-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

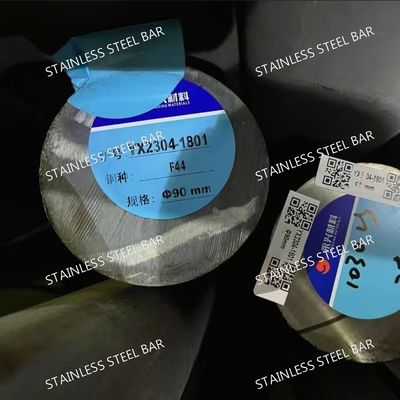

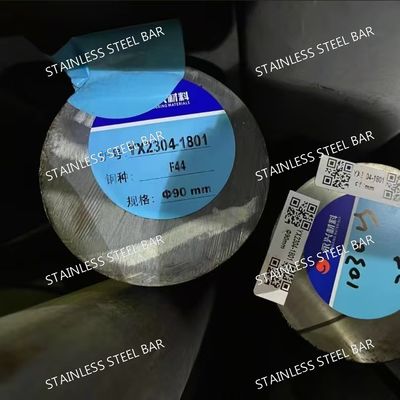

Premium UNS N08020 Alloy Steel Bar Alloy 20 High-Performance Stainless Steel Rod

| Lieu d'origine | CHINE |

|---|---|

| Nom de marque | Delta |

| Certification | ISO 9001 |

| Numéro de modèle | N08020, alliage 20 |

| Quantité de commande min | 500 kg |

| Prix | 2000-3200 USD/Ton |

| Détails d'emballage | boîte en bois ou enveloppe en papier résistant à l'eau |

| Délai de livraison | 5 - 10 jours |

| Conditions de paiement | T / T, Western Union |

| Capacité d'approvisionnement | 50 tonnes par mois |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Nom de produits | Barres en acier inoxydable | Diamètre | 10 - 350mm |

|---|---|---|---|

| Longueur | 6m ou couper n'importe quelle longueur comme demande | Surface | Délicieux ou brillant |

| Service | COUPE | Standard | Astm din gb en |

| Autres produits | barre ronde, barre carrée, barre plate.etc | Technique | Chaud roulé |

| Mettre en évidence | UNS N08020 alloy steel bar,Alloy 20 stainless steel rod,high-performance stainless steel bar |

||

Premium UNS N08020 Alloy Steel Bar Alloy 20 High-Performance Stainless Steel Rod

Products Specification

| Products Name | Stainless Steel Round Bar |

| Grade |

304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,C276,600,601,625,718,800,800H,825,926.etc |

| Products Diameter Range | φ10mm - φ350mm |

| Length | 6m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 500 kgs |

Premium UNS N08020 Alloy Steel Bar - Alloy 20 High-Performance Stainless Steel Rod

UNS N08020, commonly referred to as Alloy 20, is a premium, high-performance stainless steel alloy designed for superior corrosion resistance and exceptional mechanical properties in harsh environments. Known for its outstanding resistance to sulfuric acid and other aggressive chemicals, UNS N08020 stainless steel bar is a preferred material in industries where chemical processing, high-temperature resistance, and durability are paramount. With its high strength and resistance to oxidation, Alloy 20 is widely used in applications such as chemical processing, food and beverage manufacturing, marine, and pharmaceuticals.

In this article, we will explore the key features, advantages, manufacturing processes, and applications of UNS N08020 stainless steel bars to help you understand why this alloy is an optimal choice for various industries.

What is UNS N08020 Alloy Steel?

UNS N08020 is a high-nickel alloy designed to provide excellent resistance to a wide range of corrosive environments. Alloy 20 has a high concentration of nickel (approximately 30-38%), along with chromium and molybdenum, which contribute to its superior corrosion resistance. It is highly resistant to pitting, crevice corrosion, and stress corrosion cracking, making it particularly useful in environments where other stainless steels would fail.

UNS N08020 is commonly referred to as Alloy 20 due to its high nickel content, which provides excellent protection against aggressive chemicals, including sulfuric acid and phosphoric acid. Additionally, the alloy's resistance to chloride-induced stress corrosion cracking makes it a preferred material for environments with high chloride concentrations, such as seawater or brine.

This material is often used in applications where resistance to corrosion, high strength, and ease of fabrication are required. Alloy 20 is an ideal choice for industries that demand both superior mechanical performance and excellent long-term resistance to aggressive environments.

Key Features of UNS N08020 Stainless Steel Bar

-

Exceptional Corrosion Resistance: One of the standout features of UNS N08020 is its exceptional resistance to corrosion. Alloy 20’s resistance to sulfuric acid, phosphoric acid, and chloride-induced stress corrosion cracking makes it an excellent material for harsh chemical environments.

-

High-Temperature Stability: UNS N08020 offers superior strength and durability at elevated temperatures, typically up to around 1000°F (537°C), making it ideal for use in high-temperature applications.

-

Excellent Mechanical Properties: Alloy 20 retains good mechanical properties, including tensile strength, yield strength, and toughness. These properties make it resistant to mechanical stress and wear in industrial settings.

-

Ease of Fabrication and Welding: UNS N08020 is known for its excellent weldability and formability. It can be easily welded using conventional welding methods and can be formed into a wide range of complex shapes and sizes without losing its strength or corrosion resistance.

-

Resistant to Pitting and Crevice Corrosion: The alloy’s resistance to pitting and crevice corrosion, particularly in chloride-rich environments, makes it ideal for marine, chemical processing, and other high-stress applications.

