모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

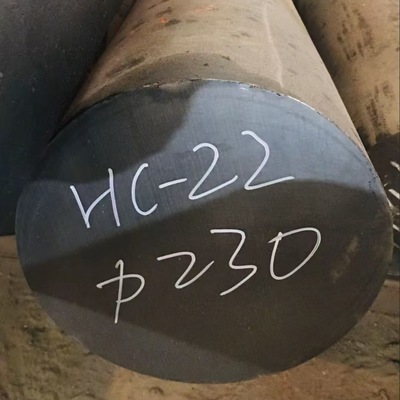

Hastelloy C22 Bar Hot Rolled & Forged Bars EN 2.4602 Alloy Bar Diameter 10 - 350mm Pass UT Test

제품 상세 정보

| 제품 | Hastelloy C-22 라운드 바 | 등급 | 하스텔로이 C22 |

|---|---|---|---|

| 지름 | 10 - 350 밀리미터 | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 밝고 검습니다 |

| 강조하다 | Hastelloy C22 alloy bar,EN 2.4602 forged bars,Nickel alloy bar with UT test |

||

제품 설명

Hastelloy C22 Bar Hot Rolled & Forged Bars EN 2.4602 Alloy Bar Diameter 10 - 350mm Pass UT Test

More Specification Informations

| Products Name | Hastelloy C22 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy C22 Bar Hot Rolled & Forged Bars EN 2.4602 Alloy Bar Diameter 10 - 350mm Pass UT Test

Hastelloy C22 (EN 2.4602) is a premium nickel-chromium-molybdenum-tungsten alloy renowned for its exceptional corrosion resistance, high-temperature stability, and mechanical strength—making its hot-rolled and forged round bars (with a diameter range of 10-350mm and UT test qualification) ideal for demanding industrial applications. Below is a comprehensive overview of this alloy bar, covering its chemical composition, mechanical properties, key characteristics, equivalent grades, and typical applications.

1. Chemical Composition

Hastelloy C22’s corrosion resistance and mechanical performance stem from its precisely balanced chemical composition, which adheres to international standards (e.g., ASTM B574, EN 10088-1). The typical composition (by weight percentage) is as follows:

| Element | Content Range (%) | Key Function |

|---|---|---|

| Nickel (Ni) | 56.0 min | Base metal; provides excellent ductility, toughness, and resistance to stress corrosion cracking |

| Chromium (Cr) | 20.0 - 22.5 | Enhances oxidation resistance (even at high temperatures) and resistance to pitting/crevice corrosion |

| Molybdenum (Mo) | 12.5 - 14.5 | Boosts resistance to reducing environments (e.g., acids) and prevents localized corrosion |

| Tungsten (W) | 2.5 - 3.5 | Complements molybdenum to improve corrosion resistance in harsh media (e.g., sulfuric acid) and enhances high-temperature strength |

| Iron (Fe) | 2.0 - 6.0 | Improves workability during hot rolling/forging and reduces alloy cost without compromising performance |

| Cobalt (Co) | 2.5 max | Controlled to minimize potential embrittlement in high-temperature services |

| Carbon (C) | 0.015 max | Low carbon content prevents carbide precipitation (a common cause of intergranular corrosion) during welding or heat treatment |

| Silicon (Si) | 0.08 max | Reduces oxide formation and improves castability/forgability |

| Manganese (Mn) | 0.5 max | Aids in deoxidation during manufacturing and enhances ductility |

| Phosphorus (P) | 0.02 max | Minimized to avoid brittleness and corrosion susceptibility |

| Sulfur (S) | 0.01 max | Strictly controlled to prevent hot cracking during welding and forging |

