Tous les produits

-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

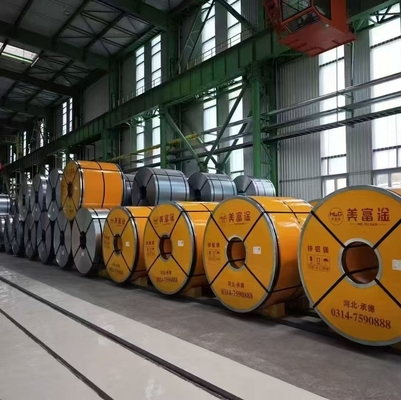

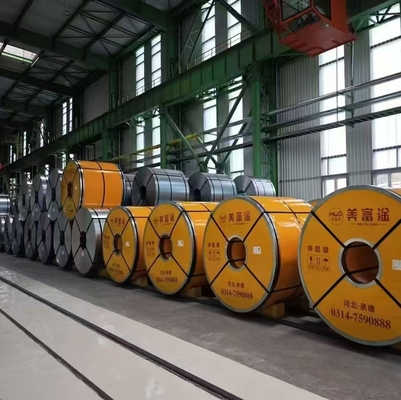

446 Stainless Steel Sheet 0.4-2.5mm 2B Finish Cold Rolled

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | BAOSTEEL TISCO |

| Certification | ISO |

| Numéro de modèle | 446 |

| Quantité de commande min | 1 tonne |

| Prix | 2000 - 3200 USD/Ton |

| Détails d'emballage | Emballage standard pour l'exportation |

| Délai de livraison | 5 - 12 jours en fonction de la quantité |

| Conditions de paiement | L / C, T / T, Western Union |

| Capacité d'approvisionnement | 20 tonnes par semaine |

Détails sur le produit

| Produits | feuille d'acier inoxydable | Grade | 446 |

|---|---|---|---|

| Épaisseur | 0,3 - 3,0 mm | Technologie | À froid roulé |

| Largeur | 1000mm 1219mm 1500mm ou coutumes comme demande | Surface | 2B HL de finissage de couleur du BA NO.1 NO.4 8K |

| Standard | EN DIN D'ASTM GIGAOCTET JIS | MOQ | 1 tonne |

| Mettre en évidence | Alloy 446 stainless steel sheet,UNS S44600 SS sheet 2B finishing,stainless steel sheet 0.4-2.5mm thickness |

||

Description de produit

Alloy 446 Stainless Steel Sheet UNS S44600 SS Sheet Thickness 0.4 - 2.5mm 2B Finishing

Stainless Steel 446 Plates Specifications:

| Specifications | ASTM A240, ASME SA240 |

| Standard | JIS, ASTM, AISI, GB, EN, DIN |

| Surface | 2B, 2D, BA, NO.4, NO.8, 8K, Mirror, Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching |

| Finish | Cold rolled, Hot rolled |

| Width | 1000-2000mm |

| Length | 1000-6000mm |

| Thickness | 0.40mm – 3.00mm |

1. Introduction

Alloy 446 stainless steel sheet, designated by the Unified Numbering System (UNS) as S44600, is a premium ferritic stainless steel product renowned for its exceptional resistance to high temperatures, corrosion, and oxidation. Unlike austenitic stainless steels (e.g., 304, 316), UNS S44600 is characterized by a high chromium content (25–27%) and low carbon content, which eliminates the risk of sensitization (carbide precipitation) during welding or heat treatment. This sheet product, with a thickness range of 0.4–2.5mm and 2B finishing, balances formability, durability, and cost-effectiveness, making it a preferred choice for industries requiring reliable performance in harsh environments—such as high-temperature processing, chemical exposure, or marine settings.

