Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

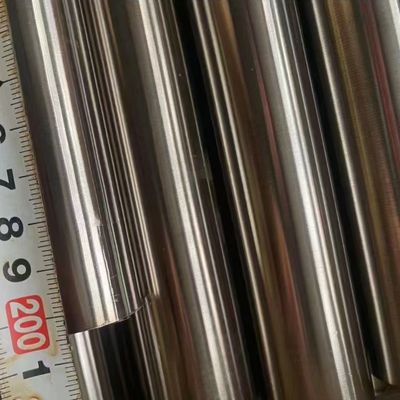

Hastelloy C276 Bright Bar Διαμέτρου 5 - 300mm Bright Polished C276 Rod Custom Cutting σε μήκος

| Τόπος καταγωγής | ΚΙΝΑ |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | Hastelloy C276 |

| Ποσότητα παραγγελίας min | 10 κιλά |

| Τιμή | 40 - 50 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Φωτεινή ράβδος Hastelloy C276 | Βαθμός | Hastelloy C276 |

|---|---|---|---|

| Διάμετρος | 5 - 350mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | ΤΟΜΗ |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Ευφυής |

| Επισημαίνω | Ράβδος Hastelloy C276 γυαλισμένη φωτεινή,Ράβδος κράματος νικελίου C276 κοπή κατά παραγγελία,Ράβδος Hastelloy C276 διαμέτρου 5-300mm |

||

Περιγραφή προϊόντων

Hastelloy C276 Bright Bar Διάμετρος 5 - 300mm Bright Polished C276 Rod Custom Cutting in Length

Περισσότερες Πληροφορίες Προδιαγραφών

| Όνομα Προϊόντων | Hastelloy C276 Bright Bar |

| Διάμετρος | 5 - 350mm |

| Μήκος | custom cutting οποιοδήποτε μήκος κατόπιν αιτήματος |

| Επιφάνεια | bright, Black |

| Μάρκα | DELTA |

| Υπηρεσία | cutting, Polishing |

| MOQ | 2 Kgs |

| Άλλος Τύπος | bar, strip,coil,pipe.sheet, plate,wire.etc |

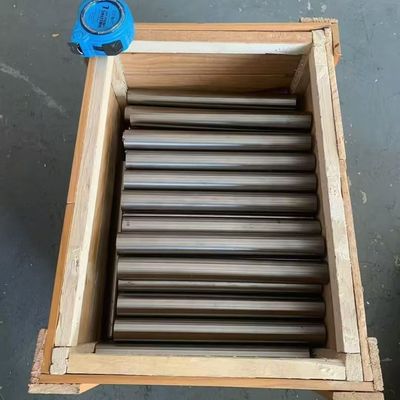

| Συσκευασία | Ξύλινο κουτί |

| Λιμάνι Φόρτωσης | Λιμάνι Σαγκάης |

| Όρος τιμής | EXW,FOB,CIF,CFR |

| Χρόνος παράδοσης | εντός 12 ημερών |

Hastelloy C276 Bright Bar Διάμετρος 5 - 300mm Bright Polished C276 Rod Custom Cutting in Length

