-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

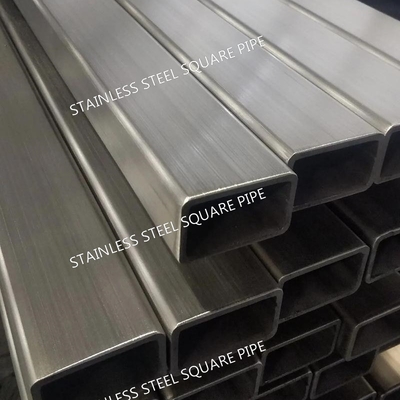

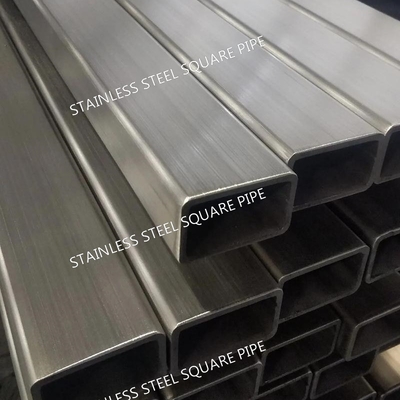

Tubi quadrati in acciaio inossidabile 304 40x40 mm 60x60 mm 80x80 mm tagliati su misura

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | 304 316L 310S 2205 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 5-10 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

Contattimi gratis campioni e buoni.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se avete di preoccupazione, forniamo la guida in linea di 24 ore.

x| Prodotti | Tubo quadrato in acciaio inossidabile | Grado | 304 316L 310S 321 2205 |

|---|---|---|---|

| Diametro | DN10 - DN400 | Distanze | 6m o taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | ASTM EN | Servizio | Taglio |

| Porto di carico | Porto di Shanghai | Spessore | 4.0 - 50.0 mm |

| Evidenziare | Tubi quadrati in acciaio inossidabile 304,tubi di acciaio inossidabile di 40x40 mm,tubi di acciaio inossidabile tagliati su misura |

||

| Attributo | Valore |

|---|---|

| Prodotti | Tubo quadrato in acciaio inossidabile |

| Grado | 304 316L 310S 321 2205 |

| Diametro | DN10 - DN400 |

| Lunghezza | 6m o taglio personalizzato di qualsiasi lunghezza su richiesta |

| Standard | ASTM EN |

| Servizio | Taglio |

| Porto di carico | Porto di Shanghai |

| Spessore | 4.0 - 50.0mm |

I tubi quadrati in acciaio inossidabile 304 sono componenti versatili e resistenti alla corrosione ampiamente utilizzati in diversi settori. Come acciaio inossidabile austenitico, il 304 offre una miscela ideale di formabilità, resistenza e resistenza alla ruggine, rendendolo la scelta più popolare per applicazioni generiche in cui la durata incontra l'economicità.

I tubi quadrati in acciaio inossidabile 304 sono tubi cavi a sezione quadrata realizzati in lega 304, un acciaio austenitico al cromo-nichel. La loro forma quadrata offre rigidità strutturale, rendendoli adatti sia a ruoli portanti che decorativi. A differenza dell'acciaio al carbonio, il 304 resiste all'ossidazione e alla corrosione nella maggior parte degli ambienti, grazie al suo alto contenuto di cromo (18-20%), che forma uno strato protettivo di ossido sulla superficie. Questo grado è non magnetico nel suo stato ricotto e può essere facilmente saldato, piegato o fabbricato in forme complesse.

La composizione chimica dell'acciaio inossidabile 304 definisce le sue proprietà chiave, con intervalli rigorosi delineati negli standard di settore:

| Elemento | Intervallo di contenuto (%) | Funzione |

|---|---|---|

| Cromo (Cr) | 18.0-20.0 | Forma uno strato di ossido passivo, prevenendo ruggine e corrosione. |

| Nichel (Ni) | 8.0-10.5 | Stabilizza la struttura austenitica, migliorando duttilità e tenacità. |

| Carbonio (C) | ≤0.08 | Aggiunge resistenza ma è limitato per evitare la precipitazione di carburi durante la saldatura. |

| Manganese (Mn) | ≤2.0 | Aiuta nella disossidazione e migliora la lavorabilità. |

| Silicio (Si) | ≤1.0 | Migliora la resistenza all'ossidazione ad alta temperatura. |

| Fosforo (P) | ≤0.045 | Controllato per prevenire la fragilità. |

| Zolfo (S) | ≤0.03 | Minimizzato per mantenere la saldabilità e la resistenza alla corrosione. |

