Все продукты

-

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

Стальная пластина

-

стальной круглый бар

-

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

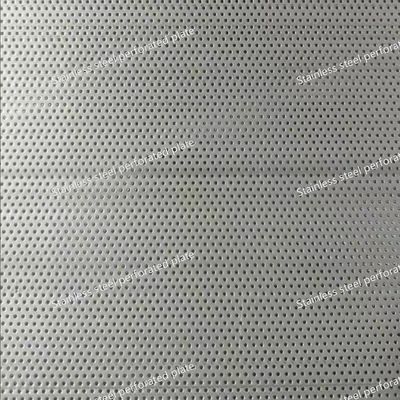

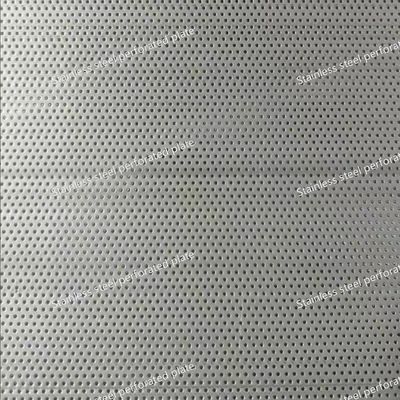

Микроперфорированный листок из нержавеющей стали диаметром отверстия 0,1 - 10,0 мм

| Место происхождения | Китай |

|---|---|

| Фирменное наименование | TISCO |

| Сертификация | ISO |

| Номер модели | 304 316L 430 410S. и др. |

| Количество мин заказа | 500 кг |

| Цена | 2100 - 3200 USD/Ton |

| Упаковывая детали | стандартная упаковка для экспорта |

| Время доставки | 5 - 12 дней в зависимости от количества |

| Условия оплаты | T/T, Western Union, L/C |

| Поставка способности | 10 тонн в неделю |

Свяжитесь я бесплатно образцы и талоны.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Если вы имеете любую заботу, то мы предусматриваем 24-часовую интерактивную справку.

xПодробная информация о продукте

| Продукты | Микроперфорированный лист из нержавеющей стали | Уровень | 304 201 316L 430 410S. и др. |

|---|---|---|---|

| Диаметр отверстия | 0.1 - 10.0mm | Размер | 1000*2000 мм 1219*2438 мм 1500*3000 мм |

| Толщина | 0.3 - 3,0 мм | Тип | холодно прокачанные |

| Поверхность | 2B | Применение | Промышленный |

| Упаковка | Деревянные поддоны | ||

| Выделить | Микроперфорированный листок из нержавеющей стали,перфорированный листок из нержавеющей стали 0 |

||

Характер продукции

Микроперфорированный листок из нержавеющей стали диаметром отверстия 0,1 - 10,0 мм

Спецификация продукции:

| Наименование продукта | Перфорированный лист из нержавеющей стали |

| Уровень | 201 304L 304 309S 310S 321 317L 316L 316Ti 2205 2507 904L 254SMO 409L 436 441. и т.д. |

| Форма отверстия | Алмаз, круглый, квадратный, шестиугольный |

| Размер сетки | 1000*2000мм, 1200*2400мм, 1250мм*2500мм, по заказу |

| Толщина вешалки | 0.3 мм-10 мм |

| Размер отверстия | Диаметр 0,1 - 10,0 мм |

| Техника | Перфорированные |

| Применение | Офисные потолки, охрана зданий, внутреннее оформление |

1. Обзор продукции

Наша стальная микропорная сетка - это высокоточное изделие, предназначенное для широкого спектра применений.,и SUS316L, обеспечивая отличную коррозионную стойкость, высокотемпературную стойкость и долговечность.

2. Особенности продукта

2.1 Точные размеры пор

Размеры пор наших микропористых сетчатых пластинок можно точно контролировать, от 0,08 мм до 2 мм.Эта высокая точность позволяет эффективное разделение и фильтрацию в различных промышленных процессахЭто может быть фильтрация мелких частиц в фармацевтической промышленности или разделение различных веществ в химической инженерии.наши сетчатые пластины могут соответствовать строгим требованиям точной фильтрации.

2.2 Единообразное распределение пор

Поры равномерно распределены по поверхности сетчатой пластины. Это равномерное распределение обеспечивает постоянную производительность по всей пластине, обеспечивая стабильную эффективность фильтрации и скорость потока.Независимо от того, где жидкость или газ проходит через сетку, он может достичь того же высококачественного эффекта разделения.

2.3 Гладкая поверхность и отверстия в стенах

Поверхность сетки и стены отверстия гладкие, что не только уменьшает сопротивление во время процесса прохождения жидкости или газа, улучшая скорость потока,но также облегчает очистку сеткиВ приложениях, где гигиена имеет решающее значение, таких как пищевая и напитковая промышленность, гладкая поверхность может предотвратить адгезию примесей и бактерий, обеспечивая качество и безопасность продукции.

2.4 Высокая прочность и долговечность

Изготовленные из высококачественной нержавеющей стали, наши микропористые сетки обладают высокой механической прочностью.сохранение их структурной целостности в течение длительного времениЭта высокая прочность и долговечность делают их подходящими для использования в суровых промышленных условиях.

3Производственный процесс

Мы используем передовые технологии производства, такие как лазерное ударение, химическое гравирование и электроформирование, для производства микропористых сетчатых пластин.

