-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

High-Precision Hastelloy C276 Tubes ASTM B622/B619 Standard Custom Sizes for Chemical Processing

| Τόπος καταγωγής | ΚΙΝΑ |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | Hastelloy C276 |

| Ποσότητα παραγγελίας min | 10 κιλά |

| Τιμή | 40 - 50 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

x| Προϊόντα | Hastelloy C276 σωλήνες | Βαθμός | Hastelloy C276 |

|---|---|---|---|

| Διάμετρος | 6 - 219mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Ευφυής |

| Επισημαίνω | Hastelloy C276 tubes chemical processing,ASTM B622 nickel alloy tubes,custom size Hastelloy C276 tubes |

||

High-Precision Hastelloy C276 Tubes ASTM B622/B619 Standard Custom Sizes for Chemical Processing

More Specification Informations

| Products Name | Hastelloy C276 pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

High-Precision Hastelloy C276 Tubes: ASTM B622/B619 Standard & Custom Sizes for Demanding Chemical Processing

Introduction to High-Precision C276 Alloy Tubing

In the most aggressive industrial environments, where failure is not an option, high-precision Hastelloy C276 tubing stands as a benchmark for reliability. These tubes are not merely conduits; they are critically engineered components manufactured to exacting dimensional tolerances and metallurgical standards. Specifically designed for applications involving severe corrosive challenges, such as those found in chemical processing, pollution control, and pharmaceutical industries, precision C276 tubes ensure system integrity, safety, and longevity. This product information sheet details our range of ASTM B622 (seamless) and ASTM B619 (welded) high-precision tubing, emphasizing our capability to deliver custom-sized solutions for your unique operational requirements.

Unmatched Material Properties: Why Hastelloy C276?

Hastelloy C276, a nickel-molybdenum-chromium superalloy with added tungsten, is the material of choice for combating the most formidable corrosive agents. Its exceptional performance stems from a unique composition that provides:

-

Broad-Spectrum Corrosion Resistance: Excellent resistance to both oxidizing and reducing media, including hot hydrochloric and sulfuric acids. It is highly resistant to localized attack such as pitting and crevice corrosion, and to stress corrosion cracking (SCC) caused by chlorides.

-

Superior Thermal Stability: Maintains outstanding mechanical properties and corrosion resistance over a wide temperature range, from cryogenic temperatures up to 1000°C (1832°F).

-

Excellent Fabricability: Can be readily formed and welded using standard techniques, making it suitable for fabricating complex systems.

Compliance with Stringent ASTM Standards: B622 & B619

Our high-precision tubing is produced in strict compliance with internationally recognized ASTM standards, guaranteeing material quality, chemical composition, and mechanical properties.

-

ASTM B622: This standard covers seamless nickel and nickel-cobalt alloy pipe and tube. Tubes produced to this standard are ideal for high-pressure applications, offering homogeneous structure and superior strength with no risk of weld-seam contamination.

-

ASTM B619: This standard covers welded nickel and nickel-cobalt alloy pipe and tube. Utilizing advanced electric resistance welded (ERW) or laser welding techniques, these tubes offer a cost-effective alternative for many applications while maintaining excellent corrosion resistance and dimensional precision.

Our manufacturing process ensures full traceability from melt to final product, with each batch accompanied by a Mill Test Certificate (MTC) certifying compliance to the required standard.

Our Manufacturing Capabilities: Delivering Precision and Customization

We understand that off-the-shelf sizes rarely meet the precise needs of complex engineering projects. Therefore, we specialize in providing custom-sized high-precision tubing to your exact specifications.

Key Capabilities Include:

-

Custom Outer Diameter (OD) and Inner Diameter (ID): We can produce tubes to meet specific dimensional requirements for your system layout.

-

Precise Wall Thickness: Control over wall thickness is critical for pressure rating and flow dynamics. We manufacture to tight wall thickness tolerances.

-

Multiple Lengths: Supplied in random, cut-to-length, or long single lengths to minimize welds in your installation.

-

Surface Finish: A variety of finishes are available, including annealed and pickled, mechanically polished, or bright annealed, to meet hygienic or process-specific needs.

Rigorous Quality Assurance and Testing

Every length of tubing undergoes a comprehensive battery of tests to ensure it meets the highest standards of quality and performance. Our quality assurance protocol includes:

-

Dimensional Inspection: Verification of OD, ID, wall thickness, and ovality using laser micrometers and ultrasonic testing.

-

Non-Destructive Testing (NDT): Eddy Current Testing (ECT) for surface defects, followed by hydrostatic or pneumatic pressure testing as required.

-

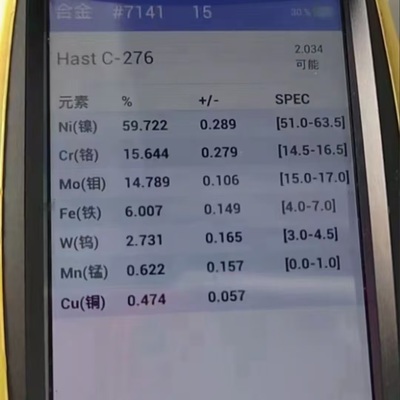

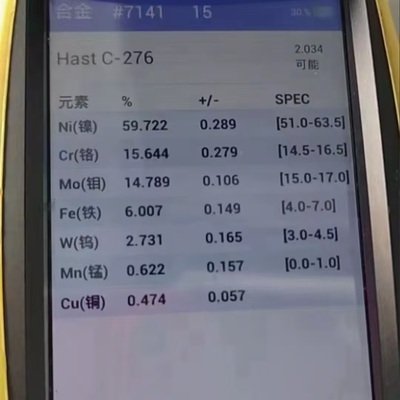

Chemical Analysis: Verification of alloy composition via spark spectrometry.

-

Mechanical Testing: Determination of tensile strength, yield strength, and elongation.

Critical Applications in Chemical Processing and Beyond

The combination of extreme corrosion resistance and high-precision manufacturing makes our C276 tubes indispensable in numerous sectors:

-

Chemical Processing Industry (CPI): Reactor coils, heat exchanger tubes, condenser tubes, and feeder lines handling hydrochloric acid, sulfuric acid, chlorine, and other aggressive catalysts.

-

Flue Gas Desulfurization (FGD) Systems: Absorber towers, mist eliminators, and ducting that resist the corrosive sulfites and chlorides in scrubber environments.

-

Pharmaceutical and Bio-Tech: Process piping and instrumentation tubing where ultra-high purity, cleanability, and resistance to corrosive sterilants are paramount.

-

Oil & Gas Production: Downhole instrumentation umbilicals, process piping, and components exposed to sour gas (H2S), CO2, and seawater.

-

Waste Incineration and Treatment: Handling aggressive combustion by-products and chemical waste streams.

Why Partner With Us for Your High-Precision Tubing Needs?

Choosing our high-precision Hastelloy C276 tubing means more than just purchasing a product; it means securing a reliable partnership. We offer:

-

Technical Expertise: Our team provides expert guidance on material selection and manufacturing standards.

-

Proven Quality: A fully documented supply chain and rigorous QA processes deliver guaranteed performance.

-

Customization Focus: We work with you to manufacture the exact component your application demands.

-

Global Supply Support: Reliable logistics to deliver your order on time, anywhere.

![]()

![]()

![]()

![]()