All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

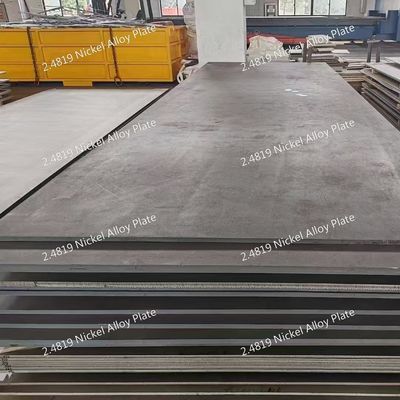

DIN 2.4819 Nickel Alloy Plate (Hastelloy C-276)

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Nickel Alloy Plate | Grade | 2.4819 |

|---|---|---|---|

| Thickness | 1.0 - 30.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

Product Description

DIN 2.4819 Nickel Alloy Plate (Hastelloy C-276)

Quick Informations

| Grade | Hastelloy C276 / 2.4819 | Type | Sheet, Plate |

| Thickness | 1.0-25.0mm | Width | 1219mm,1500mm |

| Length | Within 6m | Service | Laser Cutting |

More Specification Informations

| Products Name | DIN 2.4819 Nickel Alloy Sheet , Plate |

| Thickness | cold rolled 1.0 - 3.0mm, hot rolled 4.0 - 25.0mm |

| Standard Size | 1000*2000mm,1219*2438mm,1500*6000mm |

| Surface | 2B, NO.1 |

| Brand | DELTA |

| Service | Laser cutting |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Chemical Composition

Mechanical Properties

Corrosion Resistance

High-Temperature Performance

Fabrication and Processing

Standards and Equivalents

Typical Applications

Surface and Heat Treatment

![]()

![]()

![]()

![]()

Recommended Products