-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Hot Rolled & Forged Duplex 2205 Stainless Steel Round Bar Solid Solution Finishing SS Bar

| Place of Origin | China |

|---|---|

| Brand Name | Delta |

| Certification | ISO 9001 |

| Model Number | UNS S32205 / 2205 / 1.4462 |

| Minimum Order Quantity | 500 kgs |

| Price | 2000-3200 USD/Ton |

| Packaging Details | wooden box or water resistant paper surround |

| Delivery Time | 5 - 10 days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 50 Ton per Month |

| Products Name | Stainless Steel Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m Or Cutting Any Length As Request | Surface | Pickling Or Bright |

| Service | Cutting | Standard | ASTM DIN GB EN |

| Other Products | Round Bar, Square Bar, Flat Bar.etc | Technique | Hot Rolled |

| Highlight | Hot Rolled 2205 Duplex Stainless Steel Bar,Forged Duplex 2205 SS Round Bar,Solid Solution Finished Stainless Steel Bar |

||

Hot Rolled & Forged Duplex 2205 Stainless Steel Round Bar Solid Solution Finishing SS Bar

Products Specification

| Products Name | Stainless Steel Round Bar |

| Grade |

304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Products Diameter Range | φ10mm - φ350mm |

| Length | 6m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 500 kgs |

Hot Rolled & Forged Duplex 2205 Stainless Steel Round Bar Solid Solution Finishing SS Bar

Introduction to Duplex 2205 Stainless Steel Round Bar

Duplex 2205 stainless steel, also known as UNS S32205, is a high-strength, corrosion-resistant alloy composed of a balanced mix of austenitic and ferritic microstructures. This material is widely used in industries requiring exceptional strength, durability, and resistance to both stress corrosion cracking and general corrosion. Hot rolled and forged duplex 2205 stainless steel round bars are available with solid solution finishing, making them suitable for demanding applications in diverse environments.

Duplex 2205 is one of the most commonly used duplex stainless steels due to its superior properties compared to other alloys in terms of corrosion resistance, strength, and toughness. It is often utilized in the manufacturing of shafts, valves, pressure vessels, and heat exchangers.

Key Properties and Performance of Duplex 2205 Stainless Steel

Mechanical Properties:

-

Tensile Strength: Duplex 2205 stainless steel offers a tensile strength ranging between 620 and 880 MPa (90,000 to 130,000 psi).

-

Yield Strength: The yield strength is about 450 MPa (65,000 psi), which is approximately double that of 304 and 316 stainless steels.

-

Elongation: Typically, the elongation at break is 25% in 50 mm (2 inches), ensuring the material maintains good ductility and formability even under stress.

-

Hardness: Duplex 2205 generally has a Brinell hardness number (BHN) between 280 and 350, depending on the specific processing method and material condition.

Corrosion Resistance:

-

Duplex 2205 exhibits excellent resistance to a wide range of corrosion types, including pitting, crevice corrosion, and stress corrosion cracking, which makes it suitable for harsh environments.

-

It is particularly resistant to chloride-induced stress corrosion cracking, making it an ideal choice for use in marine environments or other chloride-rich environments.

-

Its resistance to intergranular corrosion and oxidation also contributes to its long-lasting performance in high-temperature and acidic environments.

Temperature Resistance:

-

Duplex 2205 maintains excellent properties at elevated temperatures. It can be used at temperatures up to 300°C (572°F), though higher temperatures can affect its corrosion resistance.

-

At temperatures above 300°C, it is recommended to use higher-alloy duplex or super duplex stainless steels for optimal performance.

Weldability and Formability:

-

Duplex 2205 stainless steel can be welded using most common welding techniques. However, due to its high chromium and molybdenum content, it is important to use a low heat input during welding to prevent the formation of sigma phase, which could degrade the material's properties.

-

Post-weld heat treatment is generally not required for most applications; however, welding should be performed using proper procedures to minimize the risk of embrittlement.

Industry Standards for Duplex 2205 Stainless Steel

Duplex 2205 stainless steel conforms to various international standards, ensuring its quality, consistency, and suitability for a broad range of applications. These standards include:

-

ASTM A276 – Standard Specification for Stainless Steel Bars and Shapes

-

ASTM A479 – Standard Specification for Stainless Steel Bars for Structural Use

-

ASTM A240 – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications

-

EN 10088-3 – Stainless Steels – Part 3: Technical Delivery Conditions for Semi-Finished Products, Bars, and Rods

-

UNS S32205 – Unified Numbering System designation for Duplex 2205 Stainless Steel

-

ASME SA-479 – Standard Specification for Stainless Steel Bars for Use in Boilers and Pressure Vessels

These standards ensure that the material complies with strict quality control and is suitable for use in applications where strength, corrosion resistance, and reliability are paramount.

Common Equivalent Grades

Duplex 2205 is recognized by several international standards, and it has several equivalent grades. These equivalents may differ slightly in chemical composition or mechanical properties but offer similar overall performance. Common equivalents of Duplex 2205 include:

-

EN 1.4462: The European equivalent of Duplex 2205 stainless steel, often referred to as "European Duplex 2205."

-

SS 32205: A designation used in various regions, including the US.

-

F51: A designation used in the ASTM standard.

-

DSS 2205: Another common shorthand name used for Duplex 2205 stainless steel in certain markets.

Applications of Duplex 2205 Stainless Steel Round Bars

Due to its unique combination of strength and corrosion resistance, Duplex 2205 stainless steel is employed in various industries, including:

-

Chemical Processing:

-

Pipes and Tanks: Duplex 2205 is commonly used for pipes, tanks, and other equipment exposed to aggressive chemicals like hydrochloric acid, sulfuric acid, and phosphoric acid.

