-

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

Стальная пластина

-

стальной круглый бар

-

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Hot Rolled Hastelloy C-22 Round Bar With Excellent Corrosion Resistance Diameter 10 - 350mm

| Место происхождения | КИТАЙ |

|---|---|

| Фирменное наименование | DELTA |

| Сертификация | ISO |

| Номер модели | Hastelloy C-22 |

| Количество мин заказа | 10 кг |

| Цена | 40 - 50 USD/Kg |

| Упаковывая детали | стандартная упаковка для экспорта |

| Время доставки | 5 - 12 дней на основе количества |

| Условия оплаты | L/C, T/T, Western Union |

| Поставка способности | 3 тонны в неделю |

| Продукция | Круглый пруток Hastelloy C-22 | Оценка | Hastelloy C22 |

|---|---|---|---|

| Диаметр | 10 - 350mm | Длина | настройка резки любой длины по запросу |

| Стандартный | Astm en | Услуга | Резка |

| Загрузочный порт | Шанхайский порт | Поверхность | яркий, черный |

| Выделить | Hot Rolled Hastelloy C-22 Round Bar,Hastelloy C-22 corrosion resistant bar,Nickel alloy round bar 10-350mm |

||

Hot Rolled Hastelloy C-22 Round Bar With Excellent Corrosion Resistance Diameter 10 - 350mm

More Specification Informations

| Products Name | Hastelloy C22 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hot Rolled Hastelloy C-22 Round Bar With Excellent Corrosion Resistance Diameter 10 - 350mm

Product Overview

Hot Rolled Hastelloy C-22 Round Bar represents the pinnacle of corrosion-resistant alloy technology, specifically engineered to perform in the most aggressive industrial environments. This versatile nickel-chromium-molybdenum-tungsten alloy delivers exceptional performance in handling both oxidizing and reducing media, making it an ideal choice for critical applications across chemical processing, pollution control, and energy industries. With available diameters ranging from 10mm to 350mm, our round bars offer unparalleled versatility for manufacturing, maintenance, and repair operations in corrosive environments. The hot-rolled manufacturing process ensures optimal mechanical properties and uniform microstructure throughout the bar, providing consistent performance even in the most demanding conditions where lesser materials would rapidly fail.

The exceptional qualities of Hastelloy C-22 stem from its precisely balanced chemical composition, which includes carefully controlled percentages of chromium, molybdenum, and tungsten that work synergistically to create a robust protective layer against corrosive attack. Unlike standard stainless steels or earlier-generation nickel alloys that may fail in specific corrosive environments, Hastelloy C-22 offers comprehensive corrosion resistance across a broad spectrum of media, including acids, chlorides, and other aggressive chemicals. This round bar maintains excellent welding characteristics and thermal stability, resisting the formation of harmful precipitates during fabrication and welding operations. Whether you're designing new equipment or maintaining existing infrastructure, our Hot Rolled Hastelloy C-22 Round Bar provides the reliable longevity necessary to minimize downtime and maximize operational efficiency in corrosive applications.

Key Features

-

Exceptional Corrosion Resistance: Delivers outstanding performance in both oxidizing and reducing environments, including resistance to pitting, crevice corrosion, and stress corrosion cracking . The alloy's balanced composition provides superior resistance to wet chlorine, hypochlorite, and sulfuric acid solutions, making it suitable for the harshest chemical processing conditions.

-

Optimized Mechanical Properties: Hot-rolled production yields superior tensile strength (≥690 MPa) and yield strength (≥310 MPa) while maintaining excellent elongation (≥45%) for forming and fabrication operations . The consistent mechanical properties throughout the cross-section ensure predictable performance in critical applications.

-

High-Temperature Capability: Maintains structural integrity and corrosion resistance at elevated temperatures up to 600°C for continuous service, with short-term tolerance to 1000°C, making it suitable for heat exchangers, furnace components, and high-temperature processing equipment .

-

Enhanced Versatility: Suitable for a wide range of manufacturing processes including machining, welding, and forming operations. The alloy's low carbon content minimizes susceptibility to carbide precipitation during welding, maintaining corrosion resistance in welded fabrications .

-

Broad Chemical Compatibility: Performs excellently in diverse corrosive media including hydrochloric acid, sulfuric acid, phosphoric acid, chlorine-containing environments, and complex chemical mixtures . This universal corrosion resistance reduces material selection challenges for equipment handling multiple chemical streams.