I tubi quadrati in acciaio inossidabile 304 bilanciano resistenza e flessibilità, rendendoli adattabili a diverse applicazioni:

| Proprietà | Valore tipico | Standard di prova |

|---|---|---|

| Resistenza alla trazione | 515-690 MPa | ASTM E8 / EN 10002-1 |

| Limite di snervamento (0,2% di offset) | ≥205 MPa | ASTM E8 / EN 10002-1 |

| Allungamento (in 50 mm) | ≥40% | ASTM E8 / EN 10002-1 |

| Durezza (Brinell) | ≤201 HB | ASTM E10 / EN ISO 6506-1 |

| Modulo di elasticità | ~193 GPa | - |

| Densità | 8.0 g/cm³ | - |

I tubi quadrati 304 sono disponibili in un'ampia gamma di dimensioni per soddisfare esigenze specifiche:

- Lunghezza del lato: Da 6 mm a 300 mm (dimensioni comuni: 10×10 mm, 40×40 mm, 100×100 mm)

- Spessore della parete: Da 0,5 mm a 10 mm (pareti più spesse per uso strutturale o ad alta pressione)

- Lunghezza: Standard 6 m; personalizzabile fino a 12 m per grandi progetti

- Opzioni di finitura:

- Finitura al laminatoio (2B): superficie liscia e opaca per uso industriale

- Lucidato (BA/a specchio): superficie lucida e riflettente per applicazioni decorative

- Spazzolato: texture satinata, popolare nelle finiture architettoniche

I tubi quadrati 304 aderiscono agli standard globali per garantire coerenza e qualità:

| Standard | Ente emittente | Applicazione |

|---|---|---|

| ASTM A554 | ASTM International | Tubi meccanici saldati in acciaio inossidabile |

| EN 10217-7 | Comitato europeo | Tubi saldati per pressione (acciaio inossidabile) |

| JIS G3446 | Standard industriali giapponesi | Tubi quadrati in acciaio inossidabile |

| GB/T 12771 | Standard nazionale cinese | Tubi saldati in acciaio inossidabile |

I tubi quadrati 304 sono favoriti in ambienti in cui è richiesta una resistenza generale alla corrosione:

- Architettura e edilizia: Corrimano, balaustre, telai di finestre e facciate decorative (resiste agli agenti atmosferici)

- Industria alimentare e delle bevande: Trasportatori, attrezzature per la produzione di birra e serbatoi di stoccaggio (facile da pulire, non tossico)

- Apparecchiature mediche: Telai di letti d'ospedale, vassoi per strumenti chirurgici (igienici e antiruggine)

- Settore automobilistico: Componenti di scarico, finiture e parti strutturali (resiste moderatamente ai sali stradali)

- Elettrodomestici: Ripiani del frigorifero, porte del forno e parti della lavastoviglie (resiste all'umidità)

- Trattamento delle acque: Tubazioni, alloggiamenti dei filtri e componenti della pompa (resiste alla corrosione dell'acqua pulita)

- Eccellente resistenza alla corrosione: Funziona bene nella maggior parte delle condizioni atmosferiche, acqua dolce e prodotti chimici delicati

- Elevata formabilità: Facilmente saldabile, piegabile o tagliabile, rendendolo adatto alla fabbricazione personalizzata

- Conveniente: Più conveniente rispetto ai gradi di lega superiore come il 316, ideale per progetti sensibili al budget

- Appeal estetico: Le finiture lucide offrono un aspetto elegante e moderno per usi decorativi

- Igienico: La superficie non porosa resiste alla crescita batterica, soddisfacendo gli standard di sicurezza alimentare e medica

Questi gradi sono spesso confrontati con il 304 per casi d'uso specifici:

| Grado | Differenza chiave dal 304 | Ideale per |

|---|---|---|

| 304L | Carbonio inferiore (≤0.03%) per ridurre la precipitazione di carburi | Strutture saldate che richiedono la massima resistenza alla corrosione |

| 316 | Contiene molibdeno (2-3%) per una migliore resistenza ai cloruri | Ambienti marini, costieri o ad alto contenuto di sale |

| 303 | Zolfo più alto per una migliore lavorabilità | Parti che richiedono lavorazioni complesse (ad esempio, elementi di fissaggio) |

| 430 | Ferritico (senza nichel); costo inferiore ma minore resistenza alla corrosione | Applicazioni interne asciutte (ad esempio, finiture di elettrodomestici) |

I tubi quadrati in acciaio inossidabile 304 sono il cavallo di battaglia dei tubi in acciaio inossidabile, offrendo una combinazione vincente di resistenza alla corrosione, formabilità e convenienza. Eccellono nelle applicazioni generiche, dall'edilizia alla trasformazione alimentare, dove durata e versatilità sono fondamentali. Per la maggior parte degli ambienti non aggressivi, il 304 offre prestazioni affidabili senza il costo premium delle leghe di grado superiore.