-

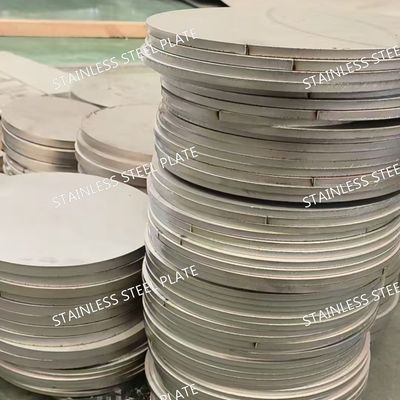

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

Стальная пластина

-

стальной круглый бар

-

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

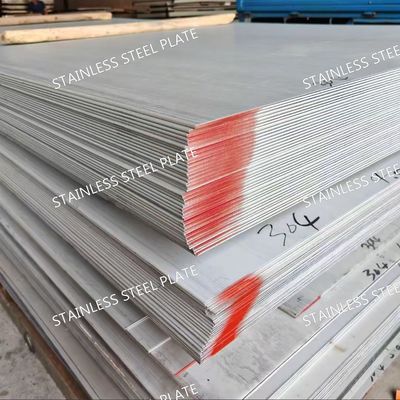

Плита из нержавеющей стали 317L, прокатаная холодно и горячо, для применения в теплообменниках

| Место происхождения | Китай |

|---|---|

| Фирменное наименование | BAOSTEEL TISCO |

| Сертификация | ISO |

| Номер модели | 317L / S31703 |

| Количество мин заказа | 50 кг |

| Цена | 5 - 8 USD/Kg |

| Упаковывая детали | стандартная упаковка для экспорта |

| Время доставки | 5 - 12 дней на основе количества |

| Условия оплаты | Л/К, Т/Т, Вестерн Юнион |

| Поставка способности | 20ton в неделю |

| Продукты | листы из нержавеющей стали | Оценка | 317Л/С31703 |

|---|---|---|---|

| Толщина | 1,0-80,0 мм | Технический | холоднокатаный, горячекатаный, кованый |

| Ширина | 1000mm 1219mm 1500mm или таможни как запрос | Поверхность | 2B БА No.1 |

| Стандартный | DIN EN ASTM GB JIS | минимальный заказ | 1 тонна |

| Выделить | Плита из нержавеющей стали 317L,прокатана холодом,горячекатаная плита нержавеющей стали 317l |

||

Плита из нержавеющей стали 317L, прокатаная холодно и горячо, для применения в теплообменниках

Спецификации листового состава из нержавеющей стали

| Имя | Лист из нержавеющей стали 317L |

| Наш класс |

Серия 200: 201 202 Серия 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Серия 400: 409L410,410S,416,420,430,431436 л.439,441,443,444,445,446 Сверхнержавеющая сталь: 904L,926254SMO, 654SMO, 15-5PH, 17-4PH, 17-7PH и т.д. Сплав никеля: С276, С22, Г35, Сплав Х, Монел 400, К500, Инконел 600,601,617,625,718Инколай 800,800H,800HT,825. и т.д. |

| Техника | Горячее прокат, холодное прокат, подделка |

| Стандартный | JIS, AISI, ASTM, DIN, TUV, BV, SUS и т.д. |

| Толщина | 0.1 80 мм |

| Диапазон ширины | 10 мм 2000 мм |

| Длина | Настраиваемый |

| Заканчивай. | 2B, BA, нет.4, 8K, Чистили, Линию волос, ПВД покрытие, пескоструй |

| Служба | Лазерная резка, изгиб |

| Образец | Доступно |

Введение

В области промышленных теплообменников выбор материала имеет первостепенное значение для обеспечения долгосрочной производительности, эффективности и экономичности.317L из нержавеющей стали, приобрела значительную популярность из-за своей исключительной коррозионной стойкости, высокой температурной выносливости и механических свойств.холодно прокачанныеигорячо прокачанныеПлиты из нержавеющей стали 317L обеспечивают превосходный баланс прочности и производительности.

Этот универсальный сплав, разработанный для требовательных условий, таких как химические перерабатывающие заводы, электростанции и опреснительные установки, выделяется своей устойчивостью к всасыванию,коррозия трещинС его высоким содержанием молибдена и низким содержанием углерода,317Lособенно подходит для высокотемпературных операций, когда теплообменники постоянно контактируют с агрессивными жидкостями, кислотами и газами.свойства, и примененияхолодно прокачанныеигорячекатаные пластины из нержавеющей стали 317Lв системах теплообменников.

