Todos os Produtos

-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

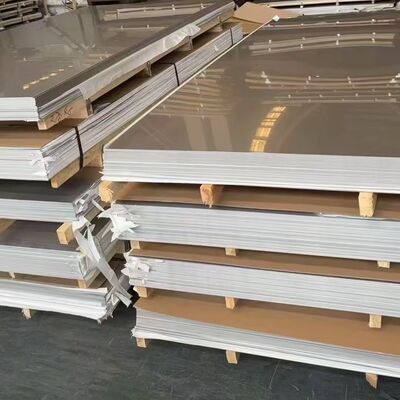

Chapa de aço inoxidável 416 laminada a frio e laminada a quente - Liga magnética e tratável termicamente para peças de precisão

| Lugar de origem | China |

|---|---|

| Marca | BAOSTEEL TISCO |

| Certificação | ISO |

| Número do modelo | 416 |

| Quantidade de ordem mínima | 50 kgs |

| Preço | 1.8-2.5USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 20ton por semana |

Detalhes do produto

| produtos | placa de aço inoxidável | Nota | 416 |

|---|---|---|---|

| Grossura | 0,5-50,0 mm | Tecnologia | laminado a frio, laminado a quente, forjado |

| Largura | 1000mm 1219mm 1500mm ou costumes como o pedido | Superfície | 2B NÃO.1 |

| Padrão | RUÍDO DO EN DE ASTM GB JIS | Quantidade mínima | 1 tonelada |

| Destacar | 416 Chapa de chapas de aço inoxidável,folhas de aço inoxidável magnético,Chapa de aço inoxidável tratável termicamente |

||

Descrição de produto

Folha de chapa de aço inoxidável laminada a frio e laminada a quente

Especificações das chapas de aço inoxidável

| Nome | 416 Placas de aço inoxidável |

| A nossa nota |

Série 200: 201 202 Série 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Série 400: 409L410,410S,415,416,420,430,431436 litros.439,441,443,444,445,446 Super aço inoxidável: 904L,926254SMO, 654SMO, 15-5PH, 17-4PH, 17-7PH, etc. Liga de níquel: C276, C22, G35, Liga X, Monel 400, K500, Inconel 600,601,617,625,718Incoloy 800,800H,800HT,825etc. |

| Técnica | Enrolados a quente, enrolados a frio, forjados |

| Padrão | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc. |

| Espessura | 0.1 80 mm |

| Faixa de largura | 10 mm 2000 mm |

| Duração | Personalizado |

| Acaba. | 2B, BA, não.4, 8k, escovado, linha do cabelo, revestimento PVD, arejado |

| Serviço | Corte a laser, dobra |

| Amostra | Disponível |

Placas e chapas de aço inoxidável laminadas a frio e laminadas a quente 416

Visão geral do produto

O aço inoxidável 416 é uma liga inoxidável martensítica, de usinagem livre, conhecida por sua excepcional usinagem, propriedades magnéticas e capacidade de ser tratada termicamente para aumentar a resistência.Disponível em rolos a frio e a quente, este material versátil serve como a espinha dorsal para componentes de alta precisão nos setores automotivo, aeroespacial, controle de fluidos, instrumentação e máquinas industriais.

O principal diferencial do aço inoxidável 416 reside no seu teor de enxofre controlado (≥ 0,15%),que melhora significativamente o comportamento de quebra de aspas durante a usinagem, tornando-o o aço inoxidável mais usinável da família martensíticaQuer seja necessária a tolerância apertada e o acabamento suave da chapa laminada a frio ou a robustez rentável da chapa laminada a quente,416 oferece um desempenho consistente para aplicações mecânicas exigentes.

Crucialmente, o 416 é magnético e tratável térmicamente, permitindo endurecimento a 25°45 HRC, ideal para eixos resistentes ao desgaste, engrenagens, hastes de válvulas,e elementos de fixação em que a estabilidade dimensional e a integridade da superfície são críticas.

Nota: Devido às limitações de soldabilidade induzidas pelo enxofre e à resistência moderada à corrosão, o 416 não é recomendado para estruturas soldadas ou ambientes agressivos (por exemplo, marinhos, ácidos,ou com elevado teor de cloreto)Para tais casos, considerar 316L ou 17-4PH.

