-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

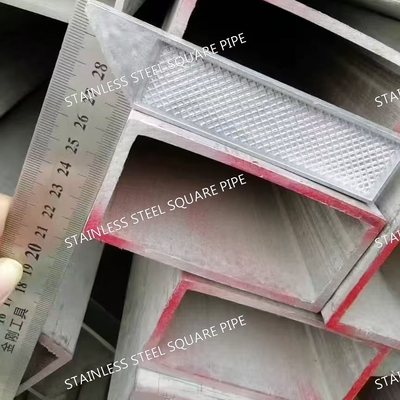

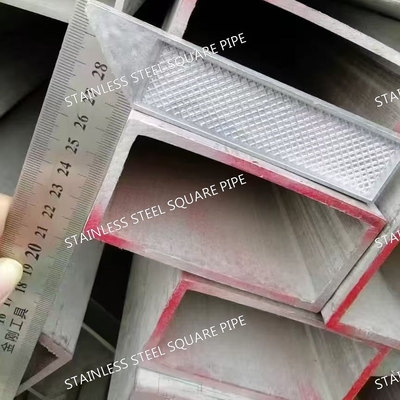

Tubo quadrado de aço inoxidável 316L 30x30mm 3mm

| Lugar de origem | China |

|---|---|

| Marca | DELTA |

| Certificação | ISO |

| Número do modelo | 304 316L 310S 2205 |

| Quantidade de ordem mínima | 500 kg |

| Preço | 5-10 USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias em função da quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 3 toneladas por semana |

Contacte-me para amostras grátis e vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

x| Produtos | Tubo quadrado de aço inoxidável | Grau | 304 316L 310S 321 2205 |

|---|---|---|---|

| Diâmetro | DN10 - DN400 | Comprimento | 6m ou corte por encomenda de qualquer comprimento |

| Padrão | ASTM EN | Serviço | Cortar |

| Porto de carga | Porto de Xangai | Espessura | 4.0 - 50.0 mm |

| Destacar | Tubo quadrado de aço inoxidável 316L,Tubos de qualidade marinha de 30x30 mm,Tubo de aço inoxidável de espessura de 3 mm |

||

| Atributo | Valor |

|---|---|

| Produtos | Tubo quadrado de aço inoxidável |

| Grau | 304 316L 310S 321 2205 |

| Diâmetro | DN10 - DN400 |

| Duração | 6m ou corte por encomenda de qualquer comprimento |

| Padrão | ASTM EN |

| Serviço | Cortar |

| Porto de carga | Porto de Xangai |

| Espessura | 4.0 - 50.0 mm |

Tubos quadrados de aço inoxidável 316LSão uma variante de baixo carbono de aço inoxidável 316, reconhecida pela sua excepcional resistência à corrosão, especialmente em ambientes agressivos como a água salgada e exposições químicas.A sua secção quadrada acrescenta estabilidade estrutural, tornando-os indispensáveis para aplicações industriais e arquitetónicas exigentes.

Os tubos quadrados de aço inoxidável 316L são componentes ocos e de forma quadrada fabricados a partir de liga 316L, um aço inoxidável austenítico contendo molibdênio.que minimiza a precipitação de carburo durante a soldagem, essencial para manter a resistência à corrosão nas estruturas soltasEsta liga proporciona força, formabilidade e durabilidade, superando o padrão 304 em condições adversas.

A química precisa do 316L garante as suas propriedades únicas:

| Elementos | Intervalo de conteúdo (%) | Função |

|---|---|---|

| Cromo (Cr) | 16.0-18.0 | Forma uma camada de óxido passivo, resistente à corrosão |

| Níquel (Ni) | 10.0-14.0 | Melhora a estrutura austenítica, melhorando a ductilidade e resistência |

| Molibdênio (Mo) | 2.0-3.0 | Aumenta a resistência à corrosão por furos e fendas (por exemplo, em água salgada) |

| Carbono (C) | ≤ 0.03 | Baixo teor de carbono impede a formação de carburo durante a soldagem |

| Manganês (Mn) | ≤ 2.0 | Auxilia na desoxidação e reforça a liga |

| Silício (Si) | ≤ 1.0 | Melhora a resistência à oxidação a altas temperaturas |

| Fósforo (P) | ≤ 0.045 | Controlados para evitar a fragilidade |

| Enxofre (S) | ≤ 0.03 | Minimizado para melhorar a soldabilidade |

316L tubos quadrados equilíbrio resistência e flexibilidade:

