-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

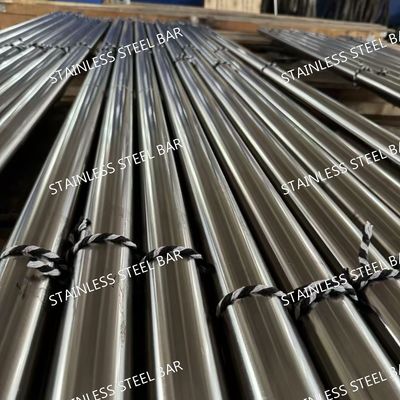

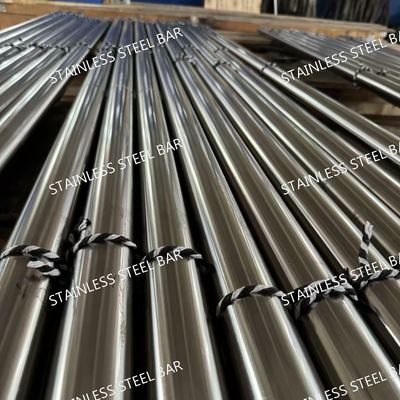

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

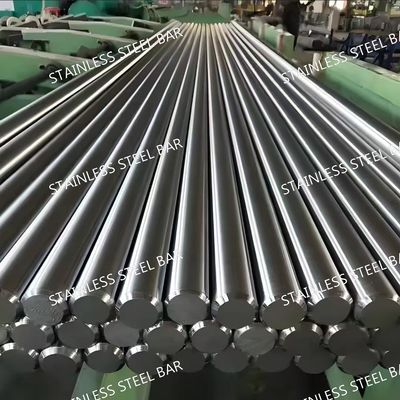

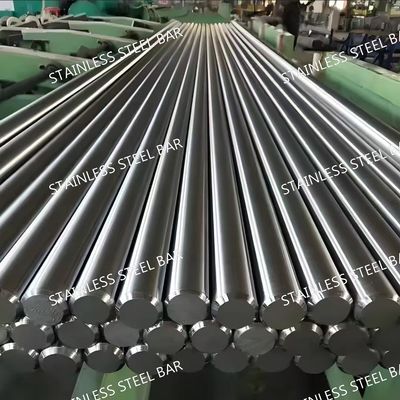

316F Barre di lucidatura in acciaio inossidabile Alta resistenza, anticorrosione, ingegneria di precisione

| Luogo di origine | Cina |

|---|---|

| Marca | Delta |

| Certificazione | ISO 9001 |

| Numero di modello | 316F |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 3-4 USD/Kg |

| Imballaggi particolari | scatola di legno o rivestimento in carta impermeabile |

| Tempi di consegna | 5 - 10 giorni |

| Termini di pagamento | T/T, Western Union |

| Capacità di alimentazione | 50 tonnellate al mese |

| Nome dei prodotti | Barra in acciaio inossidabile 316F | Diametro | 10 - 350mm |

|---|---|---|---|

| Lunghezza | 6m o tagliare qualsiasi lunghezza come richiesta | Superficie | Sottaceti o brillanti |

| Servizio | Taglio | Standard | ASTM Din GB en |

| Altri prodotti | barra rotonda, barra quadrata, barra piatta.etc | Tecnica | Laminato caldo |

| Evidenziare | Aste di lucidatura in acciaio inossidabile 316F,barre di acciaio inossidabile di alta resistenza,per la fabbricazione di apparecchi per la trasmissione elettronica |

||

316F Barre di lucidatura in acciaio inossidabile Alta resistenza, anticorrosione, ingegneria di precisione

Specifica dei prodotti

| Nome dei prodotti | 316F Barra rotonda in acciaio inossidabile |

| Grado |

303,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660C276,600,601,625,718,800800H,825,926. ecc |

| Diametro dei prodotti | φ3 mm - φ350 mm |

| Distanze | 6 m/pcs o tagliando su richiesta |

| Superficie | Finitura di decapaggio, finitura lucida |

| Norme | ASTM JIS, GB, DIN EN |

| Servizio | Taglio |

| Altre forme | Quadrato, piatto, esagonale, rotondo, ecc. |

| Porto di carico | Porto di Shanghai |

| MOQ | 50 kg |

316F Barre di lucidatura in acciaio inossidabile Alta resistenza, anticorrosione, ingegneria di precisione