-

Heat Exchangers: The material’s ability to resist chloride stress corrosion cracking makes it an excellent choice for heat exchangers in chemical plants.

-

-

Marine Applications:

-

Offshore Platforms: Duplex 2205’s superior resistance to seawater and its stress corrosion cracking resistance make it an ideal material for offshore structures, including pipelines, risers, and seawater desalination plants.

-

Shipbuilding: Components exposed to seawater such as shafts, propellers, and hull structures benefit from the high corrosion resistance of Duplex 2205.

-

-

Oil and Gas Industry:

-

Downhole Equipment: In downhole oil and gas applications, Duplex 2205 is used for equipment like tubing, pumps, and casings, where both strength and resistance to corrosive environments are critical.

-

Pressure Vessels and Heat Exchangers: Used in high-pressure systems where resistance to sulfur and chloride environments is required.

-

-

Water Treatment:

-

Desalination Plants: Its resistance to chloride ions and corrosion in high-salinity water makes Duplex 2205 ideal for desalination plants.

-

Piping Systems: Duplex 2205 is used in water treatment plants for pipelines, valves, and fittings due to its resistance to corrosion in water-rich environments.

-

-

Aerospace & Automotive:

-

Duplex 2205 is used in high-stress automotive and aerospace applications, such as turbine blades and structural components, where both high strength and resistance to heat and corrosion are necessary.

-

Other Products Available in Duplex 2205

In addition to round bars, Duplex 2205 stainless steel is also available in a variety of other shapes and forms, including:

-

Duplex 2205 Stainless Steel Plate and Sheet: Available in various thicknesses, commonly used for structural components, chemical process tanks, and heat exchangers.

-

Duplex 2205 Stainless Steel Pipe and Tube: Ideal for fluid transport in industries like oil and gas, chemical processing, and marine applications.

-

Duplex 2205 Stainless Steel Fittings and Flanges: Used in pipeline systems where corrosion resistance and high strength are required.

-

Duplex 2205 Stainless Steel Welded Tubing: Available for applications where ease of installation is critical.

Advantages of Choosing Duplex 2205 Stainless Steel

-

High Strength: The alloy’s high yield strength allows for the design of thinner-walled structures that can still carry heavy loads, reducing the weight of the overall structure.

-

Superior Corrosion Resistance: Duplex 2205's ability to resist chloride-induced stress corrosion cracking and general corrosion makes it suitable for challenging environments, such as marine or chemical plant applications.

-

Cost-Effective Solution: While Duplex 2205 stainless steel is more expensive than conventional austenitic stainless steels, its excellent performance in demanding environments often leads to lower overall maintenance costs and longer service life.

-

Improved Safety: The alloy’s ability to withstand corrosive and high-stress conditions without failure improves the overall safety and reliability of the systems in which it is used.

Conclusion

Duplex 2205 stainless steel round bars, available in both hot-rolled and forged forms with solid solution finishing, are highly versatile materials known for their strength, corrosion resistance, and durability. These properties make them an essential material for applications in industries such as chemical processing, oil and gas, marine, and water treatment. By meeting rigorous international standards and offering excellent resistance to stress corrosion cracking, Duplex 2205 is an optimal choice for demanding applications where both strength and longevity are crucial.

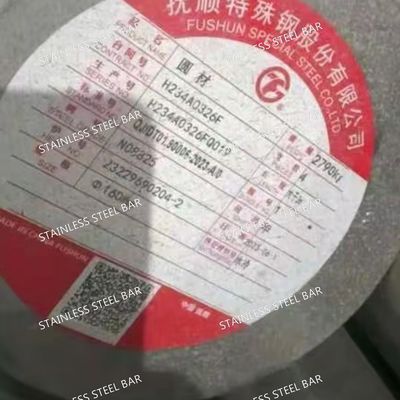

![]()

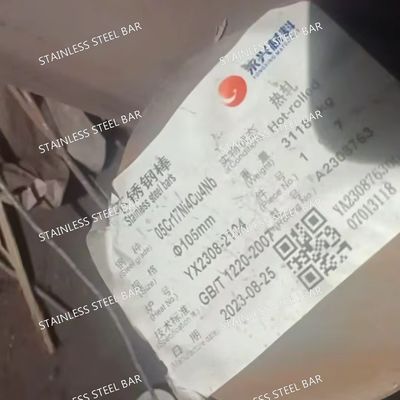

![]()

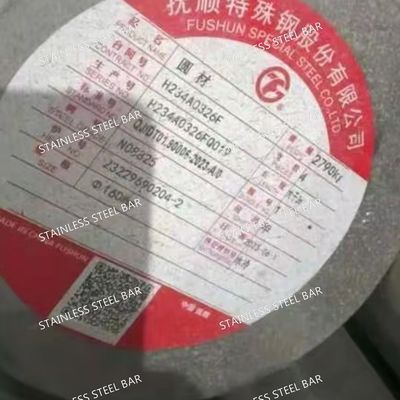

![]()

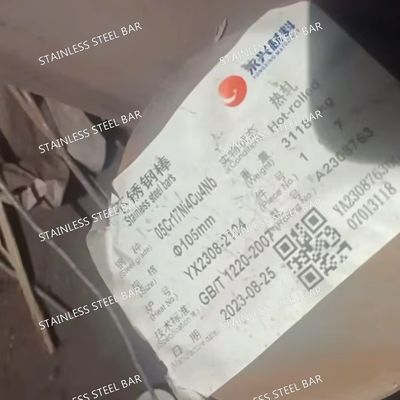

![]()