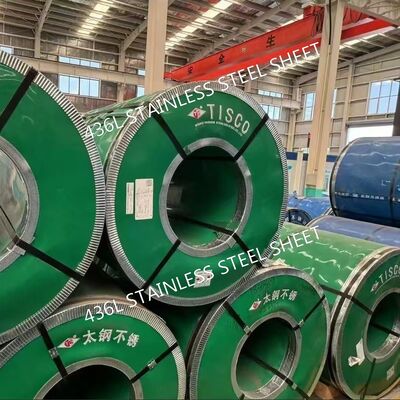

TISCO 436L Piastra ferritica in acciaio inossidabile a basso tenore di carbonio, alta durata per applicazioni industriali

Specificativi delle lamiere in acciaio inossidabile

| Nome |

436L Placca in acciaio inossidabile |

| Il nostro grado |

Serie 200: 201 202

Serie 300: 301 304, 304L, 304H, 309S, 310S,314,316L,316Ti,316H,316LN,317L,321,329,347

Serie 400: 409L410,410S,415,416,420,430,431436 litre.439,441,443,444,445,446

Super acciaio inossidabile: 904L,926254SMO, 654SMO, 15-5PH, 17-4PH, 17-7PH, ecc.

Lega di nichel: C276, C22, G35, Lega X, Monel 400, K500, Inconel 600,601,617,625,718Incoloy 800,800H,800HT,825. ecc

|

| Tecnica |

Rotolato a caldo, laminato a freddo, forgiato |

| Norme |

JIS, AISI, ASTM, DIN, TUV, BV, SUS, ecc. |

| Spessore |

0.1 ¢ 80,0 mm |

| Intervallo larghezza |

10 mm 2000 mm |

| Distanze |

Personalizzato |

| Finisci. |

2B, 2D, NO.1- No, BA.4, 8k, spazzolato, capelli, rivestimento PVD, sabbiato |

| Servizio |

Taglio laser, piegatura |

| Campione |

Disponibile |

Placca di acciaio inossidabile ferritico TISCO 436L Low Carbon, High Durability for Industrial Applications

In demanding industrial environments—ranging from automotive exhaust systems and heat exchangers to chemical processing equipment and architectural cladding—material selection is critical to ensuring long-term performanceTISCO (Taiyuan Iron & Steel Group Co., Ltd.), il principale produttore cinese di acciaio inossidabile e produttore riconosciuto a livello mondiale,offre 436L piastra di acciaio inossidabile ferritico progettato per una resistenza alla corrosione superioreCon la sua composizione a basso tenore di carbonio e stabilizzata in titanio, il TISCO 436L offre una durata eccezionale in condizioni di servizio ad alte temperature e corrosive.rendendolo una scelta preferita in molti settori industriali.

Cos'è l'acciaio inossidabile TISCO 436L?

TISCO 436L è un acciaio inossidabile ferritico ad alta purezza e basso tenore di carbonio appartenente alla serie AISI 400.con una tensione di potenza superiore a 50 kPa,. il numero L indica un contenuto di carbonio molto basso (≤ 0,03%),che impedisce la precipitazione di carburo di cromo durante la saldatura o l'esposizione a temperature elevate, mantenendo così la resistenza alla corrosione nelle zone colpite dal calore.

Prodotto in stretti controlli di qualità presso le strutture TISCO's all'avanguardia, questo grado è conforme agli standard internazionali tra cui:

- JIS G 4304 / G 4305 (SUS436L)

- ASTM A240 / A666

- GB/T 4237 / 4239 (norme nazionali cinesi)

Ciò garantisce una compatibilità globale e prestazioni coerenti per i progetti industriali orientati all'esportazione.

Caratteristiche e vantaggi principali

| Caratteristica |

Benefici |

| Basso tenore di carbonio (C ≤ 0,03%) |

Elimina la sensibilizzazione; ideale per componenti saldati |

| Stabilizzazione del titanio (Ti ≥ 4×(C+N)) |

Previene la corrosione intergranulare; migliora la stabilità ad alta temperatura |

| Aggiunta di molibdeno (0,751,25%) |

Migliora la resistenza alla corrosione delle fessure e delle crepe indotte dal cloruro |

| Microstruttura ferritica |

Magnetico, eccellente conduttività termica, bassa espansione termica |

| Composizione priva di nichel |

Cost-effective; immune alla volatilità dei prezzi del nichel |

| Resistenza alle alte temperature |

Stabile fino a 700 °C; adatto ai sistemi di scarico e di scambio di calore |

Questi attributi rendono TISCO 436L particolarmente utile in applicazioni in cui la lunga durata di servizio, la manutenzione minima e la conformità normativa non sono negoziabili.

Applicazioni industriali primarie

- Sistemi di scarico per autoveicoli

Utilizzato nei silenziatori, nelle conchiglie dei catalizzatori, nei tubi di scarico e nelle valvole EGR, specialmente nelle regioni con forti salinismi stradali.

- Scambiatori di calore e caldaie

Trasferimento termico efficiente combinato con resistenza all'ossidazione a temperature elevate.

- Componenti dell'apparecchio

I rivestimenti delle lavastoviglie, i rivestimenti dei forni e i tamburi delle lavatrici beneficiano della sua formabilità e della sua pulizia.

- Rivestimenti architettonici (interni/esterni)

Offre un aspetto estetico con una protezione da corrosione duratura in ambienti urbani o costieri.

- Tubi e condotte industriali

Gestisce gas e condensati leggermente corrosivi in impianti chimici e di generazione di energia.