316F barre di lucidatura in acciaio inossidabilesono progettati per la finitura superficiale ad alte prestazioni nelle industrie che richiedonoresistenza alla corrosione superiore,elevata resistenza, eingegneria di precisione. Con una maggiore lavorabilità, queste barre sono ideali per creare superfici lisce e lucide su parti esposte a ambienti difficili.leghe 316F a lavorazione libera, queste barre sono perfette per l'uso in applicazioni che vanno dall'industria navale e aerospaziale all'industria medica e chimica.

La presente guida copre lacomposizione chimica,proprietà meccaniche,norme,caratteristiche,Applicazioni, e altro ancora, per aiutarvi a capire perché le barre di lucidatura in acciaio inossidabile 316F sono la scelta ideale per le vostre esigenze di finitura superficiale.

Composizione chimica delle barre di lucidatura in acciaio inossidabile 316F

Il...Acciaio inossidabile 316Fla lega è una versione di lavorazione libera dello standardAcciaio inossidabile 316, con un tenore di zolfo più elevato che migliora la lavorabilità.316F:

| Elemento | Percentuale (%) | Ruolo nella lega |

|---|---|---|

| Carbonio (C) | ≤ 0.08 | Riduce la durezza, migliora la lavorabilità e previene la fragilità |

| Manganese (Mn) | ≤ 200 | Migliora la resistenza all'usura |

| Silicio (Si) | ≤ 100 | Migliora la resistenza all'ossidazione e al calore |

| Fosforo (P) | ≤ 0.045 | Limita il rischio di corrosione e frattura |

| Sulfuro (S) | 0.10 ¢ 0.30 | Migliora la lavorabilità, conferendo alla lega la sua caratteristica di "libera lavorazione" |

| Cromo (Cr) | 16.0 ¢18.0 | Aumenta la resistenza e la resistenza alla corrosione |

| Nilo (Ni) | 10.0 ¢14.0 | Fornisce formabilità, migliora la resistenza alla corrosione e alla calore |

| Molibdeno (Mo) | 2.00 ¢3.00 | Migliora la resistenza alle crepe, alla corrosione delle fessure e agli ambienti marini |

| Ferro (Fe) | Bilancio | Forma la base dell'lega, garantendo stabilità e resistenza |

Il...molibdeno (Mo)Il contenuto di acciaio inossidabile 316F svolge un ruolo cruciale nel rendere la lega resistente alla corrosione indotta dai cloruri, che è una preoccupazione comune nelle industrie marine e chimiche.

Proprietà meccaniche delle barre di lucidatura in acciaio inossidabile 316F

Le barre di lucidatura in acciaio inossidabile 316F mantengono eccellenti proprietà meccaniche che le rendono adatte sia per applicazioni strutturali che per compiti di finitura superficiale.Di seguito è riportato un riassunto delle principali proprietà meccaniche:

| Immobili | Valore |

|---|---|

| Resistenza alla trazione (Rm) | ≥ 515 MPa (74.800 psi) |

| Forza del rendimento (0,2% di compensazione) | ≥ 205 MPa (29,725 psi) |

| L'allungamento | ≥ 40% (duttile, buono per la piegatura e la formazione) |

| Durezza (Rockwell B) | 85 ¢ 95 HRB |

| Durezza all'impatto | Ottima resistenza agli urti a basse temperature |

| Modulo di elasticità | 193 GPa (28 x 106 psi) |

| Rapporto di Poisson | 0.30 |

| Densità | 70,98 g/cm3 |

Queste proprietà meccaniche rendono le barre di lucidatura in acciaio inossidabile 316F molto adatte perapplicazioni ad alta resistenzache richiedono durabilità e resistenza allo stress meccanico.

