-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

High Quality Monel 400 Round Bar Corrosion Resistant, HighStrength for Marine/Industrial Applications, Precision Machined

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 제품 | 모넬 400 둥근 바 | 등급 | 모넬 400 |

|---|---|---|---|

| 지름 | 10 - 350 밀리미터 | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 블랙, 브라이트 |

| 강조하다 | Monel 400 round bar corrosion resistant,Nickel alloy round bar high strength,Precision machined Monel 400 marine applications |

||

High Quality Monel 400 Round Bar Corrosion Resistant, HighStrength for Marine/Industrial Applications, Precision Machined

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

|

Package

|

Export standard package, bundled or be required.

The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

||

High Quality Monel 400 Round Bar Corrosion Resistant, High Strength for Marine/Industrial Applications, Precision Machined

Product Overview

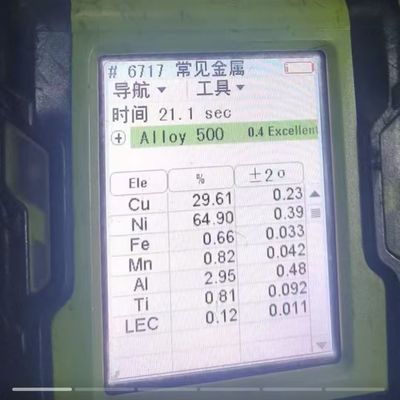

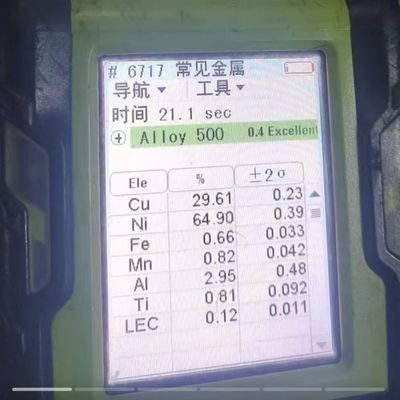

Our high-quality Monel 400 Round Bar is a premium nickel-copper alloy product designed for the most demanding marine and industrial applications. Manufactured to international standards such as ASTM B164 , this round bar offers exceptional corrosion resistance, high strength, and excellent machinability. Monel 400 (UNS N04400) is renowned for its superior performance in corrosive environments, making it an ideal choice for critical components in offshore, chemical processing, oil and gas, and marine engineering sectors.

Key Features and Benefits

-

Exceptional Corrosion Resistance: Monel 400 demonstrates outstanding resistance to a wide range of corrosive media. It performs excellently in seawater, salt solutions, hydrofluoric acid, sulfuric acid, phosphoric acid, and alkaline solutions . Its corrosion rate in flowing seawater is less than 0.025mm/year, outperforming many stainless steels and copper-based alloys in marine environments.

-

High Strength and Durability: This round bar provides excellent mechanical properties, with a typical tensile strength of ≥480 MPa, yield strength of ≥170 MPa, and elongation of ≥35% in the annealed condition . It maintains good strength and toughness from sub-zero temperatures up to about 540°C .

-

Precision Machined: Our Monel 400 round bars are precision machined to meet tight dimensional tolerances (e.g., h8, h9 grades for cold-drawn bars ), ensuring easy integration into your designs and reducing secondary machining requirements.

-

Excellent Fabricability: The material features a single-phase austenitic microstructure that allows for good cold and hot workability. It can be welded using common methods like TIG and MIG with appropriate filler materials (e.g., ENiCu-7) .

-

Long Service Life: Components made from our Monel 400 round bar offer extended service life in aggressive environments, reducing maintenance costs and downtime .

Technical Specifications

-

Material Grade: Monel 400 / UNS N04400 / NCu30-2-1 / 2.4360

-

Standard Specifications: ASTM B164, ASTM B865, ASME SB-164, SB-865, GB/T standards

-

Chemical Composition (Typical wt%):

-

Nickel (Ni): ≥ 63%

-

Copper (Cu): 28 - 34%

-

Iron (Fe): ≤ 2.5%

-

Manganese (Mn): ≤ 2.0%

-

Carbon (C): ≤ 0.3%

-

Silicon (Si): ≤ 0.5%

-

Sulfur (S): ≤ 0.024%

-

-

Physical Properties:

-

Density: 8.8 g/cm³

-

Melting Point: 1300-1350°C

-

-

Mechanical Properties (Annealed Condition):

-

Tensile Strength: ≥ 480 MPa

-

Yield Strength (0.2% Offset): ≥ 170 MPa

-

Elongation: ≥ 35%

-

Hardness: HB 150-200

-

-

Available Forms and Sizes:

-

Hot-rolled round bars: Diameter Φ8mm - Φ100mm

-

Cold-drawn/finished round bars: Diameter Φ2mm - Φ280mm

-

Forged round bars: Diameter Φ30mm - Φ350mm

-

Custom sizes and lengths available upon request

-

Applications

Our Monel 400 round bar is suitable for a wide range of critical applications, including:

-

Marine & Offshore: Pump shafts, propeller shafts, valve stems, fasteners, seawater piping systems, condenser tubes, desalination plant components .

-

Oil & Gas: Valve components, pump parts, downhole tools, piping components for corrosive oil and gas production environments .

-

Chemical Processing: Reactors, heat exchangers, vessels, piping, and fittings handling acids (especially HF and H₂SO₄), alkalis, and other corrosive chemicals .

-

Power Generation: Components in feedwater heaters, evaporators, and other equipment .

-

Other Industries: Aerospace (fuel system components ), pharmaceutical, and water treatment equipment.

Packaging and Quality Assurance

Every shipment of our Monel 400 round bar includes a complete Material Test Report (MTR) that certifies compliance with the specified standards, including chemical composition and mechanical properties . We employ strict quality control throughout the manufacturing process and use proper packaging (e.g., rust-preventive oil, VCI paper ) to ensure the product arrives in perfect condition.

Why Choose Our Monel 400 Round Bar?

-

Consistent High Quality: Sourced from reputable mills employing vacuum melting techniques (VIM/VAR) for high purity .

-

Technical Expertise: Our team provides expert guidance on material selection and fabrication techniques.

-

Reliable Supply: We maintain stock to meet your project timelines.

-

Competitive Pricing: We offer competitive pricing for high-quality material.

Contact Us Today

For more information on our high-quality Monel 400 round bars, pricing, or to discuss your specific requirements, please contact our sales team. We are ready to provide technical support and help you choose the right material for your application.