Что такое 317L нержавеющая сталь?

317L - этоаустенитическая нержавеющая стальсплав, содержащий высокие уровнихром(18-20%),Никель(11-15%) имолибден(3-4%). Это сочетание дает стали повышенную устойчивость к различным коррозионным средам, особенно хлоридам и кислотным растворам.Обозначение "L" означает, что этот класс имеет низкое содержание углерода (≤ 00,03%), что значительно снижает риск осаждения карбида и последующей межгранулярной коррозии после сварки или воздействия высоких температур.Это делает 317L особенно подходящим для теплообменников в коррозионной среде.

Оба.холодно прокачанныеигорячо прокачанныеВерсии 317L предлагают различные преимущества на основе их производственных процессов, но обе формы превосходят по коррозионной стойкости и идеально подходят для применения в теплообменниках.

Холоднопрокатные и горячопрокатные пластины из нержавеющей стали 317L

Плита из нержавеющей стали 317L, прокатана холодом

Холодная прокатка включает в себя прохождение нержавеющей стали через ролики при комнатной температуре, чтобы уменьшить ее толщину и улучшить отделку поверхности.В результате получается высокоточное изображениеХолоднокатаные пластины 317L обычно используются в приложениях, требующих точных допустимых расстояний и высококачественной отделки.например, в теплообменниках, где площадь поверхности и эффективность теплопередачи имеют решающее значение.

Преимущества холоднокатаной пластины 317L

-

Гладкая поверхность

Холодная прокатка обеспечивает тонкую гладкую поверхность (обычно 2B или No.4), которая идеально подходит для теплообменников, где чистые, полированные поверхности помогают улучшить теплопроводность и уменьшить загрязнение. -

Улучшенные механические свойства

Процесс холодной обработки увеличивает прочность и твердость материала.Это делает холоднокатаные пластины 317L подходящими для применения, где необходима высокая механическая прочность и устойчивость к деформации. -

Точные размеры

Холоднокатаные пластины обладают отличной точностью измерений, что имеет решающее значение для изготовления компонентов, которые должны точно вписываться в системы теплообменников.Тонкие допустимые отклонения холоднокатаных плит обеспечивают эффективное, надежная работа. -

Улучшенная коррозионная устойчивость

Холодное прокатение повышает защитный слой оксида на поверхности, еще больше повышая устойчивость к коррозии,особенно в агрессивной среде, такой как теплообменники в химических или морских приложениях.

Пластина из нержавеющей стали 317L, горячекатаная

Горячая прокатка - это производственный процесс, при котором сталь нагревается выше температуры ее рекристаллизации, а затем проходит через ролики для уменьшения ее толщины.Полученные горячо прокатаные пластины 317L имеют более грубую поверхность и могут иметь большие различия в толщине, но они являются экономически эффективными и предлагают отличные механические свойства для крупномасштабных приложений.

Преимущества горячо прокатаной пластины 317L

-

Эффективное использование для крупных приложений

Горячая прокатка, как правило, более экономична, чем холодная прокатка, что делает ее хорошим вариантом для больших теплообменников или систем, где требуется большой объем материала. -

Лучшая формальность

Горячекатаные пластины 317L могут быть легко обработаны путем ковки, изгиба и сварки, что выгодно для специально разработанных теплообменников со сложной геометрией. -

Высокая устойчивость к коррозии при высоких температурах

Горячекатаные пластины 317L обладают отличной стойкостью к высокой температуре, что имеет решающее значение для теплообменников, работающих в экстремальных тепловых условиях.такие, как те, которые встречаются в нефтехимических нефтеперерабатывающих заводах или электростанциях. -

Идеально подходит для тяжелых применений

Хотя поверхность может быть не такой гладкой, как холоднокатаные пластины,горячекатаные пластины хорошо подходят для применения, где механическая прочность и устойчивость к высокому давлению более важны, чем эстетика поверхности.