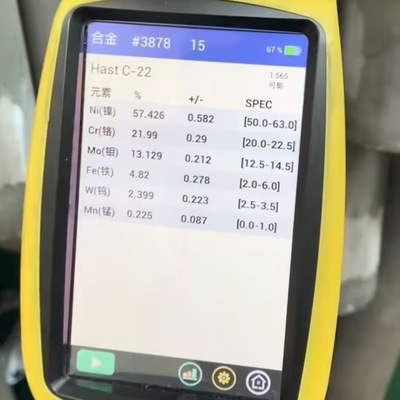

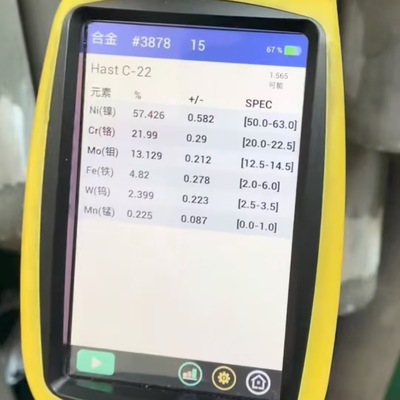

Chemical Composition

The outstanding corrosion resistance of Hot Rolled Hastelloy C-22 Round Bar stems from its meticulously balanced chemical composition. Each element plays a crucial role in developing the alloy's protective characteristics and mechanical properties:

*Table: Chemical Composition of Hastelloy C-22 Round Bar*

| Element | Percentage (%) | Function |

|---|---|---|

| Nickel (Ni) | Balance (approx. 56%) | Provides fundamental corrosion resistance and maintains alloy stability across temperature ranges |

| Chromium (Cr) | 20.0 - 22.5 | Enhances resistance to oxidizing media and formation of protective oxide layers |

| Molybdenum (Mo) | 12.5 - 14.5 | Improves resistance to reducing acids and localized corrosion |

| Tungsten (W) | 2.5 - 3.5 | Synergistically works with molybdenum to enhance overall corrosion resistance |

| Iron (Fe) | 2.0 - 6.0 | Maintains cost-effectiveness while preserving corrosion performance |

| Cobalt (Co) | ≤ 2.5 | Optimizes high-temperature characteristics |

| Carbon (C) | ≤ 0.015 | Minimizes carbide precipitation to maintain corrosion resistance in welded structures |

| Manganese (Mn) | ≤ 0.50 | Supports metallurgical processing and cleanliness |

| Silicon (Si) | ≤ 0.08 | Controls fluidity during melting and prevents harmful phase formation |

| Vanadium (V) | ≤ 0.35 | Contributes to microstructural stability |

| Phosphorus (P) | ≤ 0.02 | Maintains purity and reduces susceptibility to localized attack |

| Sulfur (S) | ≤ 0.02 | Enhances purity and improves hot workability |

This optimized composition creates a balanced alloy system that resists a wider range of corrosive conditions than earlier nickel-chromium-molybdenum alloys. The careful control of carbon and silicon content at very low levels significantly enhances resistance to sensitization during welding and thermal processing . The combination of chromium, molybdenum, and tungsten provides a synergistic protective effect against localized corrosion, making it particularly effective in chloride-containing environments where other materials would suffer pitting and crevice corrosion attack.

Mechanical Properties

Hot Rolled Hastelloy C-22 Round Bar exhibits a combination of high strength and good ductility, making it suitable for pressure vessel applications, valve components, pump parts, and other critical equipment where both mechanical integrity and corrosion resistance are essential. The hot-rolling process imparts a uniform grain structure that ensures consistent mechanical properties throughout the product length and cross-section.

*Table: Mechanical Properties of Hot Rolled Hastelloy C-22 Round Bar*

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength | ≥ 690 MPa | ASTM E8/E8M |

| Yield Strength (0.2% Offset) | ≥ 310 MPa | ASTM E8/E8M |

| Elongation (in 50mm) | ≥ 45% | ASTM E8/E8M |

| Hardness (Brinell) | ≤ 220 HB | ASTM E10 |

| Density | 8.69 g/cm³ | - |

| Melting Point | 1325-1370 °C | - |

| Modulus of Elasticity | 210 GPa | ASTM E111 |

The excellent elongation (≥45%) facilitates cold forming operations such as bending and swaging, while the high tensile strength provides structural capability for loaded applications . The combination of these mechanical properties with outstanding corrosion resistance makes Hastelloy C-22 round bar particularly valuable for applications such as fasteners, mixer shafts, and agitators that must withstand both mechanical stress and corrosive environments simultaneously.

Product Specifications

Our Hot Rolled Hastelloy C-22 Round Bar is available in a comprehensive range of sizes and produced according to international standards to ensure quality and performance consistency across applications.

*Table: Standard Specifications of Hot Rolled Hastelloy C-22 Round Bar*

| Parameter | Specification |

|---|---|

| Available Diameters | 10mm - 350mm |

| Standard Lengths | 2000mm - 6000mm (Custom lengths available) |

| Manufacturing Standards | ASTM B574, ASME SB574, DIN 17744 No. 2.4602 |

| UNS Designation | N06022 |

| Surface Finish | Hot-rolled, black surface or polished finish available |

| Form | Straight lengths |

| Equivalent Designations | WERKSTOFF NR. 2.4602, NW 6022, NiCr21Mo14W |

The extensive diameter range from 10mm to 350mm ensures suitability for diverse applications from precision instrumentation components to heavy industrial machinery parts . Our round bars are supplied with strict dimensional control, ensuring consistency for automated machining operations and precision applications. The surface condition is carefully monitored to minimize imperfections that could initiate corrosion in service environments.