2. Chemical Composition (Key Parameters)

The chemical composition of UNS S44600 stainless steel is strictly controlled to ensure its superior properties. Below is the typical composition per industry standards:

| Element | Content Range (%) | Role |

|---|---|---|

| Chromium (Cr) | 25.0 – 27.0 | Enhances oxidation, corrosion, and high-temperature resistance |

| Iron (Fe) | Balance | Base metal providing structural strength |

| Carbon (C) | ≤ 0.10 | Minimizes sensitization and improves weldability |

| Manganese (Mn) | ≤ 1.50 | Improves hot workability without compromising corrosion resistance |

| Silicon (Si) | ≤ 1.00 | Aids in deoxidation during production and boosts high-temp strength |

| Phosphorus (P) | ≤ 0.040 | Controlled to avoid brittleness and maintain ductility |

| Sulfur (S) | ≤ 0.030 | Reduces machinability slightly but preserves corrosion performance |

| Nitrogen (N) | ≤ 0.040 | Enhances tensile strength without significant impact on formability |

3. Mechanical & Physical Properties

3.1 Mechanical Properties (for 2B Finished Sheets, Thickness 0.4–2.5mm)

| Property | Standard Value | Test Condition |

|---|---|---|

| Tensile Strength (σb) | ≥ 515 MPa (75 ksi) | Room temperature, annealed |

| Yield Strength (σ0.2) | ≥ 275 MPa (40 ksi) | Room temperature, annealed |

| Elongation (in 50mm) | ≥ 20% | Room temperature, annealed |

| Hardness (Brinell) | ≤ 183 HB | Annealed state |

| Hardness (Rockwell B) | ≤ 88 HRB | Annealed state |

3.2 Physical Properties

| Property | Value |

|---|---|

| Density | 7.7 g/cm³ (0.278 lb/in³) |

| Melting Point Range | 1427 – 1455 °C (2600 – 2650 °F) |

| Thermal Conductivity | 25 W/(m·K) at 20 °C (68 °F) |

| Coefficient of Thermal Expansion (20–100 °C) | 10.8 × 10⁻⁶/°C (6.0 × 10⁻⁶/°F) |

| Electrical Resistivity | 0.6 Ω·mm²/m at 20 °C (68 °F) |

4. Product Specifications

This UNS S44600 stainless steel sheet is manufactured to strict dimensional and finishing standards, with the following key specifications:

| Specification Item | Details |

|---|---|

| Thickness Range | 0.4 mm – 2.5 mm (tolerance: ±0.02 mm for thickness <1.0 mm; ±0.03 mm for thickness ≥1.0 mm) |

| Width | Customizable, common ranges: 1000 mm, 1219 mm, 1500 mm (max width: 2000 mm) |

| Length | Customizable, common ranges: 2000 mm, 2438 mm, 3000 mm (max length: 6000 mm) |

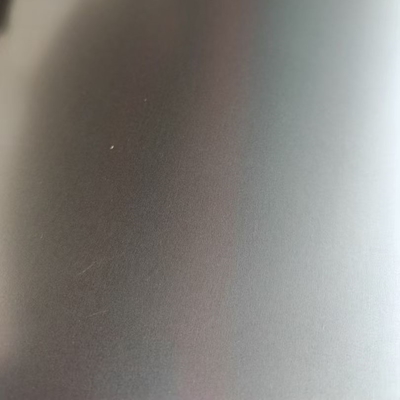

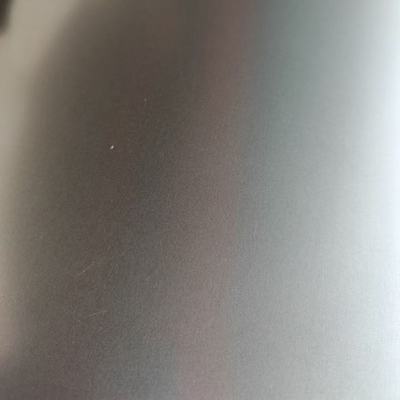

| Surface Finishing | 2B Finish: Cold-rolled, heat-treated, pickled, and skin-passed. Features a smooth, matte, and uniform surface—ideal for applications requiring moderate aesthetics and easy cleaning. |

| Flatness | ≤ 1 mm/m (meets ASTM flatness standards for thin-gauge stainless steel sheets) |

| Cutting Options | Standard: Slit coils or cut-to-size sheets; Custom: Laser cutting, plasma cutting, or shearing (per customer request) |