Ключевые свойства нержавеющей стали 317L для применения в теплообменниках

Оба.холодно прокачанныеигорячекатаные пластины из нержавеющей стали 317Lобладают замечательными свойствами, которые делают их идеальными для теплообменников:

| Недвижимость | Стоимость (типичная) | Значение для теплообменников |

|---|---|---|

| Прочность на растяжение | 515 MPa (75 ksi) | Обеспечивает долговечность при механических нагрузках и давлении. |

| Сила урожая | 205 МПа (30 кси) | Поддерживает структурную целостность под внутренним давлением. |

| Удлинение | 35~40% | Означает высокую пластичность, важную для формования и сварки. |

| Твердость | ≤ 217 HB | Устойчивость к износу поверхности. |

| Устойчивость к коррозии | Отлично. | Выдерживает агрессивные химические и кислотные среды. |

| Сопротивление в ямах | Высокий (PREN > 35) | Предотвращает локальную коррозию в условиях, богатых соляной или хлоридной кислотой. |

| Теплопроводность | 16 W/m·K | Позволяет эффективно передавать тепло в системах обменников. |

| Плотность | 70,9 г/см3 | Типичный для аустенитной нержавеющей стали; важен для расчета веса. |

| Коэффициент теплового расширения | 160,0 × 10−6 /°C | Обеспечивает стабильность измерений при колебаниях температуры. |

Сочетание этих свойств позволяет317L из нержавеющей сталиэффективно работать в теплообменниках, обеспечивая надежное и долговечное обслуживание даже в требовательных тепловых и химических условиях.

Применение пластин из нержавеющей стали 317L в теплообменниках

Это...высокая коррозионная стойкостьитепловая устойчивостьиз нержавеющей стали 317L, что делает его предпочтительным материалом для различных типов теплообменников, используемых в таких отраслях промышленности, как нефтехимия, производство энергии, опреснение, переработка продуктов питания,и фармацевтические препараты.

1.Химические теплообменники

Теплообменники в химических заводах подвергаются воздействию очень агрессивных химических веществ, включая кислоты, щелочи и растворители.317L из нержавеющей сталиявляется особенно эффективным в этих приложениях из-за его способности противостоять нападению серной кислоты, соляной кислоты и других коррозионных веществ.Холодный прокат 317L обычно используется для применений, требующих высоких стандартов отделки поверхности, такие как те, которые включают теплообменники в реакторах, конденсаторах и испарителях.

2.Теплообменники электростанций

В тепловых электростанциях теплообменники обрабатывают высокие температуры и пар, часто в присутствии хлоридов или других агрессивных жидкостей.В этих системах используются горячо прокатаные пластины из нержавеющей стали 317L из-за их прочностиЭтот материал помогает продлить срок службы оборудования и повысить энергоэффективность.

3.Заводы опреснения

В установках по опреснению морской воды для дистилляции и других процессов разделения используются теплообменники.Нержавеющая сталь 317L идеально подходит для этих применений из-за ее отличной стойкости к коррозии, вызванной хлоридом.Холоднокатаные пластины часто используются в областях, требующих гладкой, не загрязняющей поверхности, в то время как горячекатаные пластины могут быть выбраны для более крупных компонентов или систем под высоким тепловым напряжением.

4.Теплообменники пищевой и молочной промышленности

Теплообменники, используемые в пищевой и напиточной промышленности, должны соответствовать строгим стандартам гигиены, а также выдерживать воздействие кислотных растворов, таких как лимонная кислота или молочная кислота.Высокая коррозионная стойкость 317L обеспечивает длительный срок службыХолоднокатаные пластины из нержавеющей стали 317L пользуются предпочтением в пищевых продуктах из-за их гладкой отделки и простоты очистки.

5.Фармацевтическая промышленность

В фармацевтических заводах теплообменники должны обрабатывать как высокие температуры, так и коррозионные химические вещества, такие как растворители и чистящие средства.317L нержавеющая сталь обеспечивает необходимую коррозионную стойкость, особенно в местах, где материал должен выдерживать длительное воздействие суровых химических веществ.что имеет решающее значение для поддержания целостности фармацевтических процессов.

Сравнение холоднокатаной и горячокатаной нержавеющей стали 317L для теплообменников

| Имущество / характеристика | Холодно проката 317L | Горячо проката 317L |

|---|---|---|

| Поверхностная отделка | Гладкий, полированный (2B, No 4) | Более грубая, мельная отделка |

| Механическая прочность | Более высокая прочность и твердость | Более низкая прочность, чем холодная прокатка |

| Точность измерений | Точные, строгие допуски | Более большие допустимые отклонения, менее точные |

| Устойчивость к коррозии | Улучшенная защита поверхностей | Отлично, но в некоторых случаях немного ниже, чем холодно проката |

| Легкость изготовления | Труднее сформировать, но идеально подходит для мелких деталей | Легче сформировать и сварка, подходит для более крупных, сложных конструкций |

| Стоимость | Дороже |

![]()

![]()

![]()

![]()