-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

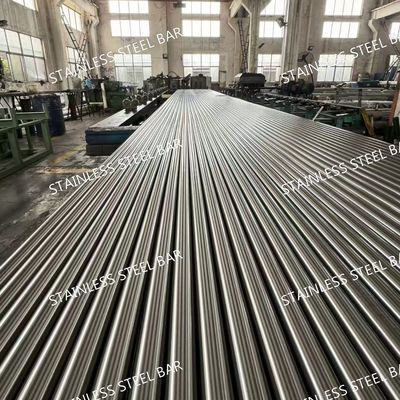

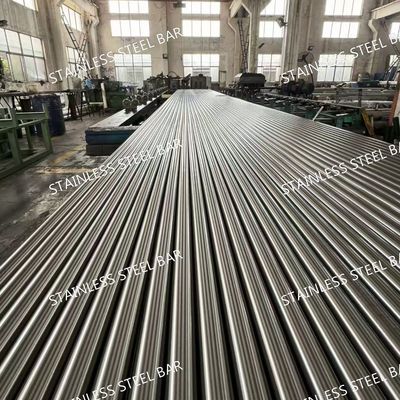

Durchmesser 3 - 150mm Legierung 321F Edelstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstah

| Herkunftsort | China |

|---|---|

| Markenname | Delta |

| Zertifizierung | ISO 9001 |

| Modellnummer | 321F |

| Min Bestellmenge | 500 kg |

| Preis | 2.4-3.5 USD/Kg |

| Verpackung Informationen | Holzkiste oder wasserdichte Papierumhüllung |

| Lieferzeit | 5 - 10 Tage |

| Zahlungsbedingungen | T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 50 Tonne pro Monat |

| Produktname | Stange aus 321F-Edelstahl | Durchmesser | 10 - 350mm |

|---|---|---|---|

| Länge | 6 m oder eine beliebige Länge als Anfrage schneiden | Oberfläche | Beim Einlegen oder Brennen |

| Service | Schneiden | Standard | ASTM DIN GB EN |

| Andere Produkte | Runde Bar, Quadratriegel, flache Bar.ETC | Technik | Heiß gerollt |

| Hervorheben | Stahlstahlbarren aus Legierung 321F,Schleifbarren für die Präzisionsschleiferei,Stäbchen aus Edelstahl mit geringer Toleranz |

||

Durchmesser 3 - 150mm Legierung 321F Edelstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlsta

Produktspezifikation

| Produktbezeichnung | 321F Runde Stange aus Edelstahl |

| Zulassung |

303,304,304L,309S, 310S, 310H, 316L, 316Ti, 316H, 317L321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800800H,825,926. usw. |

| Produkte Durchmesserbereich | φ3mm - φ350mm |

| Länge | 6 m/Stück oder auf Wunsch in beliebiger Länge geschnitten |

| Oberfläche | Bearbeitung mit Brei, helle Bearbeitung |

| Standards | ASTM JIS, GB, DIN EN |

| Dienstleistungen | Schneiden |

| Andere Formen | Quadratisch, flach, sechseckig, rund usw. |

| Ladehafen | Hafen von Shanghai |

| MOQ | 50 kg |

Durchmesser 3 - 150mm Legierung 321F Edelstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlstahlsta

Einführung in den Durchmesser 3 - 150 mm Legierung 321F aus Edelstahl

mit einer Breite von mehr als 0,05 mm,3 mm bis 150 mmDiese spezielle Qualität von Edelstahl, 321F, ist für die Herstellung vonist eine mit Titan stabilisierte Variante des weit verbreiteten Edelstahls Typ 304, entwickelt, um eine verbesserte Beständigkeit gegen intergranulare Korrosion, Oxidation und Spannungskorrosion zu bieten.

Diesemit einer Breite von nicht mehr als 20 mm,Sie werden so verarbeitet, dass sehr enge Toleranzen erreicht werden, was sie für hochpräzise Anwendungen in Industriezweigen wie Luft- und Raumfahrt, chemische Verarbeitung, Stromerzeugung und Lebensmittelverarbeitung ideal macht.Die feine Oberflächenausführung und die geringen Toleranzen machen diese Stangen zu einer ausgezeichneten Wahl für sowohl strukturelle als auch dekorative Zwecke.

In dieser Produktübersicht werden wir die Eigenschaften, Anwendungen, Spezifikationen und Vorteile vonDurchmesser 3 - 150 mm Legierung 321F Edelstahlstangen, mit Schwerpunkt auf Präzisionsschleifen und geringen Toleranzklassen.