Επισκόπηση του Hastelloy C276 Bright Bar

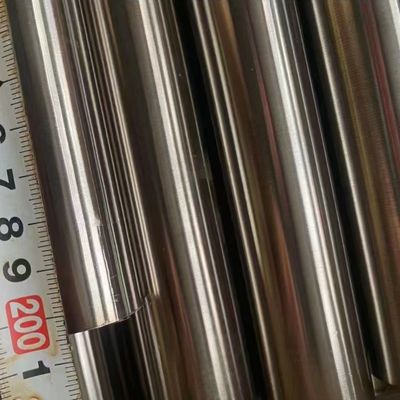

Το Hastelloy C276 bright bar, που ορίζεται ως UNS N10276 και συμμορφώνεται με τα πρότυπα ASTM B574/ASME SB 574, είναι μια ράβδος κράματος νικελίου υψηλής απόδοσης που φημίζεται για την εξαιρετική αντοχή στη διάβρωση και τη μηχανική αντοχή του. Η σειρά προϊόντων μας καλύπτει ένα ευρύ φάσμα διαμέτρων από 5mm έως 300mm, με ένα bright polished φινίρισμα επιφάνειας που επιτυγχάνεται μέσω διαδικασιών λείανσης και στίλβωσης ακριβείας χωρίς κέντρο. Αυτή η επιφανειακή επεξεργασία όχι μόνο ενισχύει την αισθητική εμφάνιση της ράβδου, αλλά ελαχιστοποιεί και τα ελαττώματα της επιφάνειας, μειώνοντας τον κίνδυνο έναρξης διάβρωσης σε σκληρά περιβάλλοντα.

Βασικές Προδιαγραφές & Μηχανικές Ιδιότητες

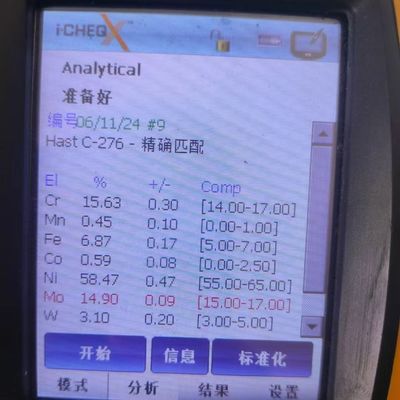

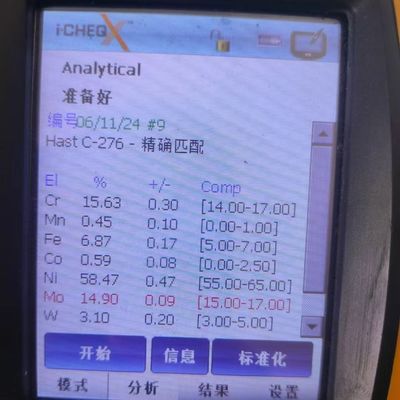

Χημική Σύνθεση

Η ανώτερη απόδοση του Hastelloy C276 προέρχεται από την προσεκτικά ισορροπημένη χημική του σύνθεση. Περιέχει τουλάχιστον 57% νικέλιο ως βασικό στοιχείο, συμπληρωμένο από 14,5–16,5% χρώμιο, 15,0–17,0% μολυβδαίνιο, 3,0–4,5% βολφράμιο και 4,0–7,0% σίδηρο. Τα ιχνοστοιχεία ελέγχονται αυστηρά: άνθρακας ≤0,01%, μαγγάνιο ≤1,00%, πυρίτιο ≤0,08%, κοβάλτιο ≤2,5%, φώσφορος ≤0,04% και θείο ≤0,03%. Αυτή η σύνθεση επιτρέπει στο κράμα να αντιστέκεται τόσο σε οξειδωτικά όσο και σε αναγωγικά διαβρωτικά μέσα.

Μηχανικές & Φυσικές Ιδιότητες

Σε θερμοκρασία δωματίου, οι bright bars Hastelloy C276 παρουσιάζουν αντοχή εφελκυσμού 690–950 MPa, αντοχή διαρροής (0,2% offset) 280–350 MPa και ρυθμό επιμήκυνσης 40–65%. Το κράμα έχει πυκνότητα 8,89 g/cm³ και σημείο τήξης που κυμαίνεται από 1325°C έως 1371°C, επιτρέποντάς του να διατηρεί τη δομική ακεραιότητα σε περιβάλλοντα υψηλής θερμοκρασίας έως και 1000°C. Επιπλέον, διαθέτει εξαιρετική ολκιμότητα και συγκολλησιμότητα, διευκολύνοντας την εύκολη κατασκευή σε πολύπλοκα εξαρτήματα.