Rolo frio versus laminado a quente: diferenças fundamentais

| Características | Outros, de aço inoxidável | Outros, de aço inoxidável |

|---|---|---|

| Revestimento de superfície | Suave, uniforme (Ra 0,4 ∼1,0 μm); frequentemente 2B/BA | Escaladas, mais ásperas; podem requerer decapagem |

| Tolerância dimensional | Apertado (normalmente ± 0,05 mm) | De espessura igual ou superior a ± 1% |

| Planosidade | Excelente. | Moderado (pode apresentar ligeira curvatura) |

| Força mecânica | Maior (devido ao endurecimento por tensão) | Inferior (estrutura anelada) |

| Faixa de espessura típica | 0.5 mm ️ 6.0 mm | 3.0 mm 50.0+ mm |

| Melhor para | Partes de precisão, usinagem CNC, componentes finos | Partes de estruturas, forjadas, peças pesadas |

Ambas as formas são totalmente tratáveis térmicamente e têm a mesma composição química em conformidade com a norma ASTM A276/A240.

Composição química (AISI 416 / UNS S41600)

| Elementos | Teor (%) |

|---|---|

| Carbono (C) | ≤ 015 |

| Manganês (Mn) | ≤ 100 |

| Fósforo (P) | ≤ 0040 |

| Enxofre (S) | ≥ 0,15 |

| Silício (Si) | ≤ 100 |

| Cromo (Cr) | 12.0 ¢ 14.0 |

| Níquel (Ni) | ≤ 060 |

| Ferro (Fe) | Balanço |

O elevado teor de enxofre permite uma superior maquinabilidade, mas reduz a ductilidade e a soldabilidade.

Comparação de propriedades mecânicas

| Condição | Resistência à tração | Força de rendimento | Extensão | Dureza (HB) |

|---|---|---|---|---|

| Fabrico a partir de matérias têxteis | 585 ∼ 760 MPa | 310 ∼ 450 MPa | 1822% | 190 ¢ 220 |

| Fabrico a partir de matérias têxteis | 515-725 MPa | 275 ∼415 MPa | 2025% | ≤183 |

| Tratados termicamente (H&T) | Até 1000 MPa | Até 850 MPa | 1015% | 25°45 HRC |

Tratamento térmico: austenitização a 980°C 1.010°C → apagamento a óleo → temperamento a 150°C 650.

Propriedades físicas e térmicas

| Imóveis | Valor |

|---|---|

| Densidade | 70,74 g/cm3 |

| Área de fusão | 1,450 ∼1,510°C (2,642 ∼2,750°F) |

| Conductividade térmica @ 100°C | 24.9 W/m·K |

| Calor específico | 460 J/kg·K |

| Coeficiente de expansão térmica | 10.0 μm/m·°C (20°C-100°C) |

| Magnético? | Sim ferromagnético |

A sua natureza magnética permite a sua utilização em sensores, solenoides e atuadores eletromagnéticos, ao contrário dos tipos não magnéticos da série 300.

Vantagem de maquinaria

O aço inoxidável 416 oferece uma maquinariabilidade de 85% em relação ao aço carbono B1112, superando em muito as qualidades austeníticas comuns:

| Grau | Máquinabilidade relativa | Desgaste de ferramentas versus 304 |

|---|---|---|

| 416 | 85% | 40% a 50% menos |

| 303 | 78% | 30% menos |

| 304 | 45% | Linha de base |

| 316 | 40% | Mais alto |

Os benefícios incluem:

- Velocidades de corte mais rápidas

- Consumo de energia reduzido

- Finalização superficial superior de peças viradas/moídas

- Extensão da vida útil do inserto em produção em grande volume

Aplicações típicas por forma

✅ Folha 416 laminada a frio (0,5 ∼6,0 mm)

- Outros aparelhos de ar condicionado

- Caixas de instrumentos

- Aparelhos para sensores automotivos

- Outros aparelhos de engrenagem de precisão

- Outros aparelhos de televisão e aparelhos de rádio

✅ Placas laminadas a quente de 416 mm (350+ mm)

- Outros aparelhos de ar condicionado

- Materiais de forja para acoplamentos

- Base de jig e de fixação

- Máquinas de secar ou de limpar

- Flancas, obtidas por mecanização

Perfil de resistência à corrosão

Resiste:

- Oxidação atmosférica (urbana/industrial)

- Exposição à água doce

- Ácidos orgânicos leves (a curto prazo)

- Gases secos e vapor

Evitar em:

- Água salgada ou ambientes costeiros

- Serviço de ácido clorídrico/sulfúrico

- Fluidos de processo ricos em cloreto

- Outros aparelhos de ar condicionado

A passivação ou o eletrolixo podem melhorar a camada de óxido superficial e melhorar o desempenho de corrosão leve.

