-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

X-750 Nickel Alloy UNS N07750 EN 2.4669

| Products | Nickel Alloy Plate | Grade | Inconel X-750 |

|---|---|---|---|

| Thickness | 0.6 - 30.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | X-750 Nickel Alloy,Nickel Alloy UNS N07750,EN 2.4669 inconel x 750 |

||

Alloy X-750 Nickel Base Alloy Inconel X-750 / UNS N07750 / EN 2.4669 Sheet and Plate

Products Specification

| Product Name | Nickel Alloy Plate & Sheet |

| Thinckness |

Cold rolled:0.3mm-3mm Hot rolled: 3.0mm-30mm |

| Standard Size | Cold Rolled 1000*2000mm 1219*2438mm 1500*3000mm |

| Hot Rolled 1500*6000mm 1800*6000mm 2000*6000mm | |

| Service | Cutting (laser cutting, plasma cutting, cutting machine), Bending, forged produce |

| Surface Service | Raw finishing (2B NO.1) Finishing(HL 8K Checkered.etc) |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Mainly Grade | ASTM Grade: Incoloy 800 / 800H ,Incoloy 825,Inconel 600 , Inconel 625 ,Inconel 718, Inconel X-750,Inconel690,Hastelloy B , Hastelloy B-2 , Hastelloy C276 , Hastelloy C4, Hastelloy C2000, ASME Grade: N08800 N08810 N08825 N06600 N06601 N06690 N10001 N10665 N10276 N06455 N06625 EN 1.4588 2.4858 2.4817 2.4642 2.4617 2.4819 2.461 2.4856 |

| Brand | TISCO BAOSTEEL ZPSS LISCO JISCO |

INCONEL alloy X-750 (UNS N07750/W. Nr. 2.4669) is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F. Alloy X-750 also has excellent properties down to cryogenic termperatures. Composition is shown in Table 1. The economics of INCONEL alloy X-750 coupled with its availability in all standard mill forms has resulted in applications in a wide variety of industrial fields. In gas turbines, it is used for rotor blades and wheels, bolts, and other structural members. INCONEL alloy X-750 is used extensively in rocket-engine thrust chambers. Airframe applications include thrust reversers and hot-air ducting systems. Large pressure vessels are formed from INCONEL alloy X-750. Other applications are heat-treating fixtures, forming tools, extrusion dies, and test machine grips. For springs and fasteners, INCONEL alloy X-750 is used from sub-zero to 1200°F

Inconel X750 offers the following key features:

- Good creep rupture strength at high temperatures

- Not as strong as Nimonic 90

- Very good at cryogenic temperatures

- Age hardenable

- High temperature dynamic applications

Chemical Composition of Inconel X-750 Alloy

The chemical composition of Inconel X750 is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| C | – | 0.08 |

| Mn | – | 1.00 |

| Si | – | 0.50 |

| S | – | 0.01 |

| Cr | 14.00 | 17.00 |

| Ni | 70.00 | – |

| Nb/Cb | 0.70 | 1.20 |

| Ti | 2.25 | 2.75 |

| Al | 0.40 | 1.00 |

| Fe | 5.00 | 9.00 |

| Co | – | 1.00 |

| Ta | – | 0.05 |

| Cu | – | 0.50 |

Alloy Details

Inconel X750 density, melting point, coefficient of expansion, modulus of rigidity, and elasticity is indicated in the table below:

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 8.28g/cm³ | 1430 °C | 12.6 μm/m °C (20 – 100 °C) | 75.8 kN/mm² | 218.0 kN/mm² (Spring Temper + Aged) 212.4 kN/mm² (Spring Temper + 3 Part Heat Treated) 213.7 kN/mm² (No.1 Spring Temper + Aged) |

| 0.299 lb/in³ | 2600 °F | 7.0 x 10-6 in/in °F (70 – 212 °F) | 10994 ksi | 31619 ksi (Spring Temper + Aged) 30806 ksi (Spring Temper + 3 Part Heat Treated) 30995 ksi (No.1 Spring Temper + Aged) |

Typical Applications

Inconel X750 is known to be suitable for the following applications:

- Nuclear reactors

- Gas turbines

- Rocket engines

- Pressure vessels

- Aircraft structures

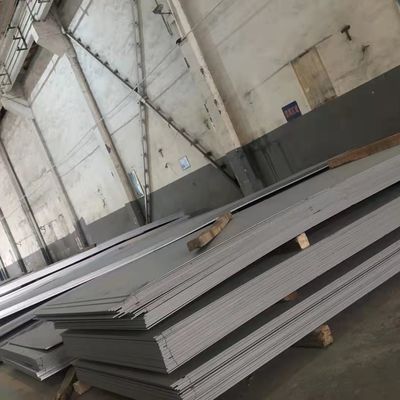

Products Show

![]()

![]()

![]()

![]()

![]()