5. Manufacturing & Quality Standards

To ensure consistency and performance, the UNS S44600 stainless steel sheet complies with global industry standards:

| Standard Category | Relevant Standards |

|---|---|

| Chemical Composition | ASTM A240/A240M, ASME SA-240, EN 10088-2 |

| Mechanical Properties | ASTM A240/A240M, ISO 3506-1 |

| Dimensional Tolerances | ASTM A480/A480M (for thickness, width, and length), EN 10058 |

| Surface Finish (2B) | ASTM A480/A480M, EN 10088-2 (Designation: 1D + 2B) |

| Weldability | AWS D1.6 (stainless steel welding standard) |

| Quality Control | ISO 9001:2015 (quality management system), ISO 14001 (environmental management) |

6. Key Features

UNS S44600 stainless steel sheets (0.4–2.5mm, 2B finish) stand out for the following advantages:

- Exceptional High-Temperature Resistance: Sustains strength and oxidation resistance up to 815 °C (1500 °F), making it suitable for high-heat applications (e.g., furnace parts, heat exchangers).

- Superior Corrosion Resistance: High chromium content provides resistance to general corrosion, pitting, and crevice corrosion in mild acids, alkalis, and marine environments (outperforms 430 ferritic stainless steel).

- No Sensitization Risk: Low carbon content prevents carbide precipitation at grain boundaries during welding, eliminating intergranular corrosion.

- Good Formability: The 0.4–2.5mm thin gauge and 2B finish enable easy bending, rolling, and stamping—ideal for fabricating complex components.

- Cost-Effective: Lower nickel content (compared to austenitic grades like 316) reduces material costs while maintaining reliable performance.

- Smooth 2B Surface: The matte, uniform finish is non-reflective, easy to clean, and compatible with post-processing (e.g., painting, coating).

7. Applications

Thanks to its balanced properties, this UNS S44600 stainless steel sheet is widely used across industries:

- High-Temperature Processing: Furnace liners, heat exchanger tubes, boiler components, and kiln parts.

- Chemical & Petrochemical: Storage tanks for mild acids (e.g., sulfuric acid, nitric acid), chemical processing equipment, and pipe cladding.

- Marine & Coastal: Boat hulls, coastal architectural trim, and offshore platform components (resists saltwater corrosion).

- Automotive: Exhaust systems, catalytic converter housings, and underbody components (withstands high heat and road salt).

- Appliances: Oven interiors, grills, and heat-resistant panels for kitchen appliances.

- Construction: Decorative trim for industrial buildings, HVAC ductwork, and fire-rated components.

8. Packaging & Shipping

To protect the sheet’s 2B finish and prevent damage during transit, the following packaging measures are implemented:

- Individual Sheet Protection: Each sheet is wrapped in a PE (polyethylene) film to resist moisture, dust, and scratches.

- Stack Packaging: Sheets are stacked on a plywood pallet (or steel pallet for heavy loads) and secured with steel straps to prevent shifting.

- Moisture Barrier: For sea shipping or humid environments, the entire pallet is covered with a kraft paper + aluminum foil composite bag to block moisture and corrosion.

- Labeling: Each package is labeled with product details (UNS S44600, thickness, size, finish), batch number, and handling instructions (e.g., “Keep Dry,” “Handle with Care”).

- Shipping Options: Available via sea freight (for bulk orders), air freight (for urgent orders), or land transport (for regional deliveries). Custom packaging (e.g., wooden crates) is available upon request

![]()

![]()

![]()

![]()

produits recommandés