すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

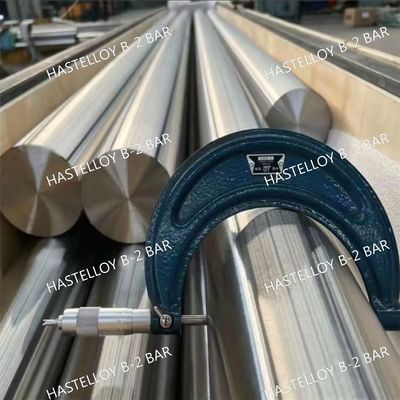

Hastelloy B-2 (UNS N10665) Round Bar Excellent Resistance for Industrial Applications

商品の詳細

| 製品 | ハステロイ B-2 丸棒 | 学年 | ハステロイB-2 |

|---|---|---|---|

| 直径 | 10 - 350mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | 明るい、黒い |

| ハイライト | Hastelloy B-2 round bar,UNS N10665 nickel alloy bar,industrial corrosion resistant round bar |

||

製品の説明

Hastelloy B-2 (UNS N10665) Round Bar Excellent Resistance for Industrial Applications

More Specification Informations

| Products Name | Hastelloy B-2 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy B-2 (UNS N10665) Round Bar Excellent Resistance for Industrial Applications

Hastelloy B-2 (UNS N10665) round bar is a premium nickel - molybdenum alloy product renowned for its exceptional resistance to severe corrosive environments, especially in reducing media. Its unique chemical composition and optimized mechanical properties make it a reliable choice for critical industrial applications where durability, corrosion resistance, and structural stability are non - negotiable. Whether in chemical processing, oil and gas, or pharmaceutical industries, this round bar delivers consistent performance, even under extreme temperatures and harsh chemical exposures.

1. Chemical Composition (Typical, % by Weight)

The carefully balanced chemical composition of Hastelloy B-2 (UNS N10665) is the foundation of its outstanding corrosion resistance and mechanical strength. The key elements and their typical weight percentages are as follows:

- Nickel (Ni): 65.0 - 70.0% (base element, providing excellent ductility and resistance to general corrosion)

- Molybdenum (Mo): 26.0 - 30.0% (the primary alloying element, enhancing resistance to pitting, crevice corrosion, and reducing acids like hydrochloric acid)

- Iron (Fe): ≤ 2.0% (improves thermal stability and processability without compromising corrosion resistance)

- Chromium (Cr): ≤ 1.0% (minimized to avoid precipitation of harmful phases in reducing environments)

- Carbon (C): ≤ 0.02% (low carbon content prevents carbide precipitation, which could lead to intergranular corrosion at high temperatures)

- Manganese (Mn): ≤ 1.0% (aids in casting and forming processes)

- Silicon (Si): ≤ 0.1% (reduces the risk of oxide formation and maintains alloy purity)

- Phosphorus (P): ≤ 0.04% (controlled to avoid brittleness)

- Sulfur (S): ≤ 0.03% (minimized to prevent corrosion and improve mechanical integrity)

2. Mechanical Properties (Typical Values, Annealed Condition)

Hastelloy B-2 (UNS N10665) round bar exhibits excellent mechanical properties, including high tensile strength, good ductility, and resistance to deformation under stress. The following are typical values for annealed round bars (tested at room temperature):

- Tensile Strength (σb): ≥ 690 MPa (100 ksi)

- Yield Strength (σ0.2): ≥ 310 MPa (45 ksi)

- Elongation (δ): ≥ 40% (in 50 mm gauge length, indicating excellent ductility for forming and fabrication)

- Hardness (Brinell Hardness, HB): ≤ 230 (annealed, ensuring ease of machining and welding)

- Impact Toughness (Charpy V - Notch): ≥ 100 J (at room temperature, demonstrating resistance to brittle fracture in low - temperature or high - stress environments)

At elevated temperatures (up to 540°C / 1000°F), the alloy retains most of its mechanical strength, making it suitable for high - temperature industrial processes.

3. Standards Compliance

Hastelloy B-2 (UNS N10665) round bar is manufactured in strict accordance with international and industry standards to ensure consistent quality and performance. Key compliance standards include:

- ASTM B335: Standard Specification for Nickel - Alloy Rod and Bar (the primary standard for nickel - molybdenum alloy bars, covering chemical composition, mechanical properties, and dimensional tolerances)

- ASME SB - 335: Boiler and Pressure Vessel Code (for applications in pressure vessels and boilers, ensuring safety and reliability under high - pressure conditions)

- UNS N10665: Unified Numbering System designation (globally recognized identifier for Hastelloy B-2 alloy)

- DIN 17750: German standard for nickel and nickel - alloy bars (compliant for European market requirements)

- ISO 9723: International Organization for Standardization standard for nickel - base alloy rod and bar (ensuring global compatibility in manufacturing and engineering)

4. Similar Grades

While Hastelloy B-2 (UNS N10665) is a unique alloy, there are several 相近牌号 (similar grades) with comparable properties, often used as alternatives in specific regions or applications. These include:

- Hastelloy B - 3 (UNS N10675): An improved version of Hastelloy B - 2, with better thermal stability and resistance to localized corrosion (ideal for high - temperature reducing environments where B - 2 may be prone to phase precipitation)

- Nickel 201 (UNS N02201): A pure nickel grade with good corrosion resistance in reducing media, but lower molybdenum content than B - 2 (suitable for less severe corrosive conditions)

- Alloy 625 (UNS N06625): A nickel - chromium - molybdenum alloy with excellent all - around corrosion resistance, though higher chromium content makes it more suitable for oxidizing environments (alternative for mixed oxidizing - reducing conditions)

- DIN 2.4617: German designation for nickel - molybdenum alloy, equivalent to Hastelloy B - 2 (used in European industrial applications)

5. Industrial Applications

Thanks to its exceptional resistance to reducing acids (such as hydrochloric acid, sulfuric acid in reducing conditions, and phosphoric acid) and high - temperature stability, Hastelloy B-2 (UNS N10665) round bar is widely used in the following critical industrial sectors:

- Chemical Processing: Used in reactors, heat exchangers, and piping systems for processing hydrochloric acid, acetic acid, and other corrosive chemicals. Its resistance to acid chloride solutions makes it ideal for vinyl chloride monomer (VCM) production.

- Oil and Gas: Applied in downhole tubulars, wellhead components, and offshore platforms, where it withstands corrosive fluids (e.g., sour gas, brines) and high - pressure conditions.

- Pharmaceutical and Food Processing: Utilized in equipment for manufacturing drugs, food additives, and beverages, as it is non - toxic and resistant to organic acids (e.g., citric acid, lactic acid).

- Wastewater Treatment: Used in pumps, valves, and clarifiers for treating industrial wastewater containing high concentrations of chlorides or acids, preventing corrosion and ensuring long - term equipment reliability.

- Aerospace and Defense: Employed in components for rocket engines and aircraft fuel systems, where it resists corrosion from jet fuel and high - temperature exhaust gases.

In all these applications, Hastelloy B-2 (UNS N10665) round bar stands out for its ability to maintain structural integrity and performance, even in the most demanding operational environments.

推薦されたプロダクト