Legierung 321F Zusammensetzung aus Edelstahl

Das Hauptmerkmal von321F Edelstahlist seine Titanstabilisierung, die die Bildung von Chromcarbid an den Korngrenzen beim Schweißen und bei hoher Temperatur verhindert.Dies stellt sicher, dass die Legierung gegen intergranulare Korrosion resistent bleibt, die besonders in Industriezweigen nützlich ist, in denen hochtemperaturspezifische Leistung und Schweißfähigkeit erforderlich sind.

Typische chemische Zusammensetzung von Legierung 321F Edelstahl:

| Elemente | Inhalt |

|---|---|

| Chrom (Cr) | 17.0 - 19,0% |

| Nickel (Ni) | 9.0 - 12,0% |

| Titanium (Ti) | 5xC Min. |

| Mangan (Mn) | 20,0% max. |

| Silizium (Si) | 10,0% max. |

| Kohlenstoff (C) | 0.08% max. |

| Fosfor (P) | 00,045% max. |

| Schwefel (S) | 0.030% max. |

Die...Titanium (Ti)Der Gehalt an Legierung 321F spielt eine entscheidende Rolle bei der Stabilisierung der Struktur des Edelstahls und bei der Verhinderung der Bildung von schädlichen Chromkarbiden.Dies macht 321F eine ausgezeichnete Wahl für Anwendungen, wo Schweißen und Wärmebeständigkeit sind kritisch.

Hauptmerkmale von Stangen mit Durchmesser 3 - 150 mm aus Edelstahl aus Legierung 321F

Mechanische Eigenschaften

Die Edelstahlbarren aus Legierung 321F weisen ausgezeichnete mechanische Eigenschaften auf, was sie ideal für Anwendungen macht, bei denen Festigkeit und Haltbarkeit entscheidend sind.Einige der wichtigsten mechanischen Eigenschaften von 321F-Edelstahlstangen sind::

| Eigentum | Wert |

|---|---|

| Zugfestigkeit | 515 - 690 MPa (75.000 ∼ 100.000 psi) |

| Leistungsstärke | 205 - 350 MPa (30.000 ∼ 50.000 psi) |

| Verlängerung | 40% min (in 50 mm) |

| Härte | Rockwell B (HRB) maximal 90 |

| Modul der Elastizität | 200 GPa (29 x 103 ksi) |

Diese Werte deuten darauf hin, dass die 321F-Edelstahlstangen eine starke Fähigkeit haben, mechanischen Spannungen und Verformungen standzuhalten, was sie für Hochleistungstechnikanwendungen geeignet macht.Die...VerlängerungundLeistungsstärkeDiese Werte deuten auf eine gute Flexibilität ohne Beeinträchtigung der Festigkeit hin.

Wärme- und Korrosionsbeständigkeit

321F-Edelstahlstangen sind so konzipiert, dass sie extremen Temperaturen standhalten und Korrosion in rauen Umgebungen widerstehen.

| Eigentum | Wert |

|---|---|

| Höchstbetriebstemperatur | 870°C (1600°F) |

| Wärmeleitfähigkeit | 15.1 W/m·K bei 100°C |

| Spezifische Wärmekapazität | 500 J/kg·K bei 25°C |

| Koeffizient der thermischen Ausdehnung | 17.3 μm/m·K bei 20 ̊100°C |

-

Korrosionsbeständigkeit: 321F Edelstahl bietet eine überlegene Beständigkeit gegen Oxidation und Korrosion zwischen den Körnern, auch bei hohen Temperaturen.Luft- und Raumfahrt, Stromerzeugung, undchemische Verarbeitungsindustrie.

-

Oxidationsbeständigkeit: Das Material kann bei Temperaturen bis zu 870°C (1600°F) der Oxidation standhalten und eignet sich somit für den Einsatz in Abgassystemen, Motorteilen und hochtemperaturen Rohrleitungen.

Schweißbarkeit

Aufgrund seiner Titanstabilisierung,321F EdelstahlEs verhindert, dass an den Korngrenzen Karbid abfällt, was zuSensibilisierung(intergranulare Korrosion), wodurch sichergestellt wird, daß das Material auch nach dem Schweißen seine hochtemperatur- und korrosionsbeständigen Eigenschaften behält.

Präzisionsschleifen und kleine Toleranzmerkmale

Einer der herausragenden Merkmale dieserDurchmesser 3 - 150 mm EdelstahlstangenDie Stäbe werden strengen Schleifverfahren unterzogen, um sicherzustellen, dass sie strengen Toleranzen entsprechen,die in hochpräzisen Anwendungen von entscheidender Bedeutung sind, bei denen leichte Abweichungen die Endleistung der Komponente beeinträchtigen können.

