-

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

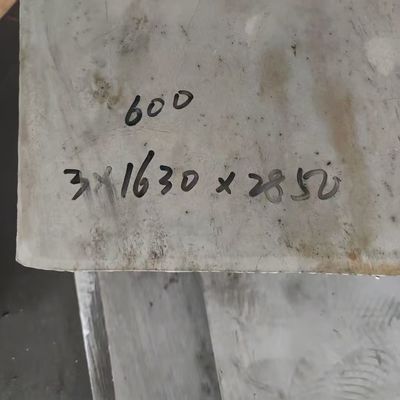

Стальная пластина

-

стальной круглый бар

-

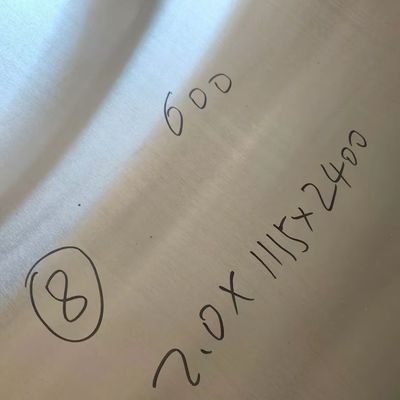

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Laser Cutting Inconel 617 Plate (0.5mm-100mm Thickness) Precision-Cut for Power Generation Equipment

| Место происхождения | КИТАЙ |

|---|---|

| Фирменное наименование | DELTA |

| Сертификация | ISO |

| Номер модели | Inconel 617 |

| Количество мин заказа | 500 кг |

| Цена | 40-45 USD/Kg |

| Упаковывая детали | стандартная упаковка для экспорта |

| Время доставки | 5 - 12 дней на основе количества |

| Условия оплаты | L/C, T/T, Western Union |

| Поставка способности | 3 тонны в неделю |

Свяжитесь я бесплатно образцы и талоны.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Если вы имеете любую заботу, то мы предусматриваем 24-часовую интерактивную справку.

x| Продукты | Лист & плита сплава никеля | Оценка | Inconel 617 |

|---|---|---|---|

| Толщина | 0.5 - 30.0mm | Стандартный размер | 1000*2000mm 1219*2438mm |

| Стандартный | Astm en | Услуга | Резка |

| Загрузочный порт | Шанхайский порт | Поверхность | 2B NO.1 NO.4 NO.8 |

| Выделить | Laser cut Inconel 617 plate,Precision-cut nickel alloy plate,Inconel 617 power generation plate |

||

Laser Cutting Inconel 617 Plate (0.5mm-100mm Thickness) Precision-Cut for Power Generation Equipment

Products Specification

| Products Name | Inconel 617 Nickel Alloy Sheet Plate |

| Thickness | Cold rolled: 0.5 - 3.0mm Hot rolled 4.0 - 30.0mm |

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Other Grade | Hastelloy C22 C4 X C276 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 617 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Laser Cutting Inconel 617 Plate (0.5mm-100mm Thickness) Precision-Cut for Power Generation Equipment

Inconel 617 is a highly durable and heat-resistant nickel-chromium alloy known for its outstanding performance in extreme environments, particularly in the power generation industry. This superalloy, available in plates ranging from 0.5mm to 100mm in thickness, is ideal for precision laser cutting, offering a reliable solution for components in high-temperature applications like gas turbines, industrial furnaces, and other power generation equipment.

This article delves into the key properties, standards, applications, and packaging/transport details of Inconel 617 plates, focusing on their use in critical power generation applications.

Inconel 617 Plate Specifications and Properties

Material: Inconel 617 (NiCrCoMo)

Thickness Range: 0.5mm - 100mm

Shape: Plate

Standard: ASTM B168, ASME SB168

Density: 8.91 g/cm³

Melting Point: Approx. 1350°C (2462°F)

Chemical Composition

Inconel 617 is primarily composed of nickel (Ni) and chromium (Cr), with added elements to enhance its performance at high temperatures. The chemical composition of Inconel 617 is as follows:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 50.0 - 60.0 |

| Chromium (Cr) | 20.0 - 23.0 |

| Molybdenum (Mo) | 8.0 - 10.0 |

| Cobalt (Co) | 10.0 max |

| Iron (Fe) | Balance |

| Aluminum (Al) | 1.0 max |

| Titanium (Ti) | 0.5 max |

| Silicon (Si) | 0.5 max |

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 1.0 max |

The combination of nickel and chromium makes Inconel 617 exceptionally resistant to oxidation and carburization at elevated temperatures, which is essential in power generation applications where high heat and corrosive environments are common.

