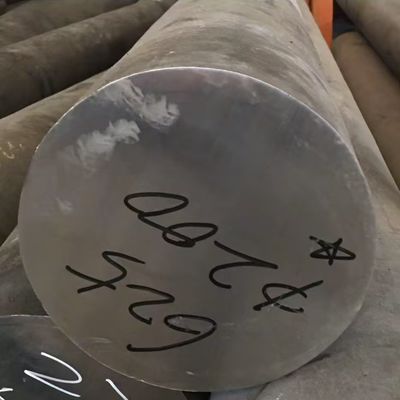

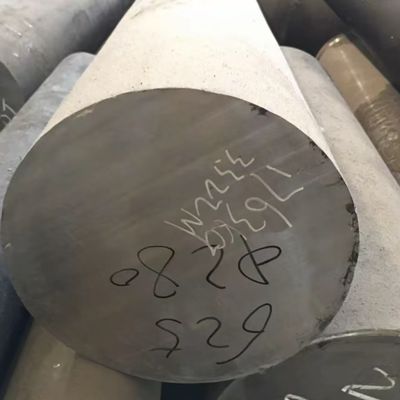

- ASTM B446 Inconel 625 Rod, 2-16" Diameter, Oil Drilling W.Nr. 2.4856 Nickel Alloy

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725

Incoloy series: 800 800H 825 925

Hastelloy series: B,B2,B3,C,C-276,C-4,C-22

Pure: Ni200, Ni201

|

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

Width

|

1~1500mm

|

|

Square bar

|

Size: 4*4-100*100mm

|

|

Length

|

2m, 5.8m, 6m, or as required.

|

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

For oil and gas drilling operations operating in extreme downhole environments—where corrosive brines, high temperatures up to 1093°C (2000°F), and extreme pressure test equipment durability—ASTM B446 Inconel 625 round rod (W.Nr. 2.4856, UNS N06625) stands as an uncompromising material solution. Available in 2-16" diameters, this nickel-chromium-molybdenum-niobium superalloy delivers the strength, corrosion resistance, and structural integrity required for critical drilling components, from downhole tools to wellhead equipment.

At the core of its performance is a meticulously engineered chemical composition that defines its superalloy properties. Composed of a minimum 58% nickel matrix—providing inherent resistance to chloride stress corrosion cracking—this alloy incorporates 20.0-23.0% chromium for oxidation resistance, 8.0-10.0% molybdenum for defense against reductive corrosion, and 3.15-4.15% niobium (including tantalum) for solid-solution strengthening . Trace elements are tightly controlled: carbon (≤0.10%), silicon (≤0.50%), phosphorus (≤0.015%), and sulfur (≤0.015%) to avoid grain boundary degradation and maintain weldability . This precise formulation eliminates the need for post-fabrication heat treatment while delivering exceptional mechanical performance.

The mechanical properties of this Inconel 625 rod are tailored to meet oil drilling’s rigorous demands. In the annealed condition—standard for most drilling applications—it achieves a minimum tensile strength of 760 MPa (110 ksi) and yield strength of 345 MPa (50 ksi), with elongation exceeding 30% for enhanced ductility during component forming . For high-stress applications like drill collars or heavy-duty valves, cold-worked variants push tensile strength to 1924 MPa (279 ksi) while retaining critical toughness . Notably, these properties remain consistent across temperature extremes, from cryogenic conditions to the searing heat of deepwell environments, ensuring reliable performance where conventional alloys fail.

Corrosion resistance is the alloy’s defining advantage for oil drilling. It excels in the most aggressive downhole chemistries: resisting pitting and crevice corrosion in chloride-rich brines, withstanding inorganic acids (including sulfuric and hydrochloric acids common in acidizing treatments), and enduring both oxidizing and reducing environments . Unlike carbon steels or even lesser nickel alloys, Inconel 625 (W.Nr. 2.4856) avoids stress corrosion cracking in sour gas wells, complying with NACE MR 0175 (ISO 15156-3) standards for hydrogen sulfide service . In seawater injection systems and offshore drilling platforms, it demonstrates near-immunity to marine corrosion, outperforming stainless steels by orders of magnitude .

Manufactured to ASTM B446 (and ASME SB446 for pressure-containing components), our Inconel 625 rods adhere to strict dimensional tolerances and quality controls. The 2-16" diameter range covers the most common sizes for drilling applications: 2-4" rods for precision downhole sensors, 6-10" for valve stems and actuator components, and 12-16" for heavy-duty drill string accessories . Each rod undergoes annealing at 1095°C (2000°F) followed by rapid cooling to optimize grain structure and corrosion resistance, with surface finishes available from mill scale to precision ground for tight-fit assemblies.

In oil drilling operations, this material translates to tangible value: extended service life for components exposed to abrasive drilling fluids, reduced downtime from corrosion-related failures, and compliance with strict industry safety standards. Typical applications include:

- Downhole tool mandrels and stabilizers

- Wellhead valve trim and choke components

- Subsea pipeline connectors and fasteners

- Acidizing equipment and pressure vessels

- Offshore platform structural supports

Beyond performance, our Inconel 625 rods support operational efficiency. Their excellent weldability—even without preheating or post-weld heat treatment—simplifies on-site modifications, while their non-magnetic properties make them ideal for use near logging tools . Each shipment includes full mill certification with chemical analysis, mechanical test results, and traceability documentation, ensuring compliance with API and ISO requirements.

Choosing the right alloy for drilling applications means balancing performance and practicality—and ASTM B446 Inconel 625 rod delivers on both fronts. Its unique combination of strength, corrosion resistance, and fabricability makes it the material of choice for operators who refuse to compromise on reliability in extreme environments. Whether for onshore shale wells, deepwater exploration, or sour gas production, our 2-16" diameter W.Nr. 2.4856 nickel alloy rods provide the durability needed to keep drilling operations running safely and efficiently.

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다![]()

![]()

![]()

![]()

![]()