-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

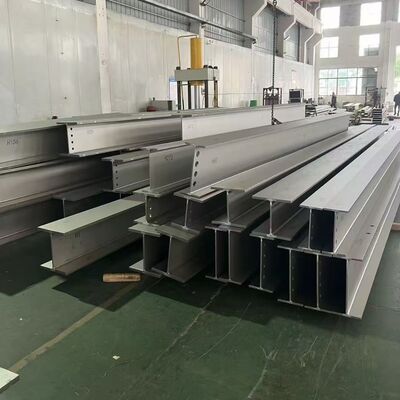

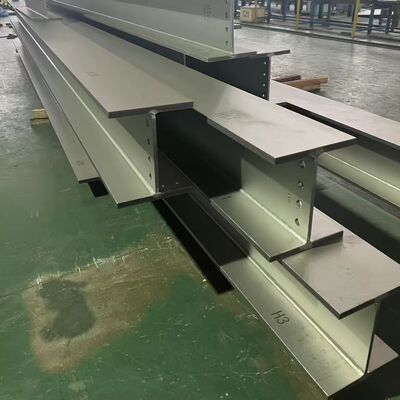

Pièces en acier inoxydable soudées de précision à la section H pour la construction industrielle

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | DELTA |

| Certification | ISO |

| Numéro de modèle | 304 316L 321 310S |

| Quantité de commande min | 1 tonne |

| Prix | 2400 - 3500 USD/Ton |

| Détails d'emballage | Emballage standard pour l'exportation |

| Délai de livraison | 5 - 12 jours en fonction de la quantité |

| Conditions de paiement | LC, T/T, Western Union |

| Capacité d'approvisionnement | 5Ton par semaine |

| Nom des produits | Poutre en double T d'acier inoxydable | TAILLE | 100*100 - 400*400mm ou coutume comme demande |

|---|---|---|---|

| Grade | 304 316L 321 310S.etc. | Longueur | 6m ou comme demande |

| Finition | marinage | Autres produits | Angle, la Manche, plat, hexagonale |

| Standard | ASTM EN F | Taper | Soudé |

| Mettre en évidence | Pièces en acier inoxydable soudées de précision,Faisceaux à section H pour la construction industrielle,poutres H en acier inoxydable avec garantie |

||

Pièces en acier inoxydable soudées de précision à la section H pour la construction industrielle

Spécification des produits

| Nom du produit | Faisceau H en acier inoxydable | |||

| Épaisseur | 6.0 à 40.0 mm | |||

| Longueur | 6m/pcs ou Coupe sur mesure selon la demande | |||

| Surface | Je ne veux pas.1 | |||

| Technologie | Soudés ou laminés à chaud | |||

| Grade d'acier | 304Pour les appareils à commande numérique:316,316Ti,317,317L,321,347Pour les appareils de traitement des eaux usées:201,202,409,410,420,430. | |||

| La norme | Pour les produits de base, la valeur de l'échantillon doit être supérieure ou égale à: | |||

| Le test | Test de traction, test de rendement, test d'allongement, test de flexion à froid, dureté, test de corrosion des cristaux, test de composition chimique. | |||

| Emballage | papier étanche et cadre en bois | |||

| Nombre de pièces | 1 tonne | |||

| Machinerie | Coupe, forage | |||

Pièces en acier inoxydable soudées de précision à la section H pour la construction industrielle

Conçues pour être résistantes, durables et fiables dans les environnements les plus exigeants, les poutres en H en acier inoxydable soudés avec précision sont une pierre angulaire de la construction industrielle moderne.Combinaison de techniques de fabrication avancées avec des alliages d'acier inoxydable de haute performance, tels que le grade 304, 316L, et 310S· ces éléments structurels offrent une capacité de charge exceptionnelle, une résistance à la corrosion et une précision dimensionnelle adaptée aux applications lourdes.

Pourquoi la soudure de précision est importante

Contrairement aux faisceaux H traditionnels laminés à chaud,les sections H soudéses de précision sont fabriquées à partir de plaques d'acier inoxydable de haute qualité à l'aide de procédés de soudage automatisés tels que le soudage à l'arc submergé (SAW) ou le soudage hybride au laserCette méthode garantit:

- Tolérances dimensionnelles plus serrées (± 1 ‰ 2 mm sur la hauteur/la largeur de la bride)

- Pénétration uniforme de la soudure avec une distorsion minimale

- Sections transversales personnalisées non limitées par les capacités de laminage des moulins

- Optimisation du rapport poids/résistance, réduction des déchets de matériaux

- Finitions de surface lisses, idéales pour des applications hygiéniques ou esthétiques

Ces avantages font des poutres H soudéses de précision le choix préféré pour les projets où les performances, la longévité et les spécifications exactes ne sont pas négociables.

