-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

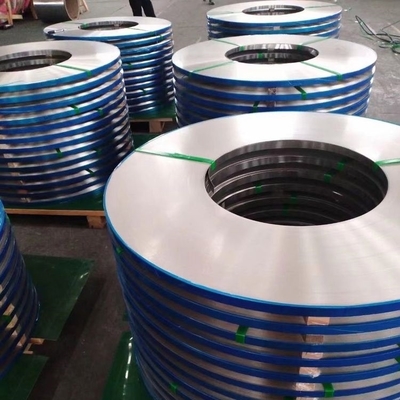

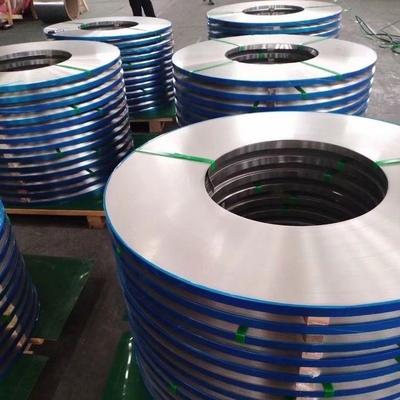

Corrosion-Resistant C276 Alloy Strip for Aerospace & Chemical Processing

| Products | Hastelloy C276 Strips | Grade | UNS N10276 |

|---|---|---|---|

| Thickness | 0.1 - 2.5mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Custom Cutting Strips In Any Width And Thickness |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | C276 alloy corrosion-resistant strip,nickel alloy aerospace strip,chemical processing C276 alloy strip |

||

Corrosion-Resistant C276 Alloy Strip for Aerospace & Chemical Processing

Quick Informations

| Grade | Hastelloy C276 / 2.4819 | Type | strips |

| Thickness | 0.1 - 2.5mm | Width | 5 - 1219mm as request |

| Surface | 2B | Innder Diameter | 508mm or as request |

More Specification Informations

| Products Name | Hastelloy C276 Nickel Alloy strips |

| Thickness | 0.1 - 2.5mm |

| Width | 5 - 1219mm |

| Surface | 2B |

| Brand | DELTA |

| Service | Small coil processing |

| MOQ | 2 Kgs |

| Other Type | round bar, sheet,plate,coil,pipe.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Corrosion-Resistant C276 Alloy Strip for Aerospace & Chemical Processing

Introduction

Hastelloy C276, a nickel-chromium-molybdenum tungsten alloy, is universally recognized as a premier solution for combating severe corrosion in demanding environments. Its exceptional resistance to a wide spectrum of corrosive media makes it an indispensable material for critical applications in the aerospace and chemical processing industries (CPI). This product information sheet details the properties, specifications, and applications of our precision-manufactured C276 alloy strip, engineered to meet the most stringent quality and performance standards.

Key Characteristics and Advantages

The outstanding performance of Hastelloy C276 stems from its carefully balanced chemical composition, which provides a unique combination of properties:

-

Exceptional Corrosion Resistance: This is its defining feature. C276 exhibits excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. It handles oxidizing and reducing agents with ease, making it highly effective in environments containing chlorides, sulfuric acid, hydrochloric acid, phosphoric acid, and other aggressive chemicals.

-

Versatility: Its wide-ranging corrosion resistance eliminates the need for multiple specialized alloys, simplifying inventory and design choices for equipment that faces varied chemical exposures.

-

High Strength: It maintains excellent mechanical properties at both elevated temperatures (up to approximately 1000°C / 1832°F) and cryogenic temperatures, ensuring structural integrity under extreme conditions.

-

Fabrication Friendly: Despite its high strength, C276 strip can be readily fabricated and formed using standard techniques, allowing for the production of complex components like springs, seals, and diaphragms.

Chemical Composition (Typical % Weight)

| Element | Content (%) | Element | Content (%) |

|---|---|---|---|

| Nickel (Ni) | Balance | Iron (Fe) | 4.0 - 7.0 |

| Chromium (Cr) | 14.5 - 16.5 | Tungsten (W) | 3.0 - 4.5 |

| Molybdenum (Mo) | 15.0 - 17.0 | Carbon (C) | ≤ 0.01 |

| Cobalt (Co) | ≤ 2.5 | Manganese (Mn) | ≤ 1.0 |

| Vanadium (V) | ≤ 0.35 | Silicon (Si) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.025 | Sulfur (S) | ≤ 0.02 |

Note: Low carbon and silicon content is crucial for minimizing carbide precipitation during welding, which preserves corrosion resistance in the heat-affected zone (HAZ).

Physical & Mechanical Properties (Room Temperature)

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.89 g/cm³ | 0.321 lb/in³ |

| Melting Point | 1323 - 1371 °C | 2413 - 2500 °F |

| Tensile Strength | ≥ 690 MPa | ≥ 100 ksi |

| Yield Strength (0.2% Offset) | ≥ 283 MPa | ≥ 41 ksi |

| Elongation | ≥ 40% | ≥ 40% |

Available Specifications and Standards

Our precision C276 strip is manufactured under strict quality control to comply with various international standards, ensuring consistency and reliability for critical components.

Common Standards:

-

ASTM B575: Standard Specification for Low-Carbon Nickel-Molybdenum-Chromium, Nickel-Chromium-Molybdenum, and Nickel-Chromium-Molybdenum-Tungsten Alloy Plate, Sheet, and Strip.

-

AMS 5754: Aerospace Material Specification governing the chemical and mechanical properties of strip used in flight-critical applications.

-

ASME SB-575: Equivalent to ASTM B575 for pressure vessel and boiler code applications.

-

NACE MR0175/ISO 15156: Approved for use in sour service (oil & gas) environments containing H₂S.

Available Forms & Dimensions:

Our precision strip is available in cold-rolled annealed and pickled finish.

-

Thickness: 0.05 mm to 2.0 mm (0.002" to 0.078")

-

Width: 2.0 mm to 500 mm (0.08" to 20")

-

Temper: Annealed (soft) to various spring tempers, tailored to application requirements.

Applications in Aerospace & Chemical Processing

The unique properties of C276 strip make it the material of choice for numerous high-stakes applications.

Aerospace:

-

Engine Components: Used for seals, shrouds, and containment rings where exposure to high temperatures and corrosive combustion by-products is a concern.

-

Fasteners and Springs: Critical for its high strength-to-weight ratio and resistance to atmospheric and chemical corrosion.

-

Exhaust Systems: Components in auxiliary power units (APUs) and other systems requiring heat and corrosion resistance.

Chemical Processing & Petrochemical:

-

Pollution Control: Fabricated into strip for flue gas desulfurization (FGD) systems, handling wet chlorine gas and chlorinated salts.

-

Reactor Components: Used for catalyst grids, liners, and baffles in reactors processing aggressive acids.

-

Gaskets & Seals: Precision-formed into C-rings and other seals for pumps, valves, and vessels handling corrosive media.

-

Heat Exchangers: Strip can be fabricated into parts for heat exchangers in acid service.

Why Choose Our C276 Alloy Strip?

We provide more than just a metal strip; we deliver a guaranteed performance solution. Our product undergoes rigorous in-process testing, including dimensional checks, mechanical property validation, and surface quality inspection. Advanced slitting and edging techniques ensure a flawless, burr-free product that is ready for your precision fabrication processes, minimizing waste and maximizing yield.

![]()

![]()

![]()

![]()