-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

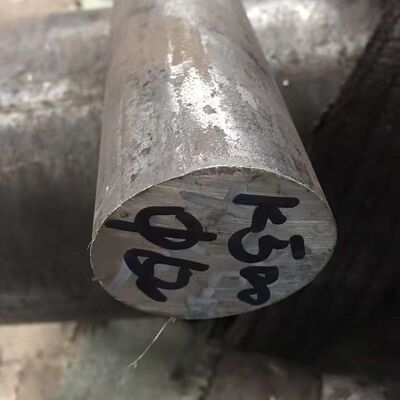

17-4PH (UNS S17400) Stainless Steel Round Bar Corrosion-Resistant High-Performance Alloy

| Herkunftsort | China |

|---|---|

| Markenname | Delta |

| Zertifizierung | ISO 9001 |

| Modellnummer | 17-4ph |

| Min Bestellmenge | 500 kg |

| Preis | 3.5 - 5.5 USD/Kg |

| Verpackung Informationen | Holzkiste oder wasserdichte Papierumhüllung |

| Lieferzeit | 5 - 10 Tage |

| Zahlungsbedingungen | T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 50 Tonne pro Monat |

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Produktname | 17-4PH Edelstahlstange | Durchmesser | 10 - 350mm |

|---|---|---|---|

| Länge | 6 m oder eine beliebige Länge als Anfrage schneiden | Oberfläche | schwarz oder polieren |

| Service | Schneiden | Standard | ASTM DIN GB EN |

| Andere Produkte | Runde Bar, Quadratriegel, flache Bar.ETC | Technik | Warmgewalzt |

17-4PH (UNS S17400) Stainless Steel Round Bar Corrosion-Resistant High-Performance Alloy

Products Specification

| Products Name | 17-4PH Stainless Steel Round Bar |

| Grade |

303,303Cu,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Products Diameter Range | φ3mm - φ350mm |

| Length | 6m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 50 kgs |

17-4PH (UNS S17400) Stainless Steel Round Bar: Corrosion-Resistant High-Performance Alloy

17-4PH stainless steel, also known by its UNS number S17400, is a precipitation-hardening steel that offers excellent corrosion resistance, high strength, and good mechanical properties. This high-performance alloy is particularly well-suited for demanding applications in industries like aerospace, chemical processing, and marine environments. As a round bar, 17-4PH stainless steel combines the versatility of a round shape with the superior properties of a premium alloy, making it an ideal choice for a wide range of applications.

Overview of 17-4PH Stainless Steel

17-4PH is a martensitic stainless steel that has been precipitation hardened to enhance its strength while maintaining good resistance to corrosion and oxidation. The alloy contains approximately 17% chromium, 4% nickel, and small amounts of other elements, including copper, which contributes to its unique properties.

The "PH" in 17-4PH stands for "precipitation hardening," which refers to the process that enables the steel to achieve high strength levels. In this process, the steel is heat-treated to promote the formation of precipitates (fine particles) that strengthen the material.

Key Properties of 17-4PH Stainless Steel

-

Corrosion Resistance:

17-4PH stainless steel offers superior corrosion resistance compared to other types of martensitic steels, making it ideal for use in harsh environments such as saltwater, chemicals, and high-temperature settings. It resists corrosion in both fresh and seawater environments, as well as against a wide range of industrial chemicals. -

High Strength:

This alloy boasts impressive mechanical properties, including high tensile strength and yield strength. It maintains excellent strength at both ambient and elevated temperatures, making it suitable for high-stress applications. -

Versatility:

The round bar form of 17-4PH stainless steel is commonly used in applications such as shafts, valves, fasteners, and various aerospace components. It can also be used in the manufacturing of heavy-duty industrial equipment and chemical processing tools. -

Good Fabricability:

Despite its high strength, 17-4PH stainless steel is easy to machine and can be welded using conventional techniques, which makes it a preferred material in industries that require precision machining and reliable fabrication. -

Toughness at Low Temperatures:

17-4PH retains its toughness and mechanical strength even in cryogenic temperatures, making it suitable for extreme temperature applications like those found in aerospace and marine industries.