2. Mechanical Properties

The hot-rolled and forged Hastelloy C22 bars (diameter 10-350mm) exhibit excellent mechanical strength and ductility, even at elevated temperatures. Below are the typical mechanical properties (tested at room temperature, per ASTM B574):

| Property | Specification (Typical Value) | Test Standard |

|---|---|---|

| Tensile Strength (σb) | ≥ 690 MPa (100 ksi) | ASTM E8/E8M |

| Yield Strength (σ0.2) | ≥ 310 MPa (45 ksi) | ASTM E8/E8M |

| Elongation at Break (δ) | ≥ 40% | ASTM E8/E8M |

| Hardness (Brinell, HBW) | ≤ 210 | ASTM E10 |

| Impact Toughness (Charpy V-notch) | ≥ 100 J (74 ft-lb) at -196°C (-321°F) | ASTM A370/ASTM E23 |

Note: Mechanical properties can be adjusted via post-forging heat treatment (e.g., solution annealing at 1120-1170°C followed by rapid quenching) to optimize strength or ductility for specific applications.

3. Key Characteristics

Hastelloy C22 hot-rolled and forged bars stand out for their unique combination of properties, making them superior to many other nickel alloys:

-

Exceptional Corrosion Resistance:

It resists a wide range of aggressive media, including sulfuric acid, hydrochloric acid, acetic acid, seawater, and chloride-containing solutions. Unlike lower-grade alloys, it avoids pitting, crevice corrosion, and intergranular corrosion—even in harsh environments like chemical processing plants or offshore oil platforms. -

High-Temperature Stability:

The alloy maintains its mechanical strength and oxidation resistance at temperatures up to 1093°C (2000°F). It is resistant to “hot corrosion” (attack by molten salts or sulfur-rich gases), making it suitable for high-temperature applications like furnace components or gas turbine parts. -

Excellent Fabricability:

The hot-rolled and forged bars offer good ductility, enabling easy machining, welding (compatible with TIG/MIG welding processes), and forming (e.g., bending, flanging). Low carbon content eliminates the need for post-weld heat treatment to restore corrosion resistance. -

UT Test Qualification:

All bars (10-350mm diameter) pass Ultrasonic Testing (UT) per standards like ASTM A609 or EN 10228-3. This ensures the absence of internal defects (e.g., cracks, inclusions) that could compromise structural integrity in critical applications. -

Toughness at Cryogenic Temperatures:

Unlike many alloys that become brittle at low temperatures, Hastelloy C22 retains high impact toughness even at -196°C (-321°F), making it suitable for cryogenic equipment (e.g., liquid natural gas storage).

4. Equivalent Grades

Hastelloy C22 is recognized under various international standards and has equivalent grades across regions, ensuring consistency in performance and interchangeability:

| Standard Organization | Grade Designation | Common Name |

|---|---|---|

| ASTM (USA) | UNS N06022 | Hastelloy C22 |

| EN (Europe) | 2.4602 | Nickel Alloy 2.4602 |

| DIN (Germany) | NiCr22Mo9W | — |

| JIS (Japan) | NW 20602 | — |

| ISO | NiCr22Mo9W | — |

These grades share identical chemical and mechanical properties, so Hastelloy C22 bars (EN 2.4602) can be used as direct replacements for UNS N06022 or DIN NiCr22Mo9W in global projects.

5. Applications

Thanks to its versatile performance, hot-rolled and forged Hastelloy C22 bars (10-350mm diameter) are widely used in industries requiring corrosion resistance, high-temperature strength, or structural reliability. Typical applications include:

-

Chemical Processing:

Reactors, pressure vessels, heat exchangers, and piping for handling acids (sulfuric, hydrochloric), solvents, and corrosive intermediates. -

Oil & Gas Industry:

Downhole components (tubing, casings), offshore platform structures, and wellhead equipment—resistant to seawater and sour gas (H₂S). -

Pharmaceutical & Food Processing:

Equipment (mixing tanks, conveyor parts) that requires corrosion resistance to clean-in-place (CIP) solutions and compliance with hygiene standards (e.g., FDA). -

High-Temperature Equipment:

Furnace heating elements, gas turbine combustion chambers, and aerospace components—withstands elevated temperatures and oxidation. -

Environmental Engineering:

Wastewater treatment systems, flue gas desulfurization (FGD) units, and air pollution control equipment—resistant to acidic effluents.

![]()

![]()

![]()

![]()

추천된 제품