Grades de matériau: performance à première vue

| Caractéristique | Grade 304 | Grade 316L | Grade 310S |

|---|---|---|---|

| Éléments d'alliage essentiels | 18% Cr, 8% Ni | 1618% Cr, 1014% Ni, 23% Mo | 25% Cr, 20% Ni |

| Résistance à la corrosion | Bon dans les environnements urbains et chimiques doux. | Excellent dans les milieux marins, acides et riches en chlorure | Supérieure à l'oxydation à haute température (jusqu'à 1150°C) |

| Saldabilité | C' est excellent. | Excellent (faible teneur en carbone empêche la sensibilisation) | Bon (exige un contrôle avant/après la chaleur) |

| Cas d'utilisation typiques | Fabricants de transformation alimentaire, salles blanches, cadres architecturaux | Plateformes offshore, réacteurs chimiques, usines de dessalement | Soutiens de fours, systèmes d'échappement, équipements de traitement thermique |

| Résistance au rendement (min) | 205 MPa | 170 MPa | 205 MPa |

Conseils professionnels: choisissez 316L pour l'exposition côtière ou chimique; choisissez 310S pour les opérations supérieures à 900 °C.

Spécifications techniques

-

Conformité aux normes:

- ASTM A276 / A484 (États-Unis)

- Pour les appareils électroniques

- Les États membres doivent communiquer à l'autorité compétente des États membres les informations suivantes:

- Pour les appareils électroniques

-

Dimensions disponibles:

- La hauteur (H): 100 mm 1000 mm

- Largeur de la bride (B): 50 mm ∼ 500 mm

- Épaisseur de la toile (tw): 4 mm 30 mm

- L'épaisseur de la bride (tf): 5 mm ∼ 35 mm

- Longueur standard: 6 m, 9 m, 12 m (coupe personnalisée disponible)

-

Tolérances (par GB/T 33814):

- La hauteur et la largeur de la bride: ±2,0 mm

- Épaisseur: ±0,5 mm

- Légèreté: ≤ 1,5 mm par mètre

-

Finitions de surface:

- Pâte en épinards et passivée (standard)

- 2B, BA, n° 4 (brossé) ou vernis miroir (facultatif)

Applications industrielles

-

Les usines chimiques et pétrochimiques

Les poutres H fabriquées en 316L résistent à la corrosion des crevasses et des fissures par les acides, les solvants et les atmosphères salées, ce qui est essentiel pour les supports de tuyauterie, les structures de support et les cadres de réacteurs. -

Infrastructure maritime et offshore

Résistant à l'humidité et aux saumons constants, utilisé dans les grues, les passerelles et les systèmes de soutien sous-marins. -

Traitement à haute température

Les sections en H 310S maintiennent l'intégrité structurelle dans les fours, les incinérateurs et les fours de traitement thermique, même sous contrainte thermique cyclique. -

Fabrication pharmaceutique et alimentaire

Les surfaces lisses et non poreuses empêchent la croissance bactérienne, facilement nettoyées et conformes aux normes FDA et GMP. -

Édifices industriels lourds

Les toits d'usines, les pistes des grues et les cadres résistants aux tremblements de terre bénéficient de la grande résistance et de l'entretien réduit des poutres en H inoxydable.

Protocoles d'assurance qualité et d'essais

Chaque faisceau est soumis à une vérification en plusieurs étapes:

- Analyse spectrométrique pour déterminer la composition précise des alliages

- Test de traction, de flexion et d'impact selon les normes ASTM/EN

- Épreuves non destructives: inspection par ultrasons (UT) ou radiographique (RT) des soudures critiques

- Épreuve par pulvérisation saline (ASTM B117) pour la validation de la corrosion

- Scanner laser dimensionnel pour une précision géométrique

La documentation complète comprend les rapports d'essais en usine (MTR), les certificats EN 10204 3.1 et les spécifications de procédure de soudage (WPS/PQR).

Durabilité et valeur du cycle de vie

Les poutres H en acier inoxydable sont 100% recyclables et ne nécessitent aucune peinture ou revêtement, ce qui élimine les émissions de COV et les temps d'arrêt de maintenance.Leur durée de vie est souvent supérieure à 50 ans, même dans des environnements agressifs, offrant un retour sur investissement inégalé par rapport aux alternatives en acier au carbone.

Guide de commande

Pour demander un devis ou une consultation technique, veuillez fournir:

- Grade souhaité (304 / 316L / 310S)

- Les dimensions de la section transversale (H × B × tw × tf)

- Longueur et quantité requises

- Finition de surface et besoins de certification

- Exigences particulières (par exemple, niveau de NDT, emballage à l'exportation)

Nous soutenons la logistique mondiale, la livraison juste à temps et les modèles de CAO compatibles BIM pour une intégration transparente dans votre flux de travail de conception.

Conclusion

Dans la construction industrielle, l'échec n'est pas une option: les poutres en H en acier inoxydable soudées de précision offrent la fusion parfaite de l'excellence de l'ingénierie et de la science des matériaux, assurant la sécurité.la durabilitéQu'elles soient exposées à des produits chimiques corrosifs, à une chaleur extrême ou à l'air implacable de l'océan, ces poutres restent fermes là où d'autres se dégradent.

faisceau H en acier inoxydable soudé de précision, faisceaux H à section industrielle, acier structurel 304 316L 310S, profil H résistant à la corrosion, faisceau H en acier inoxydable sur mesure, section H soudée à haute résistance,Pièces de bois en acier inoxydable pour usines chimiques.

![]()

![]()

![]()

![]()