Διαστασιακή Ανοχή & Προσαρμογή Μήκους

Τηρούμε αυστηρές διαστασιακές ανοχές, προσφέροντας βαθμούς ανοχής H9/H11 ως στάνταρ, με προσαρμόσιμες επιλογές όπως ανοχές H8, H10 και σειράς K διαθέσιμες κατόπιν αιτήματος. Για το μήκος, το τυπικό μας απόθεμα κυμαίνεται από 50mm έως 6000mm, αλλά παρέχουμε ακριβείς υπηρεσίες κοπής κατά παραγγελία για την κάλυψη συγκεκριμένων απαιτήσεων έργου—είτε μικρά τμήματα για μικρά εξαρτήματα είτε μακριές ράβδοι για εξοπλισμό μεγάλης κλίμακας. Κάθε κομμένο άκρο είναι απογρεζωμένο για να εξασφαλιστεί η ασφάλεια και η συμβατότητα κατά τη συναρμολόγηση.

Βασικά Πλεονεκτήματα Απόδοσης

Απαράμιλλη Αντοχή στη Διάβρωση

Το Hastelloy C276 είναι ένα από τα πιο ανθεκτικά στη διάβρωση κράματα που διατίθενται. Η υψηλή περιεκτικότητά του σε μολυβδαίνιο και χρώμιο παρέχει ανώτερη αντοχή στην οπή που προκαλείται από χλωριούχα, τη διάβρωση ρωγμών και τη ρωγμάτωση λόγω καταπόνησης. Αποδίδει εξαιρετικά σε επιθετικά μέσα όπως υγρό χλώριο, διαλύματα 次氯酸盐, θαλασσινό νερό, μυρμηγκικό οξύ, οξικό οξύ και άλατα χλωριούχου υψηλής συγκέντρωσης όπως χλωριούχο σίδηρο και χλωριούχο χαλκό. Αυτό το καθιστά ιδανικό για εφαρμογές σε εξαιρετικά διαβρωτικά βιομηχανικά περιβάλλοντα.

Σταθερότητα σε Υψηλή Θερμοκρασία

Το κράμα διατηρεί τη μηχανική του αντοχή και την αντοχή στη διάβρωση ακόμη και σε αυξημένες θερμοκρασίες. Σε λέβητες παραγωγής ενέργειας, βιομηχανικούς κλιβάνους και χημικούς αντιδραστήρες που λειτουργούν στους 800–1000°C, αντιστέκεται στην οξείδωση και τη θερμική κόπωση, εξασφαλίζοντας μακροχρόνια αξιοπιστία λειτουργίας. Η θερμική του αγωγιμότητα (9,8 W/(m·°C)) και ο χαμηλός συντελεστής θερμικής διαστολής (11,2 µm/(m·°C)) ενισχύουν περαιτέρω τη σταθερότητά του υπό συνθήκες θερμικής κυκλοφορίας.

Ακρίβεια & Ανθεκτικότητα

Το bright polished φινίρισμα μας υποβάλλεται σε αυστηρό έλεγχο ποιότητας, με την τραχύτητα της επιφάνειας να διατηρείται κάτω από Ra 0,8μm για την αποφυγή προσκόλλησης μόλυνσης και συσσώρευσης διάβρωσης. Κάθε ράβδος ισιώνεται χρησιμοποιώντας προηγμένο εξοπλισμό για να πληροί αυστηρά πρότυπα ευθύτητας, εξαλείφοντας το στρέβλωση κατά την εγκατάσταση και τη χρήση. Η διαδικασία παραγωγής ψυχρής έλξης και θερμικής επεξεργασίας διαλύματος εξασφαλίζει ομοιόμορφη μικροδομή και σταθερή απόδοση σε όλο το μήκος της ράβδου.

Βιομηχανικές Εφαρμογές

Πετροχημική & Χημική Βιομηχανία

Χρησιμοποιείται ευρέως σε διυλιστήρια πετρελαίου, χημικούς αντιδραστήρες, δεξαμενές αποθήκευσης οξέων και αγωγούς που χειρίζονται διαβρωτικά μέσα όπως θειικό οξύ και χλωριωμένα οργανικά. Είναι ιδιαίτερα κατάλληλο για καταλυτικά συστήματα και εξοπλισμό παραγωγής MDI (μεθυλενοδιφαινυλοδιισοκυανικό).

