-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

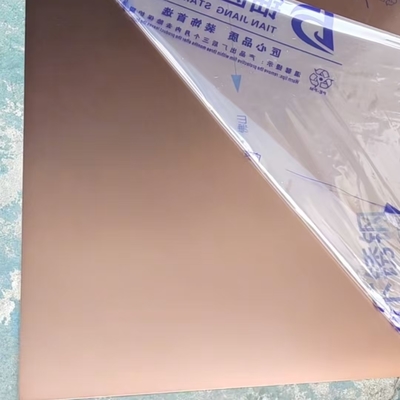

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

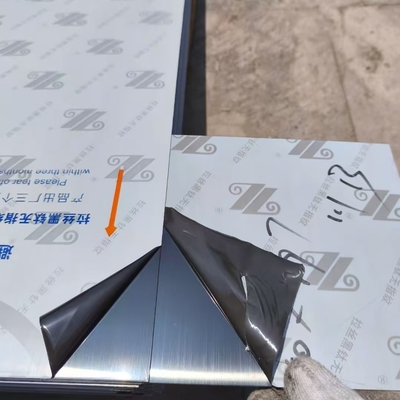

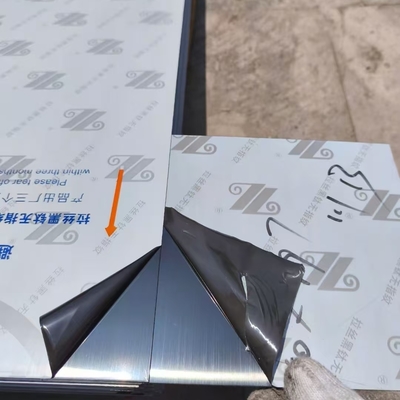

Plaque d'acier inoxydable miroir noir 0,8 mm 1,0 mm 1,2 mm 4 pieds * 8 pieds sablage, finition mate

| Lieu d'origine | CHINE |

|---|---|

| Nom de marque | HONGWANG |

| Certification | ISO |

| Numéro de modèle | Sus304 |

| Quantité de commande min | 1 tonne |

| Prix | 2100 - 3200 USD/Ton |

| Détails d'emballage | Emballage standard pour l'exportation |

| Délai de livraison | 5 - 12 jours en fonction de la quantité |

| Conditions de paiement | L / C, T / T, Western Union |

| Capacité d'approvisionnement | 20 tonnes par semaine |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Produits | feuille d'acier inoxydable | Grade | Sus304 |

|---|---|---|---|

| Épaisseur | 0,4 - 1,5 mm | Technologie | À froid roulé |

| Largeur | 1000mm 1219mm 1500mm ou coutumes comme demande | Surface | miroir noir |

| Standard | EN DIN D'ASTM GIGAOCTET JIS | MOQ | 1 tonne |

| Mettre en évidence | Feuille d'acier inoxydable de Black Mirror,finition mate pour le sablage de tôles d'acier inoxydable,Plaque d'acier inoxydable de 4 pieds x 8 pieds |

||

Tôle d'acier inoxydable miroir noir 0,8 mm 1,0 mm 1,2 mm 4 pieds * 8 pieds Sablage au jet, finition mate

Spécifications des produits

| Nom des produits | Tôle d'acier inoxydable miroir noir |

| Qualité | SUS201, SUS304, SUS430 |

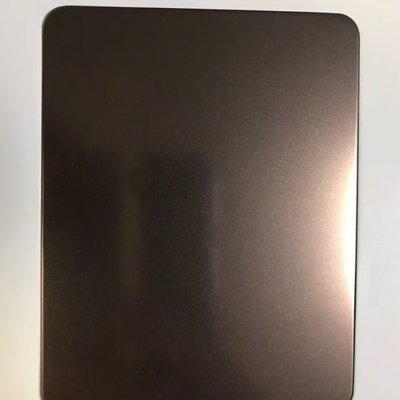

| Surface | 2B, BA, Miroir, NO.4, Hairline, Miroir doré, Hairline doré, Bronze, Noir, Bleu, Or Rose |

| Finition | Impression anti-doigts et film laser |

| Largeur | 1000 1219 mm 1500 mm |

| Longueur | 1000-3000 mm |

| Épaisseur | 0,40 mm – 1,50 mm |

Tôle d'acier inoxydable miroir noir 0,8 mm 1,0 mm 1,2 mm 4 pieds * 8 pieds Sablage au jet, finition mate

1. Introduction aux tôles d'acier inoxydable miroir noir

2. Processus de production

- Préparation du matériau de base : Commencez par des bobines ou des plaques d'acier inoxydable de haute qualité (par exemple, 304, 316L). Le métal de base est d'abord nettoyé par dégraissage et décapage pour éliminer l'huile, la rouille ou les couches d'oxyde—cette étape est essentielle pour assurer une adhérence uniforme des revêtements ultérieurs.

- Polissage miroir : La surface en acier inoxydable nettoyée est polie à l'aide de matériaux abrasifs (tels que des tampons diamantés) et d'équipements de polissage avancés. Ce processus crée une surface lisse et réfléchissante avec une brillance élevée (généralement 8K ou plus, ce qui signifie qu'elle réfléchit jusqu'à 80 % de la lumière, comparable à un miroir en verre).