| Imóveis | Valor (típico) | Norma de ensaio |

|---|---|---|

| Resistência à tração | 485-620 MPa | ASTM E8 / EN 10002-1 |

| Força do rendimento (0,2% de compensação) | ≥ 170 MPa | ASTM E8 / EN 10002-1 |

| Elongamento (em 50 mm) | ≥ 40% | ASTM E8 / EN 10002-1 |

| Dureza (Brinell) | ≤ 217 HB | ASTM E10 / EN ISO 6506-1 |

| Modulo de Elasticidade | ~ 193 GPa | - |

| Densidade | 80,0 g/cm3 | - |

- Comprimento do lado:10 mm a 300 mm (por exemplo, 25 × 25 mm, 60 × 60 mm, 150 × 150 mm)

- Espessura da parede:0.8 mm a 12 mm (paredes mais espessas para utilização sob alta pressão ou em cargas pesadas)

- Duração:Padrão 6m; personalizável até 12m para projetos de grande escala

- Acaba:

- Finalização de moagem (2B): lisa, para utilização industrial

- Polido (BA/espelho): Refletor, para aplicações decorativas

- Pintado: textura opaca, comum nos acabamentos marítimos ou arquitetónicos

| Padrão | Órgão de emissão | Área de aplicação |

|---|---|---|

| ASTM A554 | ASTM Internacional | Tubos mecânicos soldados de aço inoxidável |

| EN 10217-7 | Comissão Europeia | Tubos soldados para pressão (aço inoxidável) |

| JIS G3446 | Normas Industriais Japonesas | Tubos quadrados de aço inoxidável |

| GB/T 12771 | Padrão Nacional da China | Tubos de aço inoxidável soldados |

Os tubos quadrados de 316L se destacam em ambientes onde a resistência à corrosão não é negociável:

- Engenharia Marítima:Barrancos, suportes de casco, plataformas offshore (resistentes à água salgada)

- Processamento químico:Tubos, estruturas de recipientes de reação e componentes dos tanques de armazenamento (resistentes a ácidos/alcalinos)

- Equipamento médico:Estruturas de ferramentas cirúrgicas, unidades de esterilização (higiénicas e resistentes à ferrugem)

- Alimentos e Bebidas:Sistemas de transportadores, equipamento de fabricação de cerveja (fácil de limpar, sem risco de contaminação)

- Arquitetura costeira:Corrimãos, fachadas e esculturas exteriores (resistentes ao vapor de mar)

- Petróleo e Gás:Tubos de poço, estruturas de plataformas offshore (toleram fluidos de perfuração agressivos)

- Resistência à corrosão superior:Supera o 304 em ambientes ricos em cloretos (por exemplo, água do mar, sais desglaçantes) devido ao molibdênio

- Soldabilidade:Baixo teor de carbono reduz a precipitação de carburo, garantindo que as juntas soldadas mantenham a resistência à corrosão

- Estabilidade a altas temperaturas:Mantenha a resistência a temperaturas de até 800°C, adequado para aplicações a altas temperaturas

- Longevidade:Com manutenção mínima, a vida útil excede 50 anos na maioria dos ambientes

- Higiene:Superfície não porosa resistente ao crescimento bacteriano, ideal para uso alimentar/médico

| Grau | Diferença fundamental em relação ao 316L | Melhor para |

|---|---|---|

| 316 | Maior teor de carbono (0,08% no máximo) | Estruturas não soldados; melhor resistência à alta temperatura |

| 304L | Sem molibdênio; menor resistência à corrosão | Ambientes leves (por exemplo, canalização interna) |

| 317L | Maior molibdênio (3,0-4,0%); melhor resistência ao furamento | Ambientes químicos extremos ou com elevado teor de sal |

| 2205 | Duplex (ferrítico-austenítico); maior resistência | Sistemas industriais de alta pressão |

Os tubos quadrados de aço inoxidável de 316L destacam-se pela sua baixa composição de carbono, resistência à corrosão reforçada por molibdênio e estabilidade estrutural.e aplicações de alta umidade onde a durabilidade e a fiabilidade são críticasSeja em máquinas industriais ou arquitetura costeira, 316L oferece desempenho que equilibra força, longevidade e adaptabilidade.