すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

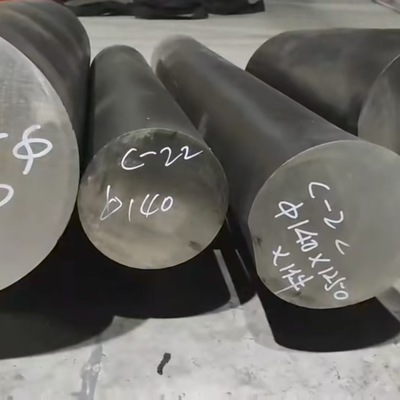

Premium Hastelloy C-22 Round Bar - Alloy 2.4602 Material, Excellent Weldability, Corrosion-Resistant for Oil/Gas

商品の詳細

| 製品 | ハステロイ C-22 丸棒 | 学年 | Hastelloy C22 |

|---|---|---|---|

| 直径 | 10 - 350mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | 明るい、黒い |

| ハイライト | Hastelloy C-22 round bar,Alloy 2.4602 corrosion-resistant bar,Nickel alloy oil gas weldable |

||

製品の説明

Hastelloy C-22 Round Bar (ASTM B574) Superior Pitting/Crevice Corrosion Resistance, High Strength & Durability

More Specification Informations

| Products Name | Hastelloy C22 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Premium Hastelloy C-22 Round Bar - Alloy 2.4602 Material, Excellent Weldability, Corrosion-Resistant for Oil/Gas

Product Overview

Our Hastelloy C-22 Round Bar stands as a top-tier solution for high-demand industrial applications, particularly in the oil and gas sector. Crafted from Alloy 2.4602 (the official UNS designation for Hastelloy C-22), this round bar delivers unmatched performance in harsh environments, combining exceptional corrosion resistance, superior weldability, and robust mechanical strength. Whether used in offshore drilling equipment, chemical processing pipelines, or refinery components, it ensures long-term reliability and minimizes maintenance costs—making it a preferred choice for engineers and procurement teams worldwide.

Core Material Advantages: Alloy 2.4602

Hastelloy C-22 (Alloy 2.4602) is a nickel-chromium-molybdenum-tungsten alloy engineered to excel in aggressive chemical and high-temperature conditions. Its unique composition offers:

- Broad-spectrum corrosion resistance: Resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in environments containing chlorides, sulfuric acid, hydrochloric acid, and mixed organic/inorganic acids—critical for oil and gas operations where exposure to salty seawater, sour gas (H₂S), and acidic process fluids is common.

- High-temperature stability: Maintains mechanical integrity at temperatures up to 1,093°C (2,000°F), making it suitable for downhole tools, heat exchangers, and furnace components in refineries.

- Impurity resistance: Low carbon content (<0.015%) prevents carbide precipitation during welding or heat treatment, eliminating the risk of intergranular corrosion—a common failure point in lesser alloys.

Excellent Weldability for Seamless Integration

One of the standout features of our Hastelloy C-22 Round Bar is its exceptional weldability, which simplifies fabrication and ensures strong, leak-free joints—essential for oil and gas infrastructure (e.g., pipelines, pressure vessels). Key welding benefits include:

- Compatible with all standard fusion welding processes, including TIG (GTAW), MIG (GMAW), and shielded metal arc welding (SMAW).

- Minimal pre-weld heating or post-weld heat treatment required, reducing production time and costs.

- Welded joints retain the same corrosion resistance and mechanical strength as the base material, avoiding weak points in critical systems.

- Our round bars are supplied with a smooth, defect-free surface (per ASTM B622 standards) to ensure consistent weld quality and reduce post-weld cleanup.

Oil & Gas Application Focus

The oil and gas industry demands materials that can withstand extreme pressures, temperatures, and corrosive media—and our Hastelloy C-22 Round Bar is purpose-built for these challenges. Typical applications include:

- Offshore drilling: Used in subsea wellheads, risers, and manifold components, where resistance to seawater corrosion and hydrogen sulfide (H₂S) is non-negotiable.

- Refining: Fabricated into heat exchanger tubes, reactor internals, and catalyst support grids, handling acidic crude oil processing and high-temperature distillation.

- Upstream production: Employed in downhole tools (e.g., drill collars, valves) and surface pipelines, enduring harsh downhole conditions (high pressure, sour gas) and surface exposure to chemicals.

- Gas processing: Used in amine sweetening units and natural gas dehydration systems, resisting corrosion from amine solvents and moisture.

Specifications & Quality Assurance

To meet the strict standards of the oil and gas industry, our Hastelloy C-22 Round Bar adheres to global specifications and undergoes rigorous quality testing:

- Dimensions: Diameters ranging from 6mm to 300mm (0.24” to 11.81”), with custom lengths available (up to 6 meters) to reduce waste and fabrication time.

- Standards compliance: Manufactured in accordance with ASTM B622 (standard for nickel-chromium-molybdenum-tungsten alloy rod and bar), ASME SB622, and EN 10095 (for European markets).

- Quality testing: Each batch undergoes:

- Chemical composition analysis (via X-ray fluorescence or optical emission spectroscopy) to verify Alloy 2.4602 purity.

- Mechanical testing (tensile strength, yield strength, elongation) to ensure compliance with industry requirements (minimum tensile strength: 690 MPa; minimum yield strength: 275 MPa).

- Non-destructive testing (NDT), including ultrasonic testing (UT) and magnetic particle inspection (MPI), to detect internal or surface defects.

Why Choose Our Hastelloy C-22 Round Bar?

- Guaranteed material authenticity: 100% traceability from raw material sourcing to final delivery, with certificates of analysis (CoA) provided for every order.

- Customization options: Available in annealed, solution-treated, or cold-worked conditions to match specific application requirements (e.g., cold-worked for higher strength in structural components).

- Global support: Our team of metallurgical engineers offers technical assistance for welding, fabrication, and application selection, ensuring you get the most out of your investment.

- Competitive lead times: With dedicated production lines and strategic inventory, we deliver orders within 2–4 weeks for standard sizes, minimizing project delays.

![]()

![]()

![]()

![]()

推薦されたプロダクト