Norme per l'acciaio inossidabile 316F

Le barre in acciaio inossidabile 316F sono conformi a diverse norme industriali che ne garantiscono la qualità e le prestazioni.

-

ASTM A276¢ Specifica standard per barre e forme in acciaio inossidabile

-

ASTM A479 Specifica standard per le barre in acciaio inossidabile da utilizzare in caldaie e altri recipienti a pressione

-

ISO 683-13Barre di acciaio trattate termicamente per applicazioni strutturali

-

DIN 17440Barre, barre e sezioni in acciaio inossidabile (norma europea)

-

UNS S31620Sistema di numerazione unificato per l'acciaio inossidabile (fornisce l'identificazione delle leghe)

Queste norme garantiscono che le barre in acciaio inossidabile 316F siano state testate per la composizione chimica, le proprietà meccaniche e l'integrità superficiale, rendendole adatte per applicazioni ad alta precisione.

Caratteristiche delle barre di lucidatura in acciaio inossidabile 316F

-

Resistenza alla corrosione superiore

-

Il contenuto di molibdeno aumenta la resistenza aiCloruri,acidi, ealcalini, che lo rende ideale perambienti marini,lavorazione chimica, eapplicazioni per acqua salata.

-

-

Miglioramento dell'abilità meccanica

-

L'elevato contenuto di zolfo migliora la lavorabilità dell'acciaio inossidabile 316F, consentendotaglio più veloce,modellazione più facile, emeno usura degli attrezziQuesto rende le barre di lucidatura 316F adatte per le industrie che richiedono una produzione di grandi volumi e una finitura precisa.

-

-

Ottima finitura superficiale

-

Le barre 316F sono altamente levigate per ottenere unsuperficie liscia, lucida e riflettente, che è essenziale per le applicazionidispositivi medici,aerospazialecomponenti, eattrezzature per uso alimentare.

-

-

Alta resistenza e durata

-

Nonostante i miglioramenti nella lavorabilità, il 316F mantiene un'eccellente resistenza alla trazione e alla resa, garantendo che possa gestire applicazioni pesanti, anche in condizioni difficili.

-

-

Proprietà non magnetiche

-

L'acciaio inossidabile 316F ènon magnetici, che è utile nelle applicazioni in cui le proprietà magnetiche interferiscono con le operazioni (ad esempio, apparecchiature di imaging medica).

-

Applicazioni delle barre di lucidatura in acciaio inossidabile 316F

Le barre di lucidatura in acciaio inossidabile 316F sono ampiamente utilizzate in industrie che richiedono finiture superficiali precise e elevata resistenza.

1.Industria marina e offshore

-

Le barre 316F sono utilizzate nelmarinoambiente a causa della loro elevata resistenza alla corrosione dell'acqua salata.

-

Lustrare alberi, eliche e altre attrezzature marine.

-

Fittings resistenti alla corrosioneper piattaforme petrolifere, navi e apparecchi subacquei.

2.Aerospaziale e dell'aviazione

-

Polizione dicomponenti di aeromobili- eattrezzature aerospaziali.

-

Adatto per:finiture ad alte prestazionisu parti di aeromobili, garantendo un minimo di usura in condizioni estreme.

3.Strumenti medici e chirurgici

-

Ideale per la realizzazione di finiture lucide sustrumenti chirurgici,Impianti, edispositivi medici.

-

La superficie liscia è essenziale per ridurre la crescita batterica e aumentare gli standard igienici negli ambienti medici.

4.Produzione alimentare e farmaceutica

-

Barre lucidatesono utilizzati per creare superfici lisce e igieniche perattrezzature per la trasformazione alimentare.

-

Macchine e apparecchi farmaceuticiin cui la resistenza alla corrosione e la finitura liscia sono essenziali per mantenere la purezza del prodotto.

5.Trasformazione chimica

-

Produzionetubi, valvole e componenti del reattorequando la corrosione chimica è un problema.