Applications

Hot Rolled Hastelloy C-22 Round Bar finds application across multiple industries where corrosion resistance is critical to operational reliability and safety:

-

Chemical Processing Industry: Used in reactors, heat exchangers, distillation columns, and piping systems handling aggressive media including sulfuric acid, hydrochloric acid, and phosphoric acid -8. The material's resistance to both oxidizing and reducing conditions makes it particularly valuable in processes with changing chemistry.

-

Pollution Control Equipment: Ideal for flue gas desulfurization systems, scrubbers, waste incineration plants, and wastewater treatment facilities where chlorides and other corrosive species are present -7-8. The alloy withstands the acidic condensates that form in these environments.

-

Pharmaceutical and Fine Chemical Production: Employed in reactors, mixing systems, and transfer lines where product purity must be maintained while handling corrosive intermediates and cleaning agents . The alloy's smooth surface finish and resistance to multiple chemical agents make it suitable for GMP-compliant facilities.

-

Pulp and Paper Industry: Used in digesters, bleach plants, and chemical recovery systems where chloride-containing liquors and acidic conditions would rapidly degrade less resistant materials .

-

Marine and Offshore Applications: Suitable for seawater-cooled heat exchangers, pump shafts, valve components, and fasteners in offshore platforms and shipbuilding where resistance to pitting and crevice corrosion in chloride environments is essential .

-

Nuclear Industry: Applied in fuel reprocessing, nuclear waste treatment, and containment systems where resistance to radioactive chemical solutions is required .

-

Geothermal and Power Generation: Used in geothermal well components, steam turbine parts, and cooling system elements where high temperatures and corrosive contaminants are present .

The versatile performance of Hastelloy C-22 across such diverse applications stems from its balanced composition, which provides more reliable performance than older alloys when exposed to complex or fluctuating chemical environments . This reduces the risk of unexpected failure and extends service life in critical equipment.

Quality Assurance

We maintain stringent quality control throughout the manufacturing process of our Hot Rolled Hastelloy C-22 Round Bar to ensure consistent performance and reliability:

-

Material Traceability: Full heat-by-heat traceability with mill test certificates confirming chemical composition and mechanical properties according to specified standards .

-

Advanced Manufacturing: Production using vacuum melting processes followed by hot rolling under controlled conditions to ensure uniform microstructure and properties .

-

Comprehensive Testing: Ultrasonic testing available to detect internal discontinuities, along with dimensional verification and surface quality inspection.

-

Standard Compliance: Compliance with ASTM, ASME, DIN, and other international standards to ensure global acceptability .

-

Certification Support: Provision of necessary documentation including material test certificates, inspection reports, and certificates of conformity to support customer qualification processes.

Our quality management system ensures that each shipment meets the specified requirements for chemical, mechanical, and dimensional characteristics, providing confidence in the material's performance in your critical applications.

Why Choose Our Product?

When you select our Hot Rolled Hastelloy C-22 Round Bar, you're investing in:

-

Proven Performance: Demonstrated success across multiple industries in the most challenging environments

-

Technical Expertise: Comprehensive support in material selection, fabrication guidelines, and application engineering to optimize performance

-

Supply Flexibility: Wide size range with capability for custom dimensions and rapid delivery to meet project schedules

-

Cost Efficiency: Extended service life reduces replacement frequency and maintenance costs despite higher initial investment than conventional materials

-

Sustainability: Long service life and recyclability contribute to environmental performance and reduced lifecycle impact

Hot Rolled Hastelloy C-22 Round Bar provides an optimal balance of corrosion resistance, mechanical properties, and fabricability for demanding applications. The hot-rolled condition offers an economical solution for applications where the superior surface finish of cold-finished products is not essential, while still providing the excellent corrosion resistance and mechanical performance characteristic of this premium alloy.

Ordering Information

To place an order or request additional technical information about our Hot Rolled Hastelloy C-22 Round Bar, please contact our sales team with the following details:

-

Required diameter and tolerance

-

Required length (standard or custom)

-

Quantity (pieces or weight)

-

Surface finish requirements

-

Certification requirements

-

Destination and delivery schedule

We offer flexible packaging options including wooden crates for international shipments to ensure product protection during transit . Our technical team is available to provide guidance on material selection, fabrication practices, and application optimization to ensure successful implementation of Hastelloy C-22 in your specific operating environment.

Contact us today to discuss your requirements and experience why our Hot Rolled Hastelloy C-22 Round Bar is the preferred choice for engineers facing corrosion challenges across multiple industries.

![]()

![]()

![]()

![]()