모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

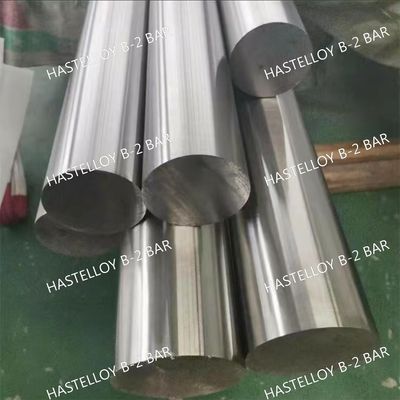

Hastelloy B-2 Round Bars Corrosion Resistant Nickel-Molybdenum Alloy With Various Sizes Available

제품 상세 정보

| 제품 | 하스텔로이 B-2 라운드바 | 등급 | 하스텔로이 B-2 |

|---|---|---|---|

| 지름 | 10 - 350 밀리미터 | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 밝고 검습니다 |

| 강조하다 | Hastelloy B-2 round bars,corrosion resistant nickel molybdenum alloy,Hastelloy B-2 bars various sizes |

||

제품 설명

Hastelloy B-2 Round Bars Corrosion Resistant Nickel-Molybdenum Alloy With Various Sizes Available

More Specification Informations

| Products Name | Hastelloy B-2 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy B-2 Round Bars: Corrosion Resistant Nickel-Molybdenum Alloy With Various Sizes Available

In the realm of high-performance alloys, Hastelloy B-2 round bars stand out as a premier solution for industries demanding exceptional corrosion resistance, high-temperature stability, and structural integrity. Composed primarily of nickel (minimum 62%) and molybdenum (26-30%), this nickel-molybdenum alloy is engineered to withstand some of the harshest operating environments, making it a top choice for chemical processing, oil and gas, pharmaceutical, and marine applications. Unlike conventional alloys that degrade under aggressive media such as hydrochloric acid, sulfuric acid, and organic halides, Hastelloy B-2 maintains its mechanical strength and corrosion resistance even at elevated temperatures (up to 1093°C/2000°F), ensuring long-term reliability and reduced maintenance costs for critical equipment.

Core Properties: Why Hastelloy B-2 Round Bars Excel

The superior performance of Hastelloy B-2 round bars stems from its unique chemical composition and microstructural stability. Molybdenum, the key alloying element, forms a dense protective oxide layer on the surface of the round bars when exposed to corrosive environments, preventing further oxidation and chemical attack. This layer is self-healing—if scratched or damaged, it rapidly reforms to restore protection, making the alloy ideal for applications where equipment is prone to mechanical wear or accidental impact. Additionally, Hastelloy B-2 exhibits low carbon content (maximum 0.02%), which minimizes carbide precipitation during welding or heat treatment. Carbide precipitation is a common issue in other alloys, as it leads to "sensitization" and increased susceptibility to intergranular corrosion. By avoiding this problem, Hastelloy B-2 round bars retain their corrosion resistance even after fabrication, ensuring consistent performance across the entire product lifecycle.

Mechanical properties further enhance the appeal of Hastelloy B-2 round bars. They offer a minimum tensile strength of 690 MPa (100 ksi) and a minimum yield strength of 310 MPa (45 ksi), with an elongation of 40% in the annealed state. These properties make the round bars suitable for load-bearing components in high-pressure systems, such as valves, fittings, and reactor internals. The alloy also maintains excellent ductility and toughness at cryogenic temperatures, expanding its utility to applications in liquefied natural gas (LNG) processing and aerospace.

Available Sizes and Specifications

Hastelloy B-2 round bars are manufactured in a wide range of sizes to meet the diverse needs of industrial projects, from small-scale precision components to large-diameter structural parts. The following table outlines the standard size range, along with corresponding dimensional tolerances, length options, and applicable standards. All round bars undergo rigorous quality control measures, including chemical composition analysis, mechanical testing (tensile, hardness), and non-destructive testing (ultrasonic inspection) to ensure compliance with international standards.

Note: Diameters larger than 300 mm are available on a custom order basis, with lead times varying based on production requirements. Surface finishes include hot-rolled (black) and cold-drawn (bright) options, with cold-drawn bars offering tighter tolerances and a smoother surface for precision applications.

Key Applications Across Industries

The versatility of Hastelloy B-2 round bars makes them indispensable in industries where corrosion resistance and high-temperature performance are non-negotiable.

- Chemical Processing: In chemical plants, Hastelloy B-2 round bars are used to fabricate heat exchangers, reaction vessels, and piping systems that handle concentrated hydrochloric acid, sulfuric acid, and acetic acid. Their resistance to pitting and crevice corrosion ensures that equipment remains operational even in acidic environments with high chloride concentrations.

- Oil and Gas: For upstream and downstream oil and gas operations, the round bars are employed in wellhead components, downhole tools, and offshore platforms. They withstand the corrosive effects of sour gas (containing hydrogen sulfide) and saltwater, reducing the risk of equipment failure in remote and harsh offshore locations.

- Pharmaceutical and Food Processing: The alloy’s high purity and resistance to organic solvents make it suitable for pharmaceutical reactors, food processing equipment, and clean-in-place (CIP) systems. It complies with FDA regulations for food contact materials, ensuring product safety and hygiene.

- Marine Engineering: In marine environments, Hastelloy B-2 round bars resist corrosion from seawater and salt spray, making them ideal for propeller shafts, seawater cooling systems, and offshore wind turbine components.

Quality Assurance and Customization

At our manufacturing facility, Hastelloy B-2 round bars are produced using state-of-the-art melting processes (vacuum induction melting and vacuum arc remelting) to ensure chemical homogeneity and minimize impurities. Each batch is accompanied by a material test report (MTR) that certifies compliance with customer specifications and international standards. We also offer value-added services, including precision machining (turning, milling, drilling), heat treatment (annealing, solution annealing), and surface coating (passivation, electropolishing) to meet the unique requirements of each application.

Whether you need small-diameter round bars for precision instruments or large-diameter bars for heavy-duty structural components, our team of engineers and metallurgists is committed to delivering high-quality products that exceed your expectations. With a global distribution network, we ensure timely delivery to projects worldwide, supported by responsive customer service to address any technical or logistical inquiries.

In summary, Hastelloy B-2 round bars represent the pinnacle of corrosion-resistant alloys, combining exceptional performance, versatility, and reliability. Their wide size range, compliance with international standards, and adaptability to diverse industries make them the preferred choice for engineers and procurement professionals seeking long-lasting solutions for challenging environments.

![]()

![]()

![]()

![]()

추천된 제품