-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

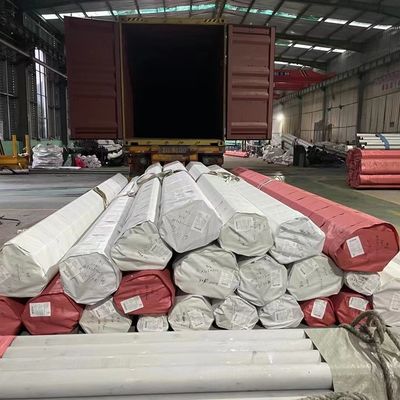

ASTM A312 TP321 Stainless Steel Pipe Heat Resistant SS For Gas OD10 - 406mm

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 316L 321 310S 314 2205 904L.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Pipe | Grade | 304 316L 321 2205 310S 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | Random Length Of 6m |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting |

| Highlight | TP321 Stainless Steel Pipe,seamless Stainless Steel Pipe Heat Resistant,OD406mm Stainless Steel Pipe |

||

ASTM A312 TP321 Stainless Steel Pipe Heat Resistant SS Pipe for Gas Pipe OD10 - 406mm

| Products | TP321 Stainless Steel Pipe |

| Type | Seamless Pipe |

| Grade | 304 304L 309S 310S 316L 321 317L 316Ti 2205 2507 904L |

| Out Diameter | OD10 - 406mm |

| Length | 6m or custom cutting any length as request |

| Thickness | SCH10 SCH40 SCH80 SCH160 or unstandard size |

| Loading Port | Shanghai Port |

| MOQ | 500 kgs |

| Packing | standard Packing suit for export |

321 Stainless Steel Tubing

Another variant of the 304 standards, small diameter 321 stainless steel tubing (UNS designation UNS S32100) composition includes titanium which makes the resulting tubing stronger and more corrosion resistant at higher temperatures.

Small diameter 321 stainless steel tubing has substantially better resistance to intergranular corrosion which is corrosion that occurs in between the microstructure---between the grains of different elements that make up the alloy. 321 SS is, therefore, an important material option for tubing products with service cycles in the 800-1500º carbide precipitation range because the life of the product will be extended (relative to other grades of stainless steel).

321 SS Tubing Features & Applications

321 stainless steel tubing manufactured for high-temperature applications exhibits excellent resistance to fatigue and cracking, making it ideal for applications including:

- Metal O-ring products

- Select aerospace applications

- Exhaust manifolds

- Oil and gas/refinery applications

- Processing equipment for high-temperature chemicals

- Many other high-temperature service applications

Like our other welded and drawn products, small diameter 321 SS tubing is welded from strip stock, plug drawn in coil form, annealed as needed in order to meet customer temper requirements, and offered in straight lengths or coil form.

Type 321 is a standard austenitic 18/8 chromium nickel alloy with the addition of Titanium making it an excellent choice in elevated temperature environments.

The titanium stabilises the material removing its susceptibility to the effects of intergranular corrosion. 321 is therefore the stainless steel material of choice for applications in working environments up to 9000 C.

A drawback of Type 321 is that the titanium does not transfer well across a high temperature arc, so it is not recommended as a welding consumable.

In such instances, 347 is the preferred choice as the Niobium performs the same function as Titanium but can be still transferred across a high temperature arc. Type 347 is therefore the consumable of choice for welding Grade 321.

The steel has excellent forming and welding qualities and excellent toughness even at cryogenic temperatures. If you are looking for a stainless steel to provide resistance to intergranular corrosion, 304L is the normal choice as it is a more commonly used and supplied steel.

However, 321 is a much better option in operating temperature environments in excess of 5000 C and therefore have its own merits.

Note that Type 321 does not polish well so it is not practical to use this material as cosmetic architectural feature.

Stainless Steel DIN 1.4541 / 1.4878 Seamless TubesStockist, SS UNS S32100 / S32109 Seamless Tubing, SS 321 Cold Drawn Tubes, SS 321H Seamless Tubes, SS 321 Seamless Tubing In India.

Production, Supply, Stock Range of Stainless Steel 321, 321H Pipes and Stainless Steel 321H Tubes

- Outside Diameter:6.00 mm OD up to 250 mm OD, Sizes up to 12” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

- Thickness Range:0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

- Type: Seamless / ERW / Welded / Fabricated / CDW

- Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U” Shape, Pan Cake Coils, Hydraulic Tubes

- Length: Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded

- End Protection: Plastic Caps | Outside Finish: 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

- Delivery Condition: Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

- Inspection, Test Reports: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

- Packing: Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

- Specials: Sizes and Specifications other than above can be manufactured on request

Composition of 321 Stainless Steel Pipes

Typical compositional ranges for grade 321 stainless steels are given in table 1.

Table 1. Composition ranges for 321 grade stainless steel

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Other | |

| 321 | min. max |

- 0.08 |

2.00 | 0.75 | 0.045 | 0.030 | 17.0 19.0 |

- | 9.0 12.0 |

0.10 | Ti=5(C+N) 0.70 |

| 321H | min. max |

0.04 0.10 |

2.00 | 0.75 | 0.045 | 0.030 | 17.0 19.0 |

- | 9.0 12.0 |

- | Ti=4(C+N) 0.70 |

| 347 | min. max |

0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 17.0 19.0 |

- | 9.0 13.0 |

- | Nb=10(C+N) 1.0 |

Mechanical Properties of 321 Stainless Steel Pipes

Typical mechanical properties for grade 321 stainless steels are given in table 2.

Table 2. Mechanical properties of 321 grade stainless steel

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 321 | 515 | 205 | 40 | 95 | 217 |

| 321H | 515 | 205 | 40 | 95 | 217 |

| 347 | 515 | 205 | 40 | 92 | 201 |

| 321H also has a requirement for a grain size of ASTM No 7 or coarser. | |||||

![]()

![]()

![]()

![]()