-

Polizione degli interni e degli accessori del reattoreacido- ealcalinoambienti.

6.Strumenti e stampi di precisione

-

Polizione della muffa- eattrezzatureper la produzione ad alta precisione.

-

Applicazioni infusione a stampo,stampaggio a iniezione, e altre aree che richiedono finiture superficiali di alta precisione.

Altri prodotti in acciaio inossidabile 316F

Oltre alle barre di lucidatura, l'acciaio inossidabile 316F è disponibile in varie forme per diverse applicazioni:

-

316F Barre di acciaio inossidabile: Disponibile in forme rotonde, quadrate ed esagonali per una versatile lavorazione.

-

316F Lastre e lastre di acciaio inossidabile: Utilizzato in applicazioni che richiedonograndi superfici.

-

316F Tubi in acciaio inossidabile: Adatto per tubi ad alta resistenza nell'industria chimica, farmaceutica e alimentare.

-

316F fili di acciaio inossidabile: Per uso nella saldatura e nella messa a punto in applicazioni industriali.

Imballaggio e spedizione delle barre di lucidatura in acciaio inossidabile 316F

Siamo particolarmente attenti all'imballaggio e alla spedizione per assicurarci che il nostro prodotto316F barre di lucidatura in acciaio inossidabileArrivano in perfette condizioni:

-

Imballaggio:

-

Le barre di lucidatura sono confezionate inavvolgimento protettivo, qualiconfezione riducenteoconfezione a bolle, per evitare danni alla superficie durante il trasporto.

-

Casse di legnoocontenitori metallicisono utilizzati per spedizioni sfuse per ridurre al minimo i movimenti e il rischio di graffi o corrosione.

-

-

Trasporti marittimi:

-

Offriamotrasporto marittimo internazionalecon partner logistici affidabili.

-

La consegna può essere organizzataespressoostandarda seconda delle scadenze del progetto.

-

Domande frequenti (FAQ)

1Che cosa rende il 316F diverso dal normale 316 in acciaio inossidabile?

-

316Fcontiene un tenore di zolfo più elevato, il che lo rende unmacchinatura liberaQuesto migliora la sua lavorabilità, consentendo una produzione più veloce e finiture più lisce rispetto al 316 normale.

2. L'acciaio inossidabile 316F è adatto agli ambienti marini?

-

Sì, 316F offreeccellente resistenza alla corrosione, specialmente controacqua salata- eCloruri, che lo rende una scelta ideale perapplicazioni marine.

3Il 316F può essere utilizzato nelle attrezzature di trasformazione alimentare?

-

La superficie liscia e lucida delle barre in acciaio inossidabile 316F garantisceigienicoCondizioni indi qualità alimentare- efarmaciattrezzature.

4Quali dimensioni sono disponibili per le barre di lucidatura 316F?

-

Le barre 316F sono disponibili in vari diametri, in genere dada 2 mm a 30 mmLe dimensioni personalizzate possono essere organizzate su richiesta.

5Come devono essere conservate le barre di lucidatura in acciaio inossidabile 316F?

-

Conservare in unasciutto, frescoproteggere da radiazioni solari dirette e da umidità.abrasione- eContaminazioneutilizzandocoperture protettivecome pellicole di plastica o di olio.

Conclusioni

Il...316F barre di lucidatura in acciaio inossidabileoffrire il perfetto equilibrio dielevata resistenza,resistenza alla corrosione, ecapacità di lavorazione, rendendoli ideali per applicazioni di ingegneria di precisione in una vasta gamma di industrie.marino,aerospaziale,medico, olavorazione chimica, 316F fornisce la durata e la qualità di finitura necessarie per soddisfare gli standard più esigenti.

Con eccezionaleresistenza chimica,capacità di lavorazione superiore, e la capacità di raggiungerefiniture simili a specchi, le barre di lucidatura in acciaio inossidabile 316F sono un componente crucialeprocessi di produzione ad alte prestazioniContattaci oggi per ulteriori informazioni o per effettuare un ordine!

![]()

![]()

![]()

![]()