-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

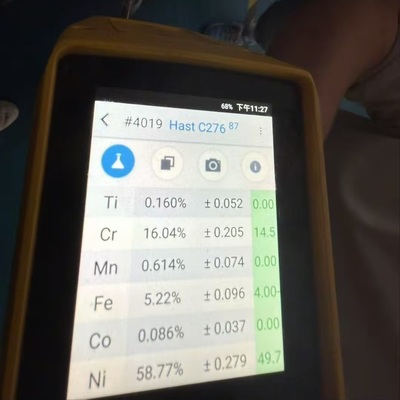

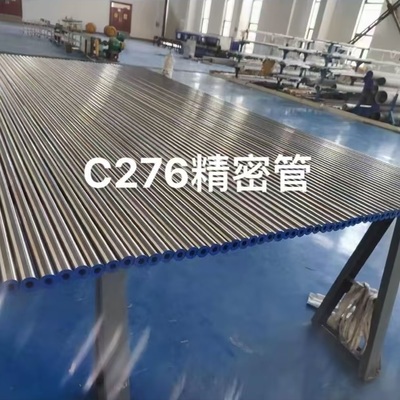

Hastelloy C276 Precision Tubes Seamless/ERW High Corrosion Resistance for Industrial Applications

試供品およびクーポンのための私に連絡しなさい。

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 製品 | Hastelloy C276パイプ | 学年 | Hastelloy C276 |

|---|---|---|---|

| 直径 | 6-219mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | 明るい |

| ハイライト | Hastelloy C276 seamless tubes,corrosion resistant nickel alloy tubes,industrial Hastelloy C276 ERW tubes |

||

Hastelloy C276 Precision Tubes Seamless/ERW High Corrosion Resistance for Industrial Applications

More Specification Informations

| Products Name | Hastelloy C276 pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy C276 Precision Tubes: Seamless & ERW for Superior Corrosion Resistance in Industrial Applications

What are Hastelloy C276 Precision Tubes?

Hastelloy C276 precision tubes are high-performance nickel-molybdenum-chromium alloy tubes manufactured to extremely tight tolerances and strict quality standards. Available in both seamless (AMS 5759) and electric resistance welded (ERW) forms, these tubes are engineered for exceptional corrosion resistance, mechanical strength, and reliability in the most demanding industrial environments. Their precision dimensions make them ideal for critical applications where consistency and performance are paramount.

Key Features & Advantages

-

Exceptional Corrosion Resistance: Hastelloy C276 is renowned for its outstanding resistance to a wide range of severe corrosive chemicals. It performs excellently in reducing environments like hydrochloric and sulfuric acids, as well as in oxidizing settings, and is highly resistant to pitting, crevice corrosion, and stress corrosion cracking (SCC).

-

Two Manufacturing Types:

-

Seamless Tubes: Ideal for high-pressure applications, offering uniform structure and strength throughout, with no risk of weld-line defects.

-

ERW Tubes (Electric Resistance Welded): A cost-effective alternative for many applications, offering excellent corrosion resistance and high dimensional accuracy with a consistent weld seam.

-

-

High-Temperature Stability: Maintains excellent mechanical properties and corrosion resistance in extreme temperatures, from cryogenic conditions up to approximately 1000°C (1800°F).

-

Precision Engineering: Manufactured to exact inner diameter (ID), outer diameter (OD), and wall thickness specifications, ensuring perfect fit and performance in complex systems.

-

Superior Mechanical Properties: Offers high tensile and yield strength, good fabricability, and weldability.

Primary Industrial Applications

Hastelloy C276 precision tubes are critical components across numerous challenging industries:

-

Chemical Processing Industry (CPI): For reactor coils, heat exchanger tubing, condenser tubes, and piping systems handling harsh acids, chlorides, and solvents.

-

Pollution Control & FGD Systems: Used in flue gas desulfurization (FGD) units, scrubbers, and ducting to resist corrosive sulfur compounds and chlorides.

-

Pharmaceutical Industry: In process equipment where ultra-high purity and resistance to corrosive cleaning agents are required.

-

Oil & Gas (Upstream & Downstream): For downhole components, umbilicals, and processing equipment exposed to sour gas (H2S), CO2, and chlorides.

-

Nuclear Fuel Reprocessing: Handles highly corrosive media involved in the reprocessing cycle.

-

Pulp & Paper Industry: Used in digesters and bleaching equipment where chloride-induced stress corrosion cracking is a concern.

-

Waste Treatment: In systems processing aggressive industrial waste.

Technical Specifications (Typical)

-

Standard: ASTM B622 (Seamless), ASTM B626 (Welded)

-

Common Sizes: OD from 1/8" to 4" or more, with custom sizes available.

-

Wall Thickness: Customizable to meet specific pressure and mechanical requirements.

-

Condition: Annealed and pickled to ensure optimal corrosion resistance.

-

Certification: Supplied with Mill Test Certificates (MTC) conforming to EN 10204 3.1.

Why Choose Our Hastelloy C276 Precision Tubes?

We supply premium-quality Hastelloy C276 seamless and welded precision tubing that meets the highest international standards. Our products undergo rigorous quality control and non-destructive testing (NDT) to guarantee performance and longevity in your most critical applications. We provide expert technical support to help you select the right type (seamless vs. ERW) and specification for your project needs

![]()

![]()

![]()

![]()