisture testing

Super Duplex 2507 Seamless Pipe Chemical Composition

| GRADE | SUPER DUPLEX 2507 |

|---|---|

| Carbon (C) Max. | 0.030 |

| Manganese (Mn) Max. | 1.20 |

| Phosphorous (P) Max. | 0.035 |

| Sulphur (S) Max. | 0.020 |

| Silicon (Si) Max. | 0.80 |

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 6.0–8.0 |

| Molybdenum (Mo) | 3.0–5.0 |

| Nitrogen (N) | 0.24–0.32 |

| Iron (Fe) | Bal. |

| Copper (Cu) | 0.50 |

| Other Elements | - |

![]()

![]()

![]()

![]()