Toleranzen für das Präzisionsschleifen

| Toleranzklasse | H6 | H7 | H8 | H9 |

|---|---|---|---|---|

| Toleranz | ± 0,010 mm | ± 0,020 mm | ±0,030 mm | ±0,050 mm |

-

H6 Toleranz: Diese Toleranzklasse eignet sich für Anwendungen mit hoher Präzision, bei denen exakte Messungen von entscheidender Bedeutung sind.

-

H7 Toleranz: Häufig in mechanischen Bauteilen verwendet, bei denen eine moderate Präzision erforderlich ist.

-

H8 und H9 Toleranzen: Diese sind entspannter und können in allgemeinen industriellen Anwendungen eingesetzt werden, wo geringe Abmessungsunterschiede die Funktion nicht beeinträchtigen.

Das Präzisionsschleifen sorgt dafür, dass jeder Balken gerade ist, eine gleichbleibende Oberflächenveredelung und Glatzheit aufweist, wodurch er leicht bearbeitet oder in Baugruppen integriert werden kann.

Anwendungen von Stäben mit Durchmesser 3 - 150 mm aus Legierung 321F aus Edelstahl

Die Edelstahlbarren aus Legierung 321F eignen sich für eine Vielzahl von Anwendungen, dieFestigkeit, Langlebigkeit, undKorrosionsbeständigkeitEinige der gängigsten Industriezweige und Anwendungen sind:

Luft- und Raumfahrt

-

Motorkomponenten (z. B. Turbinenblätter, Abgassysteme)

-

Hochtemperaturkonstruktionsbauteile

-

Luftfahrzeugrahmen und -stützen, die extremen Bedingungen ausgesetzt sind

Chemische und petrochemische Verarbeitung

-

Heizwechsler

-

ZisternenundFischereifahrzeugefür ätzende Flüssigkeiten

-

Rohrleitungenfür raue Umgebungen

-

ReaktorenundDruckbehälterfür Hochtemperatur- und ätzende Umgebungen

Stromerzeugung

-

Teile für Turbinenundmit einer Leistung von mehr als 50 kWfür thermische Anlagen

-

HeizwechslerundKühlsysteme

-

AbgassystemeundVentilemit hohem Druck und hoher Temperatur ausgesetzt

Nahrungsmittel- und pharmazeutische Verarbeitung

-

Teile von Maschinen, bei denenHygieneundKorrosionsbeständigkeitsind wesentlich

-

Speichertank,Rohre, undWärmetauscherReinigungschemikalien und hohen Temperaturen ausgesetzt

Vorteile von Stangen aus Edelstahl mit Durchmesser 3 - 150 mm

-

Hochtemperaturbeständigkeit: Die Leistungsfähigkeit der Legierung bei Temperaturen bis zu 870°C macht sie für extreme Umgebungen geeignet.

-

Korrosionsbeständigkeit: Aussergewöhnliche Beständigkeit gegen Korrosion und Oxidation bei hohen Temperaturen.

-

Schweißbarkeit: Die Titanaufnahme sorgt für eine überlegene Schweißfähigkeit, ohne die Eigenschaften des Materials zu beeinträchtigen.

-

Präzisionsschleifen: Die Stäbe werden für enge Toleranzen (H6, H7, H8, H9) hergestellt, um die für anspruchsvolle Anwendungen erforderlichen genauen Spezifikationen zu erfüllen.

-

Stärke und Langlebigkeit: Hohe mechanische Festigkeit und Zähigkeit gewährleisten eine lange Lebensdauer und minimale Wartungskosten.

-

Vielseitigkeit: Ideal für eine Vielzahl von Branchen, darunter Luft- und Raumfahrt, chemische Verarbeitung, Lebensmittel und Pharma und Stromerzeugung.

Schlussfolgerung

Die...Durchmesser 3 - 150 mm Legierung 321F Edelstahlstangemit hoher Präzisionsschleiffähigkeit und geringer Toleranz ist ein sehr vielseitiges Material für Hochleistungsanwendungen.und die Fähigkeit, extremen Temperaturen standzuhalten, ist die bevorzugte Wahl in Branchen, in denen Zuverlässigkeit und Haltbarkeit von größter Bedeutung sind.

Egal, ob Sie in der Luftfahrt, der Petrochemie oder der Stromerzeugung tätig sind, diese Edelstahlstangen können Ihren Anforderungen an Präzision und Leistung gerecht werden.Die glatte Oberfläche macht sie ideal für eine Vielzahl von Anwendungen, von Strukturbauteilen bis hin zu hochpräzisen Maschinen.

![]()

![]()

![]()

![]()