Chemical Composition of 17-4PH Stainless Steel

The chemical composition of 17-4PH stainless steel is critical to its mechanical properties and performance. Below is the typical composition by weight:

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 15.0 - 17.5 |

| Nickel (Ni) | 3.0 - 5.0 |

| Copper (Cu) | 3.0 - 5.0 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Carbon (C) | 0.07 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Iron (Fe) | Balance |

Heat Treatment of 17-4PH Stainless Steel

The unique properties of 17-4PH stainless steel are achieved through a heat treatment process. The material undergoes a solution annealing process followed by aging at specific temperatures to achieve the desired hardness and strength. The heat treatment process allows manufacturers to tailor the alloy’s mechanical properties based on the specific requirements of the application.

-

Solution Annealing:

Solution annealing is performed at a temperature range of 1,900°F to 2,050°F (1,038°C to 1,121°C), followed by rapid cooling, typically through water quenching. -

Aging:

Aging is performed at a temperature of around 900°F to 1,150°F (482°C to 621°C) to precipitate strengthening particles that enhance the material's hardness and mechanical properties.

Mechanical Properties of 17-4PH Stainless Steel

Below are the mechanical properties of 17-4PH stainless steel when heat-treated to its precipitation-hardened condition:

| Property | Value |

|---|---|

| Tensile Strength (min) | 1,000 MPa (145 ksi) |

| Yield Strength (min) | 900 MPa (130 ksi) |

| Elongation in 2" (min) | 15% |

| Hardness (Rockwell B) | 93 - 98 HRC |

| Modulus of Elasticity | 200 GPa |

| Poisson’s Ratio | 0.30 |

These values are achieved after appropriate heat treatment and aging processes, giving 17-4PH stainless steel its high strength while still allowing for machining and forming.

Applications of 17-4PH Stainless Steel Round Bar

17-4PH stainless steel round bars are widely used in several industries due to their excellent strength and corrosion resistance. Some of the most common applications include:

-

Aerospace Components: The high strength and resistance to corrosion make 17-4PH stainless steel ideal for use in aerospace applications such as landing gears, engine parts, and structural components.

-

Chemical Processing: Due to its excellent resistance to a wide range of chemicals, it is used in valves, pumps, and other equipment used in chemical processing industries.

-

Marine: 17-4PH’s resistance to seawater and marine environments makes it a suitable material for marine hardware, including fasteners, propellers, and shafts.

-

Oil and Gas: This material is used in downhole drilling tools, wellhead equipment, and subsea hardware where strength and corrosion resistance are critical.

-

Nuclear: 17-4PH is used in nuclear power plants for components exposed to high radiation levels because of its strong resistance to radiation-induced damage.

Benefits of Using 17-4PH Stainless Steel Round Bars

-

High-Performance Alloy: The alloy combines high tensile strength and good corrosion resistance, which is essential in demanding applications where both durability and performance are critical.

-

Extended Durability: Its toughness and ability to resist wear and tear ensure that components made from 17-4PH last longer, reducing maintenance costs.

-

Cost-Effectiveness: While 17-4PH stainless steel is an advanced alloy, it often proves more cost-effective than other high-performance materials due to its ability to handle a variety of environmental challenges.

Conclusion

17-4PH stainless steel round bars are a top choice for industries requiring high strength, excellent corrosion resistance, and versatility in manufacturing. Their unique combination of mechanical properties, along with ease of fabrication, makes them suitable for a wide range of applications, from aerospace to chemical processing. This alloy’s ability to withstand extreme conditions and its adaptability to various processing methods ensure that it remains a preferred material for critical industrial and commercial components.

Whether you’re designing aerospace structures, marine hardware, or chemical processing equipment, 17-4PH stainless steel round bars offer a reliable solution to meet the most stringent performance requirements.