- Traitement de coloration noire : Deux méthodes principales sont utilisées pour obtenir la finition noire, assurant à la fois la solidité des couleurs et la résistance à la corrosion :

- PVD (Physical Vapor Deposition) : Sous vide poussé et température contrôlée, des composés métalliques (par exemple, nitrure de titane, nitrure de chrome) sont vaporisés et déposés sur la surface polie en acier inoxydable. Cela forme un film noir mince (à l'échelle nanométrique) qui se lie étroitement au métal de base, offrant une excellente résistance aux rayures et à la décoloration due à l'exposition aux UV.

- Coloration électrolytique : La feuille polie est immergée dans une solution électrolytique et un courant électrique est appliqué pour former un oxyde noir ou un film riche en chrome sur la surface. Cette méthode est rentable et produit une couleur uniforme.

- Sablage pour finition mate : Pour l'effet mat spécifié, la surface miroir colorée est soumise à un sablage. L'air à haute pression propulse de fines particules abrasives (par exemple, oxyde d'aluminium, carbure de silicium) sur la feuille, créant une texture subtile et non réfléchissante qui réduit l'éblouissement tout en préservant la teinte noire.

- Contrôle qualité et découpe : Les feuilles finies sont inspectées pour l'uniformité de la surface, l'uniformité de la couleur et la précision de l'épaisseur. Elles sont ensuite coupées aux tailles standard de 4 pieds * 8 pieds (ou aux dimensions personnalisées par commande) et emballées pour éviter les rayures pendant le transport.

3. Qualités et spécifications courantes

Qualités courantes d'acier inoxydable

| Qualité | Caractéristiques clés | Applications typiques |

|---|---|---|

| 304 | - Excellente résistance générale à la corrosion - Ductilité élevée (facile à plier/façonner) - Rentable pour une utilisation en intérieur et en extérieur modéré |

Décoration intérieure (panneaux muraux, comptoirs), meubles, panneaux d'appareils |

| 316L | - Résistance supérieure à la corrosion (résiste à l'eau salée, aux produits chimiques) - Faible teneur en carbone (empêche la corrosion intergranulaire) - Convient aux environnements difficiles |

Architecture extérieure (façades, garde-corps), équipements marins, dispositifs médicaux, zones de transformation des aliments |

| 201 | - Teneur en nickel plus faible (plus économique) - Bonne résistance à la corrosion dans les environnements intérieurs secs |

Projets intérieurs économiques (présentoirs, garnitures décoratives) |

Spécifications standard et personnalisées

- Épaisseur : Les 0,8 mm, 1,0 mm et 1,2 mm indiqués sont populaires pour les utilisations décoratives. Les autres épaisseurs courantes incluent 0,5 mm (ultra-mince, pour les conceptions légères) et 1,5 mm–3,0 mm (pour les applications intensives comme les panneaux de porte).

- Taille : 4 pieds * 8 pieds (1220 mm * 2440 mm) est la norme mondiale. Des tailles personnalisées (par exemple, 4 pieds * 10 pieds, 5 pieds * 10 pieds) ou des pièces coupées sur mesure sont disponibles pour des projets spécifiques.

- Finition : Comme spécifié, le produit offre une finition mate sablée ; d'autres options de finition sont détaillées dans la section 4.

4. Autres finitions de surface

- Finition miroir 8K : L'effet « miroir » classique avec une brillance ultra-élevée (8K), idéal pour créer un look luxueux et moderne dans les espaces haut de gamme (par exemple, les halls d'hôtel, les devantures de magasins).

- Finition brossée : Une texture linéaire, semblable à du satin, créée par un brossage mécanique. Il masque bien les empreintes digitales et est couramment utilisé pour les dosserets de cuisine, les portes d'ascenseur et les poignées de meubles.

- Finition Hairline : Une version plus fine de la finition brossée, avec des lignes extrêmement fines et subtiles. Il ajoute une touche délicate et sophistiquée aux éléments décoratifs comme les portes d'armoires ou les accents muraux.

- Finition gravée : Des motifs complexes (par exemple, des motifs géométriques, des logos) sont gravés sur la surface miroir noire à l'aide de techniques chimiques ou laser. Ceci est populaire pour la signalisation personnalisée, les installations artistiques ou la décoration intérieure de marque.

5. Applications

1. Décoration architecturale et intérieure

- Panneaux muraux, dalles de plafond et revêtements de colonnes dans les hôtels, les restaurants et les résidences de luxe (la finition mate réduit l'éblouissement dans les espaces bien éclairés).

- Cabines d'ascenseur, cadres de portes et garde-corps (la résistance à la corrosion assure une beauté à long terme dans les zones à fort trafic).

2. Meubles et appareils électroménagers

- Dessus de table, portes d'armoires et façades de tiroirs pour les cuisines et les salles de bains modernes (la qualité 304 résiste à l'humidité et aux taches).

- Panneaux pour réfrigérateurs, fours et appareils domestiques intelligents (la finition noire complète les conceptions d'appareils contemporains).

3. Commercial et détail

- Présentoirs, accessoires de magasin et signalisation dans les centres commerciaux, les boutiques et les magasins d'électronique (la surface élégante met en valeur les produits).

- Extérieurs de kiosques et comptoirs de réception (suffisamment durables pour résister à une utilisation quotidienne et faciles à nettoyer).

4. Extérieur et utilisations spécialisées

- Façades, auvents et garde-corps extérieurs dans les zones côtières ou urbaines (la qualité 316L résiste à la pluie, au sel et à la pollution atmosphérique).

- Boîtiers d'équipements médicaux et comptoirs de laboratoire (la surface non poreuse empêche la croissance bactérienne et est facile à désinfecter).

![]()

![]()

![]()

![]()