-

Food Grade Compatibility: Due to its high resistance to corrosion, UNS N08020 is also suitable for the food and beverage industry, where cleanliness, hygiene, and corrosion resistance are essential.

Chemical Composition of UNS N08020 Stainless Steel

The unique combination of elements in UNS N08020 gives it its superior resistance to corrosion and high-temperature performance. The typical chemical composition of Alloy 20 includes:

-

Nickel (Ni): 30-38%

-

Chromium (Cr): 19-21%

-

Iron (Fe): Balance

-

Molybdenum (Mo): 2-3%

-

Copper (Cu): 3-4%

-

Manganese (Mn): ≤ 2%

-

Silicon (Si): ≤ 1%

-

Carbon (C): ≤ 0.05%

-

Phosphorus (P): ≤ 0.04%

-

Sulfur (S): ≤ 0.03%

This composition enables UNS N08020 stainless steel bars to excel in corrosive environments while maintaining their mechanical integrity.

Manufacturing Process of UNS N08020 Stainless Steel Bar

The production of UNS N08020 stainless steel bars involves several key steps, including casting, hot rolling, cold working, and heat treatment, to ensure that the material meets the necessary specifications and standards.

1. Casting:

UNS N08020 starts its manufacturing process as molten metal, which is poured into molds to form billets or ingots. This ensures uniformity in the alloy’s chemical composition, which is crucial for achieving the desired corrosion resistance and mechanical properties.

2. Hot Rolling:

After casting, the billets are heated to high temperatures and passed through rollers to form round bars or rods. This process allows the material to take shape, and it also enhances the material’s mechanical properties by refining its grain structure.

3. Cold Working:

Once the bars are hot-rolled, they may undergo cold working processes like drawing, grinding, or machining to achieve precise dimensions and surface finishes. Cold working enhances the material’s surface quality and can further refine its strength and hardness.

4. Heat Treatment:

To optimize the material's mechanical properties, heat treatment such as annealing or solution treatment is often applied. This process helps relieve internal stresses in the alloy and ensures it meets the required standards for tensile strength, yield strength, and other mechanical properties.

Cutting UNS N08020 Stainless Steel Bar to Any Length

One of the key advantages of UNS N08020 stainless steel bars is their flexibility in customization. These bars can be cut to any length, allowing for precise matching of project requirements. Whether you need standard lengths or highly customized sizes, this alloy can be adapted to meet the specifications of your application.

-

Precision Cutting: Advanced cutting technologies such as saw cutting, waterjet cutting, and laser cutting ensure that UNS N08020 bars are cut to exact lengths with minimal waste. This ensures efficiency and cost-effectiveness.

-

Custom Lengths for Specific Applications: Whether you need a specific length for high-performance components or custom rods for unique designs, the ability to tailor the size of the bars ensures the perfect fit for your project.

-

Cost-Efficient Solutions: Cutting bars to the precise length required minimizes material waste and reduces the need for additional stock. This not only saves on material costs but also ensures a more sustainable approach to manufacturing.

Applications of UNS N08020 Stainless Steel Bar

UNS N08020 stainless steel bars are used across a wide range of industries due to their excellent corrosion resistance, high strength, and resistance to high temperatures. Below are some of the most common applications of Alloy 20 in various industries:

1. Chemical Processing Industry

Alloy 20 is most widely used in chemical processing industries for applications involving aggressive chemicals such as sulfuric acid, hydrochloric acid, and phosphoric acid. It is commonly used in heat exchangers, reactors, pipes, and tanks that process corrosive chemicals.

2. Pharmaceutical Industry

In pharmaceutical manufacturing, Alloy 20 is used for the fabrication of equipment such as mixers, vessels, and piping systems. The alloy’s resistance to corrosion and its ability to maintain its structural integrity at high temperatures make it ideal for pharmaceutical applications where cleanliness and material safety are critical.

3. Food and Beverage Industry

UNS N08020 is also suitable for food and beverage applications due to its resistance to acidic substances and its hygienic properties. It is commonly used in food processing equipment, including storage tanks, mixing vessels, and piping systems that come into contact with food products.

4. Marine Industry

The marine industry relies on UNS N08020 stainless steel for equipment that is exposed to seawater and marine environments. The alloy’s resistance to saltwater corrosion makes it a suitable material for marine structures, propellers, and offshore rigs.

5. Aerospace and High-Temperature Applications

Alloy 20 is also used in aerospace applications where high strength and temperature resistance are required. It is used in turbine engines, exhaust systems, and other components that must endure extreme heat and mechanical stress while resisting corrosion.

6. Oil and Gas Industry

In the oil and gas sector, UNS N08020 is used for manufacturing equipment exposed to harsh chemicals and extreme temperatures, such as pumps, valves, and pressure vessels. Its resistance to both corrosion and high temperatures makes it suitable for offshore and onshore oil drilling operations.

Benefits of Using UNS N08020 Stainless Steel Bar

-

Corrosion Resistance: UNS N08020 offers superior protection against corrosion, especially in environments with aggressive chemicals such as acids, chlorides, and sulfuric compounds.

-

High-Temperature Resistance: The alloy’s ability to retain strength and performance at high temperatures makes it suitable for demanding industrial applications, particularly in aerospace, chemical processing, and power generation.

-

Long-Term Durability: UNS N08020’s resistance to stress corrosion cracking and pitting ensures that parts made from this material have a long lifespan, reducing maintenance and replacement costs.

-

Fabricability and Weldability: Alloy 20 is easy to weld and fabricate, making it an ideal choice for creating custom components that meet specific design requirements.

![]()

![]()

![]()

![]()