Παραγωγή Ενέργειας & Πυρηνική Βιομηχανία

Εφαρμόζεται σε πολιτικούς πυρηνικούς σταθμούς, λέβητες σταθμών παραγωγής ενέργειας, εναλλάκτες θερμότητας και συστήματα εξάτμισης ατμού, όπου αντέχει σε υψηλές θερμοκρασίες και διαβρωτικά ψυκτικά. Η αντοχή του στην ακτινοβολία το καθιστά επίσης ένα προτιμώμενο υλικό για εξαρτήματα πυρηνικών αντιδραστήρων.

Θαλάσσια & Περιβαλλοντική Μηχανική

Ιδανικό για μονάδες αφαλάτωσης θαλασσινού νερού, υπεράκτιες πλατφόρμες πετρελαίου και συστήματα αποθείωσης καυσαερίων (FGD). Αντιστέκεται στη διάβρωση του θαλασσινού νερού και την υποβάθμιση που προκαλείται από το διοξείδιο του θείου, που χρησιμοποιείται σε 洗涤塔,re heaters, και ανεμιστήρες υγρού αερίου.

Άλλα Πεδία

Στη βιομηχανία χαρτοπολτού, κατασκευάζει δοχεία μαγειρέματος και λεύκανσης. στον ιατρικό τομέα, χρησιμοποιείται για εξαρτήματα οργάνων ανθεκτικά στη διάβρωση. Επίσης, εξυπηρετεί τις αεροδιαστημικές, αυτοκινητοβιομηχανικές και ηλεκτρονικές βιομηχανίες που απαιτούν εξαρτήματα υψηλής αντοχής και ανθεκτικά στη διάβρωση.

Διασφάλιση Ποιότητας & Logistics

Όλες οι bright bars Hastelloy C276 υποβάλλονται σε αυστηρή επιθεώρηση ποιότητας, συμπεριλαμβανομένης της ανάλυσης χημικής σύνθεσης (σύμφωνα με τα πρότυπα ASTM), της δοκιμής μηχανικών ιδιοτήτων και των μη καταστροφικών δοκιμών (NDT) για εσωτερικά ελαττώματα. Παρέχουμε πιστοποίηση ISO, SGS και BV για να εγγυηθούμε την ποιότητα του προϊόντος. Για τη συσκευασία, χρησιμοποιούμε τυπική συσκευασία θαλάσσης εξαγωγής με στρώματα ανθεκτικά στην υγρασία για την αποφυγή διάβρωσης κατά τη μεταφορά. Η παραγωγική μας ικανότητα φτάνει τους 10.000 τόνους ετησίως, εξασφαλίζοντας έγκαιρη παράδοση ακόμη και για μεγάλες παραγγελίες (ελάχιστη ποσότητα παραγγελίας: 1 τόνος).

Γιατί να επιλέξετε το Hastelloy C276 Bright Bar μας?

- Ολοκληρωμένες Προδιαγραφές: Κάλυψη διαμέτρου 5–300mm και κοπή κατά παραγγελία μήκους καλύπτουν ποικίλες ανάγκες έργων.

- Ανώτερη Απόδοση: Η κορυφαία στην βιομηχανία αντοχή στη διάβρωση και η σταθερότητα σε υψηλή θερμοκρασία μειώνουν το κόστος συντήρησης.

- Κατασκευή Ακριβείας: Η bright polished επιφάνεια και οι αυστηρές ανοχές εξασφαλίζουν εύκολη ενσωμάτωση σε πολύπλοκα συστήματα.

- Αξιόπιστη Ποιότητα: Η πιστοποιημένη παραγωγή και οι αυστηρές δοκιμές εγγυώνται σταθερή απόδοση.

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα