-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

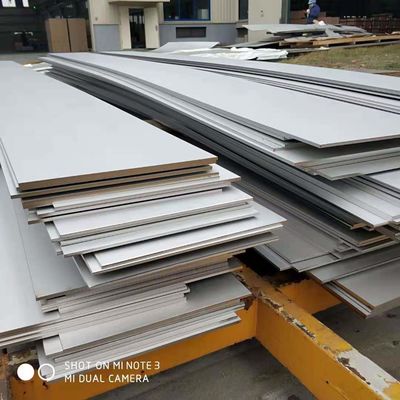

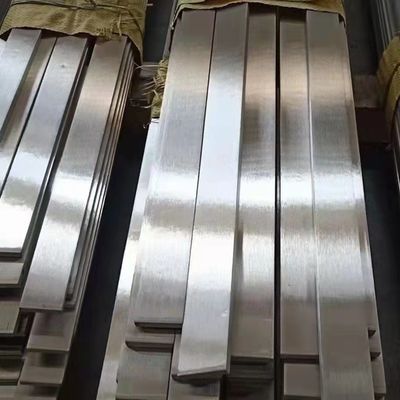

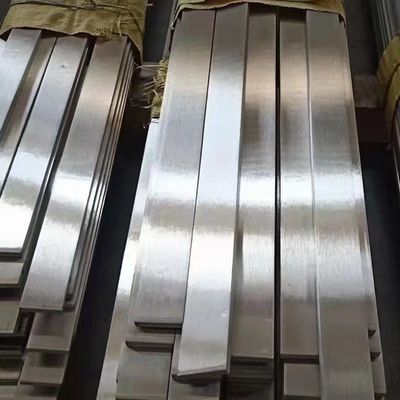

High Hardness Flat Stainless Steel Bar Hot Rolled 3.0-150mm 17-4PH

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 310S 2205 17-4PH |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Shape | Flat | Standard | ASTM EN GB JIS |

|---|---|---|---|

| Grade | 201 304 316L 310S 321 2205 2507.etc | Application | Construction,Industry,surgical Tools,seawater Equipment.,kitchenware |

| Length | Customers' Requirements,5.8m,6m,2m-6m,or As Required | Size | 10*3-200*20mm |

| Packing | Standard Seaworthy Package,In Wooden Cases(for FCL/ LCL Shipment) | Service | Cutting, Surface Finishing |

| Highlight | High Hardness Stainless Steel Bar,Stainless Steel Bar Hot Rolled,3.0mm stainless steel metal bar |

||

High Hardness 17-4PH Stainless Steel Flat Bar Hot Rolled Flat Bar Thickness 3.0 - 150mm

Products Specification of our stainless stainless flat bar

| Products | Stainless Steel Flat Bar |

| Size | 20*3mm - 200*20mm |

| Length | 6m or as request |

| Tech | hot rolled / cold rolled |

| Main Grade | 201 304 304L 309S 310S 316L 316Ti 410 420 430 2205 2507 904L17-4ph.etc |

| Standard | ASTN JIS GB EN |

| Service | cutting, surface finishing |

| MOQ | 500 kgs |

17-4 Stainless Steel (coming from the chemical makeup 17% chromium and 4% copper or UNS 17400) is a martensitic stainless grade that can be precipitation hardened through aging/heat treatment. 17-4 stainless steel, otherwise known as SAE Type 630 is frequently used with operations demanding high tensile strength and a middling level of corrosion resistance. 17-4 PH is the most used grade of martensitic precipitation hardenable alloys. 17-4 stainless steel is regarded as the most broadly formed precipitation hardening grade. Its intense tensile strength keeps its ductility and hardness at temperatures at nearly 600°F, while still demonstrating exceptional corrosion resistance in all conditions offered by Premium Alloys. Just as all martensitic metals, 17-4 is magnetic.

Resistance

17-4 stainless steel can reach large levels of hardness, durability, and strength through heat treatment. 17-4 PH resists corrosion superior to any of the basic stainless steels that can be hardened. It is resistant to industries where the steel may be exposed to petroleum and most foods. Exceptional resistance to decay at roughly 1100°F. 17-4 stainless steel PH demonstrates great machinability.

Processing

Superior hardness can be obtained from welding after heat treatment. Machining conditions differ with firmness of the element. Different levels of strength and hardness can be achieved depending on the temperature it is heat treated at. The ASTM designation is A564 and common conditions are H900, H1025, H1075, H1150, and H1150D.

Physical Properties

|

Condition

|

Tensile | Yield | Enlongation | Reduction of Area |

Hardness |

| H900 | 190 | 170 | 10 | 40 | 40-47 HRC |

| H1025 | 150 | 145 | 12 | 45 | 35-42 HRC |

| H1075 | 145 | 125 | 13 | 45 | 33-39 HRC |

| H1150 | 135 | 105 | 16 | 50 | 28-37 HRC |

| H1150D | 125 | 105 | 16 | 50 | 26-33 HRC |

Applications

- Oil and Gas

- Pump and Boat Shaft

- Seals

- Valves

- Petrochemical

- Aerospace

- Food Processing

- Paper / Pulp

- Jobs requiring hardness and corrosion resistance at temperatures below 600°F

Benefits

- Can be hardened to customize strength and hardness depending on the application

- High strength with moderate corrosion resistance

- Can be machined in solution treated and heat-treated conditions

- Retains its mechanical properties and corrosion resistance up to roughly ~600°F

- Great formability and weldability

- Withstands corrosive attack better than any of the standard hardenable (martensitic) stainless steels

- Superior resistance to corrosive material and high mechanical properties. This allows it to be used in marine environments.

- Can be designed in such a way to seal radioactive storage.

![]()

![]()

![]()

![]()

![]()