Mechanical Properties

Inconel 617 exhibits remarkable mechanical properties that make it ideal for high-stress, high-temperature applications. The key mechanical properties are as follows:

| Property | Value |

|---|---|

| Tensile Strength | 700 MPa (102 ksi) |

| Yield Strength (0.2% Offset) | 250 MPa (36.3 ksi) |

| Elongation | 30% min (50mm gauge length) |

| Hardness | HRB 90 max |

| Modulus of Elasticity | 207 GPa (30 x 10^6 psi) |

| Poisson's Ratio | 0.31 |

These mechanical properties allow Inconel 617 to maintain structural integrity even in extreme operating conditions, making it suitable for high-performance applications in the power generation sector.

Thermal Properties

Inconel 617 can perform optimally at temperatures up to 2000°F (1093°C) while maintaining its strength and resistance to oxidation and corrosion. This makes it ideal for use in high-temperature environments such as gas turbines, combustor components, and heat exchangers.

Laser Cutting Inconel 617 Plate

Laser cutting is a highly precise method used to shape Inconel 617 plates for various applications. The laser cutting process allows for complex geometries with tight tolerances, making it a preferred choice for producing components used in power generation and aerospace industries.

Advantages of Laser Cutting Inconel 617 Plates:

-

Precision: Laser cutting provides high-precision edges with minimal heat distortion, which is crucial for maintaining the alloy’s integrity.

-

Clean Cuts: The process results in smooth, burr-free edges, reducing the need for post-processing and ensuring the alloy’s desired mechanical properties are retained.

-

Complex Shapes: Laser cutting allows for the creation of intricate designs and shapes that are difficult to achieve using traditional cutting methods.

-

Minimal Material Waste: The focused laser beam minimizes material waste, improving cost efficiency.

Standards and Specifications

Inconel 617 plates are manufactured according to internationally recognized standards, ensuring quality and consistency across all products. The primary standards for Inconel 617 include:

-

ASTM B168: This standard defines the requirements for nickel-chromium alloys, including Inconel 617, for use in gas turbines and other high-temperature applications. The standard specifies mechanical properties, chemical composition, and dimensions for plates and sheets.

-

ASME SB168: This is the specification for the material used in pressure vessel applications, ensuring that Inconel 617 meets the demands of industries requiring high strength and corrosion resistance at elevated temperatures.

These standards ensure that Inconel 617 is suitable for use in critical power generation applications where safety and reliability are paramount.

Similar Alloys to Inconel 617

Several other alloys share similar properties with Inconel 617 and can be considered alternatives depending on the specific requirements of an application. Some of the common alloys similar to Inconel 617 include:

-

Inconel 625: Known for its excellent fatigue and thermal-fatigue strength, Inconel 625 is highly resistant to oxidation and corrosion in aggressive environments.

-

Incoloy 800HT: A nickel-iron-chromium alloy with good oxidation and carburization resistance, often used in high-temperature applications.

-

Inconel 718: A high-strength, corrosion-resistant alloy used primarily in aerospace and gas turbine applications, especially in lower-temperature environments.

Although these alloys exhibit similar properties to Inconel 617, Inconel 617’s higher molybdenum content offers superior resistance to carburization and oxidation at very high temperatures, making it ideal for applications in gas turbines and industrial furnaces.

Applications of Inconel 617 Plate

Inconel 617 is used in a variety of applications that require high strength, excellent corrosion resistance, and stability at high temperatures. Some of the most common uses include:

-

Gas Turbine Components: Inconel 617 is widely used in the manufacturing of turbine blades, vanes, and other components exposed to extreme temperatures and stresses in power generation plants.

-

Heat Exchangers: Due to its resistance to both oxidation and carburization, Inconel 617 is ideal for high-temperature heat exchangers in petrochemical and power generation industries.

-

Combustor Linings: Inconel 617 is used to manufacture combustor linings and transition ducts, which are subjected to severe thermal stresses.

-

Furnace Components: This alloy is also used for components in furnaces, including radiant tubes and furnace baskets, which are exposed to high-temperature gases.

-

Aerospace Applications: Components such as turbine seals and exhaust components benefit from Inconel 617’s heat resistance and long-term stability.

In power generation equipment, these applications help ensure that the systems remain reliable and efficient even under the harshest operating conditions.

Packaging and Transportation

When it comes to packaging and transportation, it is essential to ensure that Inconel 617 plates are delivered in perfect condition to avoid any damage during transit. Typical packaging and transportation procedures include:

-

Packaging: Plates are usually packaged in wooden crates or pallets to prevent damage during shipping. For smaller sizes, protective plastic or metal covers may be used.

-

Labeling: Each package will be clearly labeled with the material type, thickness, and quantity, as well as the relevant ASTM or ASME standards, to ensure that all specifications are met.

-

Shipping: Inconel 617 plates are typically shipped by air, sea, or road depending on the distance and urgency of the order. International shipments require proper documentation for customs clearance, and delivery times are usually within 7-10 business days for domestic orders and up to 30 days for international shipments.

-

Handling: Given the material's value and precision, careful handling is required during transit to prevent any impact or bending.

![]()

![]()

![]()

![]()