-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Alloy 329 Stainless Steel Bar Custom Cutting UNS S32900 From BAOSTEEL SS Rod

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 309S 310S 2205 17-4PH XM-19 |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Shape | Round | Standard | ASTM EN GB JIS |

|---|---|---|---|

| Grade | 201 304 316L 309S 310S 321 329 2205 2507.etc | Application | Construction,Industry,surgical Tools,seawater Equipment.,kitchenware |

| Length | Customers' Requirements,5.8m,6m,2m-6m,or As Required | Size | Custom As Request |

| Packing | Standard Seaworthy Package,In Wooden Cases(for FCL/ LCL Shipment) | Service | Cutting, Surface Finishing |

| Highlight | BAOSTEEL Stainless Steel Bar Rod,UNS S32900 Stainless Steel Bar,Alloy 329 Stainless Steel Bar |

||

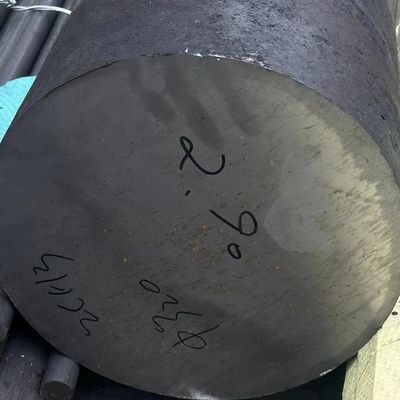

Alloy 329 Stainless Steel Bar Custom Cutting SS Bar UNS S32900 from BAOSTEEL SS Rod

| Products | Stainless Steel Bar |

| Grade | 329 / UNS S32900 / 1.4460 |

| Diameter | 4 - 350mm |

| Length | 6m or custom cutting any length as request |

| Finishing | Bright Bar / Black Surface |

| Heat Treatment | Solid Solution , ageing |

| Surface Process | Polishing , Peeling |

| Other Grade |

201 303 304 304L 309S 310S 316L 316Ti 317L 321 347 410 420 430 431 2205 2507 904L 254SMO 416 440A/B/C.etc |

| MOQ | 500 Kgs |

| Loading Port | Shanghai Port |

| Processing | Cutting |

| Packing | Wooden box or cutting as request |

329 Stainless Steel Composition

UNS S32900 is an austenitic stainless steel alloy with a combination of iron, chromium, nickel, molybdenum, and nitrogen. This combination makes it highly resistant to corrosive elements like salt water or chlorine in marine environments and other industrial chemicals. It also has great resistance to pitting and crevice corrosion owing to its high chromium content. Furthermore, it has a higher carbon content compared to other grades of stainless steel, which gives it greater strength when exposed to heat treatment processes.

| Element | Content (%) |

|---|---|

| Iron, Fe | 63 |

| Chromium, Cr | 28 |

| Nickel, Ni | 4.5 |

| Manganese, Mn | 2 |

| Molybdenum, Mo | 1.5 |

| Silicon, Si | 1 |

| Carbon, C | 0.10 |

| Phosphorous, P | 0.040 |

| Sulfur, S | 0.030 |

329 Stainless Steel Physical Properties

UNS S32900 is a very strong alloy with excellent tensile strength (up to 900MPa) and yield strength (up to 750MPa), depending on the application conditions. It also has great ductility and formability with good weldability thanks to its low carbon content. Additionally, this grade of stainless steel has very good thermal conductivity as well as superior heat resistance up to 870°C/ 1600°F.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.80 g/cm3 | 0.282 lb/in³ |

329 Stainless Steel Mechanical Properties

The mechanical properties of 329 stainless steel mainly depend on the heat treatment process used during manufacturing. After heat treatment processes like annealing or quenching, this grade can achieve improved hardness levels up to 30 HRC while still maintaining its excellent strength and ductility characteristics. This makes it particularly useful for applications where hard-wearing parts are required but must still be able to withstand heavy loads without breaking or cracking under pressure.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 725 MPa | 105000 psi |

| Tensile strength, yield (@0.2%) | 550 MPa | 79800 psi |

| Charpy impact | 54 J | 39.8 ft-lb |

| Elastic modulus | 190 – 210 GPa | 27557 – 30458 ksi |

| Poisson’s ratio | 0.27 – 0.30 | 0.27 – 0.30 |

| Elongation at break (in 50 mm) | 25% | 25% |

| Hardness, Brinell | 230 | 230 |

| Hardness, Knoop (converted from Brinell hardness) | 253 | 253 |

| Hardness, Rockwell B | 96 | 96 |

| Hardness, Rockwell C (converted from Brinell hardness) | 20 | 20 |

| Hardness, Vickers (converted from Brinell hardness) | 242 | 242 |

329 Stainless Steel Equivalents

- ASTM A240

- ASTM A268

- ASTM A789

- ASTM A790

- ASTM A511

- ASME SA268

- ASME SA268

- DIN 1.4460

329 Stainless Steel Uses

UNS S32900 is a primary metal alloy used in many applications across industries. Its ability to retain strength and resist corrosion makes it an ideal material for a variety of projects, from construction to food processing. In construction, its extraordinary tensile strength makes it a great choice for bolts and other structures that require stability when experiencing movement and vibration. Additionally, its excellent corrosion resistance has made it popular for chemical processing applications such as pipes, valves and pumps that have frequent contact with liquids or vapours. Lastly, 329 stainless steel is great for food processing as it can handle prolonged contact with liquids like acid-based foods or alcoholic beverages without suffering wear and tear or discolouration over time. Clearly, 329 stainless steel is one of the most useful metals available today due to its wide range of applications.

Conclusion

In conclusion, if you need a metal that offers superior corrosion resistance while also having great physical and mechanical properties, then consider using 329 stainless steel in your next project or application. Its high chromium content makes it highly resistant to corrosion, while its low carbon content gives it excellent strength when exposed to heat treatments such as annealing or quenching. Additionally, its superior hardness levels make it suitable for applications where hard-wearing parts are needed but must still be able to withstand heavy loads without breaking or cracking under pressure. All in all, this grade is perfect for projects requiring maximum performance from their materials.

![]()

![]()

![]()

![]()