3.1 Лазерное перфорирование

Лазерный удар - это очень точный метод. высокоэнергетический лазерный луч может быстро расплавить и испарить материал из нержавеющей стали в назначенных местах,создание отверстий с точными диаметрами и гладкими краямиЭтот метод подходит для изготовления сетчатых пластин с небольшими размерами пор и высокой точностью.

3.2 Химическое гравирование

В процессе химического выгравирования на нержавеющую стальную пластину наносится химически устойчивая маска в соответствии с разработанным узором.Немаскированные участки постепенно вырисовываются.Химическое гравирование может производить сложные порические узоры и подходит для массового производства.

3.3 Электроформация

Электроформация включает в себя отложение ионов металла на узористый мандрел в электролитической ванне.оставляя за собой микропористую сетку с точной формой и высококачественной поверхностьюЭтот метод часто используется для изготовления сетчатых пластин с чрезвычайно тонкими структурами пор.

4. Приложения

4.1 Фильтрация в фармацевтической и пищевой промышленности

В фармацевтической промышленности наши микропористые сетчатые пластины используются для фильтрации лекарств, сырья и растворителей для обеспечения чистоты продукта.они наносятся на фильтрующие напитки, такие как пиво и фруктовые соки, а также в производстве молочных продуктов для удаления примесей и обеспечения безопасности пищевых продуктов.

4.2 Фильтрация с высокой точностью в химической технике

Для химических реакций и процессов разделения наши сетчатые пластины могут эффективно фильтровать твердые частицы, катализаторы и примеси в химических жидкостях,повышение эффективности и качества химического производстваОни также используются в фильтрации промышленных сточных вод и очистке отработавших газов для удовлетворения требований охраны окружающей среды.

4.3 Производство электроники и полупроводников

В электронной и полупроводниковой промышленности микропористые сетчатые пластины используются для таких применений, как очистка пластин, химико-механическая полировка, фильтрация суспензии,и газофазные процессы отложенияИх высокоточные размеры пор и гладкие поверхности могут удовлетворять строгим требованиям этих высокотехнологичных производственных процессов.

4.4 Автомобильная и аэрокосмическая промышленность

В автомобильной промышленности они могут использоваться в топливных фильтрах, фильтрах масла и фильтрах воздуха для повышения производительности и надежности двигателей.они применяются в системах топлива для самолетов, гидравлические системы и системы контроля окружающей среды для обеспечения безопасной эксплуатации воздушных судов.

5Спецификация продукта

5.1 Материал

- SUS304: предлагает хорошую коррозионную стойкость в общих условиях, с химическим составом, включающим хром (Cr) 18 - 20%, никель (Ni) 8 - 10,5%, и небольшое количество углерода (C), марганца (Mn),Кремний (Si), фосфор (P) и серка (S).

- SUS316: содержит молибден (Mo) 2 - 3% в дополнение к элементам SUS304, обеспечивая повышенную коррозионную стойкость, особенно в среде, содержащей хлорид.

- SUS316L: низкоуглеродный вариант SUS316, с содержанием углерода ≤ 0,03%, что еще больше улучшает его коррозионную стойкость при сварке.

5.2 Размеры пор

- Размеры пор, доступные в диапазоне от 0,08 мм до 2 мм. Мы также можем предоставить индивидуальные размеры пор в соответствии с конкретными требованиями клиентов.

5.3 Толщина пластины

Толщина сетчатых плит обычно варьируется от 0,1 мм до 3 мм. Тоньшие плите подходят для применений, требующих высокоточной фильтрации с небольшими размерами пор,в то время как более толстые пластины могут выдерживать более высокие дифференциальные давления.

5.4 Размеры плит

Стандартные размеры плат доступны в 1000 мм × 2000 мм и 1219 мм × 2438 мм. Однако мы также можем производить нестандартные размеры в соответствии с заказами клиентов для удовлетворения различных потребностей проекта.

6Контроль качества

У нас есть строгая система контроля качества, чтобы гарантировать, что каждая микропорная сетка соответствует самым высоким стандартам качества.

6.1 Проверка сырья

Все поступающие материалы из нержавеющей стали тщательно проверяются на предмет их химического состава, механических свойств и качества поверхности.В производстве используются только материалы, прошедшие проверку.

6.2 Процессуальная инспекция

Во время производственного процесса проводятся регулярные проверки для контроля размера пор, распределения пор и качества поверхности сетчатых пластинок.такие как оптические микроскопы, сканирующие электронные микроскопы и координатные измерительные машины, используются для обеспечения высокой точности производства.

6.3 Окончательные испытания продукции

Перед упаковкой каждая готовая сетка проходит серию комплексных испытаний, включая испытания на давление, эффективность фильтрации и коррозионность.Только продукты, прошедшие все эти испытания, могут покинуть завод..

7Упаковка и доставка

7.1 Упаковка

Наши микропористые сетки тщательно упакованы, чтобы не повредить их во время транспортировки.Деревянный ящик дополнительно закреплен пеной, чтобы обеспечить сохранность продукта во время длительного перевозки..

7.2 Доставка

Мы сотрудничаем с надежными логистическими партнерами для обеспечения своевременной доставки. В зависимости от местоположения клиента и количества заказа, мы можем выбрать наиболее подходящий способ транспортировки,например, морская перевозкаМы также предоставим номера отслеживания клиентам, чтобы они могли контролировать состояние доставки своих заказов в любое время.

![]()

![]()

![]()

![]()

Порекомендованные продукты