Composizione chimica (tipico TISCO 436L)

| Elemento |

Contenuto (%) |

Scopo |

| Carbonio (C) |

≤ 0.03 |

Minimizza la formazione di carburo di Cr |

| Cromo (Cr) |

16.0 ¢18.0 |

Forma uno strato di ossido passivo per la resistenza alla corrosione |

| Molibdeno (Mo) |

0.75 ¢1.25 |

Migliora la resistenza alla corrosione da buche/fessure |

| Titanio (Ti) |

≥ 4 × C + N |

Stabilizza il carbonio/azoto; migliora l'integrità della saldatura |

| Manganese (Mn) |

≤ 10 |

Aiuti alla deossidazione e lavorabilità a caldo |

| Silicio (Si) |

≤ 10 |

Migliora la resistenza alla scala a alte temperature |

| Fosforo (P) |

≤ 0.04 |

Controllati per evitare la fragilità |

| Sulfuro (S) |

≤ 0.03 |

Garantisce una buona finitura e duttilità della superficie |

| Ferro (Fe) |

Bilancio |

Metalli comuni |

Nota: la composizione effettiva può essere perfezionata in base alle specifiche del cliente e alle esigenze dell'uso finale.

Proprietà meccaniche e fisiche (condizione di ricottura)

| Immobili |

Valore tipico |

| Resistenza alla trazione |

450 ∼ 600 MPa |

| Forza del rendimento (0,2% di compensazione) |

250 ‰ 400 MPa |

| L'allungamento |

25-30% |

| Durezza (HRB) |

≤ 85 |

| Densità |

70,70 g/cm3 |

| Conduttività termica (100°C) |

¥26 W/m·K |

| Coefficiente di espansione termica (20-100°C) |

10.4 × 10−6 /°C |

| Resistenza elettrica |

0,60 μΩ·m |

Queste proprietà supportano un'eccellente formabilità, capacità di disegno profondo e stabilità dimensionale durante la fabbricazione e il funzionamento.

Specifiche di prodotto disponibili da TISCO

| Parametro |

Dettagli |

| Modulo |

Piastre laminate a caldo, lamiere laminate a freddo, bobine |

| Spessore |

0.3 mm 6.0 mm (personalizzabile) |

| Larghezza |

Fino a 2000 mm |

| Distanze |

Standard: 2000-6000 mm; disponibile in taglio lungo |

| Finitura superficiale |

2B, 2D, BA (Bright Annealed), n.1, Linea dei capelli, su misura |

| Tipo di bordo |

Fenditura, fresatura, rasatura |

| Imballaggio |

Carta impermeabile + cinture in acciaio; ICV per l'esportazione |

Tutti i prodotti sono sottoposti a rigorose ispezioni per la piattezza, i difetti superficiali e l'accuratezza dimensionale secondo ISO 9001 e IATF 16949 (per il materiale di grado automobilistico).

Perché scegliere TISCO 436L rispetto a quelli concorrenti?

| Confronto |

430 |

TISCO 436L |

304 |

316 |

| Resistenza alla corrosione |

Moderato |

Alto (Mo + Ti) |

Altezza |

Molto elevato |

| Saldabilità |

Poor (sensibilizza) |

Ottimo (stabilizzato) |

- Bene. |

Eccellente. |

| Temperatura di servizio massima |

¥ 600°C |

¥ 700°C |

¥870°C |

¥870°C |

| Costo |

$ |

** |

|

|

Sostenibilità e conformità ambientale

TISCO è impegnata nella produzione verde:

- >70% di materie prime riciclate

- Produzione ad alta efficienza energetica mediante forni ad arco elettrico avanzati

- Piena conformità alle direttive RoHS, REACH e ELV (Veicolo fuori uso)

- Zero emissioni pericolose nei processi di finitura

La scelta di TISCO 436L sostiene gli obiettivi di economia circolare riducendo al contempo i costi del ciclo di vita.

Assicurazione della qualità e supporto globale

Ogni lotto di TISCO 436L include:

- Certificato di prova di mulino (EN 10204 3.1)

- Relazione di analisi spettrometrica

- Dati di prova meccanica

- Ispezione delle correnti ad ultrasuoni o a vortice (su richiesta)

La rete di distribuzione globale di TISCO® garantisce la consegna tempestiva in Nord America, Europa, Asia sudorientale e Medio Oriente.con il supporto di tecnici tecnici della vendita che assistono con la selezione del materiale e la consulenza di lavorazione.

Per le applicazioni industriali che richiedono una robusta resistenza alla corrosione, resistenza termica e controllo dei costi, la piastra in acciaio inossidabile ferritico TISCO 436L rappresenta un punto di riferimento per prestazioni e affidabilità.Sostenuta da decenni di esperienza metallurgica e da continui investimenti in ricerca e sviluppo, TISCO offre un prodotto che soddisfa e spesso supera le aspettative ingegneristiche globali.

Sia che stiate progettando sistemi di scarico di nuova generazione, scambiatori di calore industriali, o facciate di edifici sostenibili, specificando TISCO 436L garantisce durabilità, conformità,e efficienza operativa a lungo termine.

TISCO 436L acciaio inossidabile, 436L lamiera di acciaio inossidabile ferritico, uso industriale in acciaio inossidabile a basso tenore di carbonio, SUS436L TISCO, acciaio inossidabile stabilizzato al titanio, acciaio inossidabile al molibdeno 436Lpiastra di acciaio inossidabile di alta durata, acciaio inossidabile per scarichi automobilistici TISCO, acciaio industriale resistente alla corrosione, lamiera di acciaio inossidabile senza nichel.

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro