すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

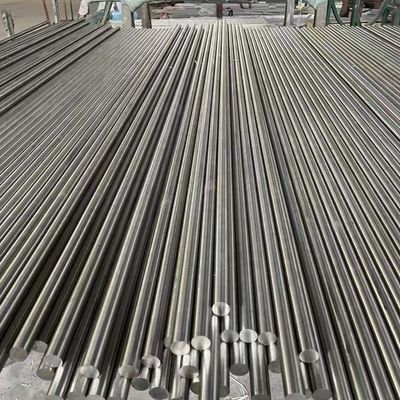

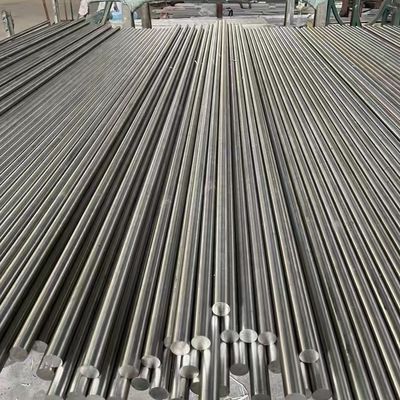

ASTM B446 Inconel 625 Round Bar, 1-12" Diameter, Aerospace UseAlloy UNS N06625 Bars

商品の詳細

| 製品 | Inconel 625の丸棒 | 学年 | インコネル625 |

|---|---|---|---|

| 直径 | 10 - 350mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | ブラック、ブライト |

| ハイライト | Inconel 625 round bar,ASTM B446 nickel alloy bar,aerospace Inconel 625 bars |

||

製品の説明

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

ASTM B446 Inconel 625 Round Bar, 1-12" Diameter, Aerospace UseAlloy UNS N06625 Bars

In the high-stakes aerospace industry, material reliability directly impacts flight safety and performance. Our ASTM B446-compliant Inconel 625 round bars (UNS N06625) are engineered to exceed the most rigorous demands of aircraft and spacecraft manufacturing, offering unmatched strength, corrosion resistance, and thermal stability across a 1-12" diameter range.

Core Material Advantages: The Science Behind UNS N06625

Inconel 625 is a nickel-chromium-molybdenum-niobium alloy renowned for its solid-solution strengthening mechanism—no post-weld heat treatment required to maintain peak performance . Its precise chemical composition (minimum 58% nickel, 20-23% chromium, 8-10% molybdenum, and 3.15-4.15% niobium-tantalum) creates a robust matrix that resists degradation in extreme conditions .

Key physical and mechanical properties include:

- Density: 8.44 g/cm³ (0.305 lbs/in³)

- Tensile Strength: Minimum 760 MPa (110 ksi), reaching up to 960 MPa for annealed variants

- Yield Strength: 345-414 MPa (50-60 ksi) at 0.2% offset

- Elongation: 30% minimum, ensuring ductility for complex fabrication

- Temperature Resilience: Maintains structural integrity from cryogenic environments to 982°C (1800°F), with short-term resistance up to 1095°C (2000°F)

Critical for aerospace, this alloy is non-magnetic (magnetic permeability 1.0006 when annealed) and exhibits low thermal expansion (7.3-7.7 x 10⁻⁶ in/in/°F from 20-427°C), minimizing stress from temperature fluctuations .

ASTM B446 Compliance & Dimensional Precision

Our round bars adhere strictly to ASTM B446, the industry standard for nickel-alloy hot-rolled and cold-drawn bars . This ensures consistent quality across:

- Diameters: 1" to 12", with tight tolerance control (±0.005" for precision grades) to reduce machining waste.

- Surface Finish: Annealed and descaled surfaces (Ra ≤ 1.6 μm) or polished options for critical aerospace components.

- Lengths: Standard 12’-24’ or custom-cut to your specifications, with straightness tolerance ≤ 0.015"/ft.

Each bar is traceable via a unique heat number, with certification including chemical analysis, mechanical test results, and dimensional reports—essential for aerospace quality management systems (e.g., AS9100).

Aerospace Applications: Built for Extreme Flight Conditions

Inconel 625’s versatility makes it indispensable for mission-critical aerospace components :

- Engine Systems: Turbine casings, combustion chamber liners, and exhaust manifolds rely on its 982°C heat resistance and creep resistance to withstand continuous high-temperature operation.

- Structural Components: Landing gear actuators and wing spar fasteners leverage its high tensile strength and fatigue resistance (even after welding).

- Fluid Management: Fuel and hydraulic lines use 1"-4" diameter bars for corrosion resistance against jet fuels and hydraulic fluids.

- Spacecraft Hardware: Rocket thrust chamber tubes and satellite antenna mounts benefit from its low-temperature toughness and resistance to space debris impact.

Aerospace manufacturers also value its weldability—welded joints retain 80% of base metal strength without cracking, eliminating the need for costly post-weld treatments .

Quality Assurance & Value Proposition

Every round bar undergoes rigorous testing:

- Ultrasonic inspection (per AMS 2631) to detect internal defects.

- Eddy current testing for surface flaw detection.

- Batch-specific corrosion testing in simulated aerospace environments (e.g., salt spray, jet fuel exposure).

We supply both annealed (Grade 1) and solution-treated (Grade 2) variants, with Grade 2 optimized for high-temperature creep resistance up to 1000°C . Our 1-12" diameter range eliminates the need for multiple suppliers, while just-in-time delivery supports tight aerospace production schedules.

Why Choose Our UNS N06625 Round Bars?

Aerospace engineers trust our products for:

- Regulatory Readiness: Compliance with ASTM B446, AMS 5666, and AS9100 standards.

- Performance Consistency: Tight control over niobium and molybdenum content ensures uniform strength.

- Cost Efficiency: Precision sizing reduces machining time and material waste.

- Technical Support: Our metallurgists provide application guidance for complex designs (e.g., turbine components).

![]()

![]()

![]()

![]()

推薦されたプロダクト