Especificações disponíveis

| Parâmetro | Opções |

|---|---|

| Formulários | Folhas (≤ 6 mm), chapas (> 6 mm) |

| Processos | laminados a frio, laminados a quente (disponíveis em decapados e descascados) |

| Faixa de espessura | 0.5 mm ️ 50,0 mm |

| Largura/Longo | Até 1500 mm × 6000 mm (disponível para corte sob medida) |

| Revestimento de superfície | 2B, BA, não.1, HRAP (a quente, aquecido e em conserva) |

| Temperatura | Recheado (padrão), pré-endurecido (a pedido) |

| Normas | ASTM A240, ASTM A276, AISI 416, UNS S41600, JIS SUS416, EN 1.4009 |

| Certificações | Relatório de ensaio no moinho (EN 10204 3.1), opções compatíveis com RoHS, REACH, DFARS |

Orientações para o tratamento térmico

| Passo | Temperatura | Método de arrefecimento | Objetivo |

|---|---|---|---|

| Anilhamento | 815 ≈ 900°C | Ar fresco | Aquecimento para usinagem/formagem |

| Endurecimento | 980 ∼ 1.010°C | Extintor de óleo | Alcançar a estrutura martensítica completa |

| Temperamento | 150°C a 650°C | Ar fresco | Aliviar o estresse; ajustar a dureza |

Evitar a utilização prolongada a temperaturas superiores a 425 °C para evitar a fragilidade do temperamento.

Por que escolher o nosso aço inoxidável 416?

✅ Capacidade de processamento duplo: armazenar formas laminadas a frio e laminadas a quente para fornecimento flexível.

✅ Controle de qualidade de precisão: testes por ultra-som, inspeção de superfície e validação completa da química.

✅ Disponibilidade global: Armazéns na América do Norte, UE e Ásia.

✅ Apoio de engenharia: seleção de materiais, colaboração no tratamento térmico e feedback DFM.

✅ Sustentável: totalmente reciclável; > 90% de conteúdo reciclado possível.

✅ Controle de qualidade de precisão: testes por ultra-som, inspeção de superfície e validação completa da química.

✅ Disponibilidade global: Armazéns na América do Norte, UE e Ásia.

✅ Apoio de engenharia: seleção de materiais, colaboração no tratamento térmico e feedback DFM.

✅ Sustentável: totalmente reciclável; > 90% de conteúdo reciclado possível.

- Chapas de aço inoxidável laminadas a frio 416

- Placas de aço inoxidável laminadas a quente 416

- Aço inoxidável magnético tratável termicamente

- Material de peças de precisão AISI 416

- De aço inoxidável

- Placas SUS416 para hastes de válvula

- 416 aço inoxidável para sensores automotivos

- ASTM A240 416 fornecedor laminado a frio

Informações de encomenda

- Quantidade mínima de encomenda: 50 kg

- Prazo de entrega: 3-7 dias (tamanhos de estoque); 2-3 semanas (por customizado)

- Embalagem: papel VCI, caixas de madeira, fechadas por barreira de umidade

- Exemplos: Disponíveis para qualificação

Entre em contato com a nossa equipa de vendas técnicas para desenhos CAD, otimização de nesting ou certificação específica de lote.

Conclusão

Se você precisa da precisão dimensional do laminado a frio 416 para componentes de micro-válvulas ou o robusto estoque em branco do laminado a quente 416 para eixos pesados, este magnético,A liga tratável termicamente oferece uma maquinaria incomparável e versatilidade mecânicaAo selecionar o processo de laminação adequado para a sua aplicação, otimizará tanto o desempenho como a eficiência de custos, sem comprometer a fiabilidade.

Para peças de engenharia de precisão não soldadas em ambientes amenos, o aço inoxidável 416 continua a ser o padrão ouro para o design orientado para a maquinabilidade.

Produtos recomendados