-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

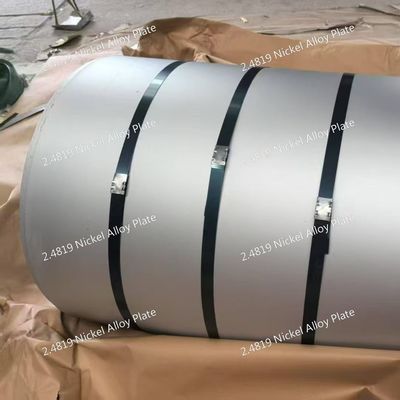

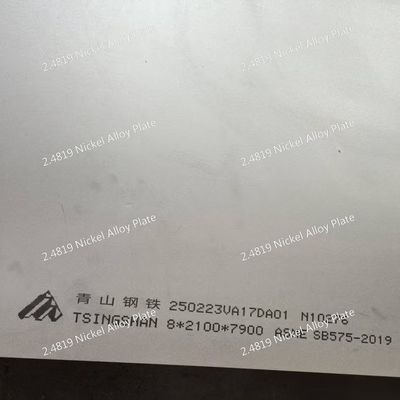

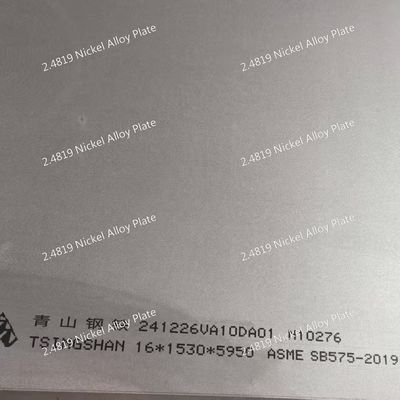

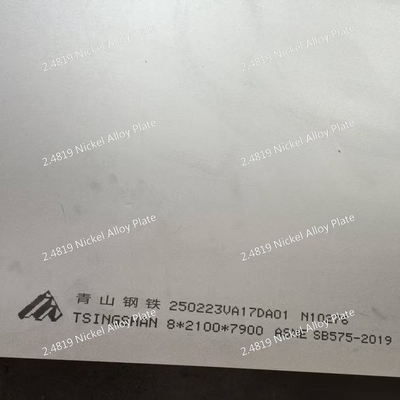

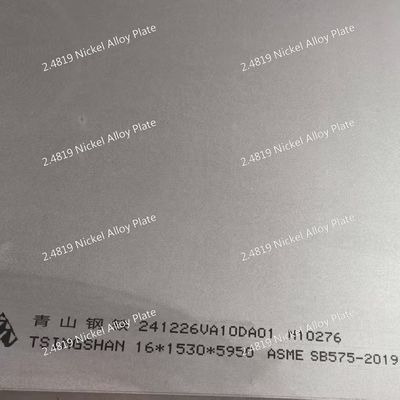

DIN 2.4819 Nickel Alloy Plate Sheet Hastelloy C-276 High-Temperature Corrosion Resistant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Nickel Alloy Plate | Grade | 2.4819 |

|---|---|---|---|

| Thickness | 1.0 - 30.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

DIN 2.4819 Nickel Alloy Plate Sheet Hastelloy C-276 High-Temperature Corrosion Resistant

Quick Informations

| Grade | Hastelloy C276 / 2.4819 | Type | Sheet, Plate |

| Thickness | 1.0-25.0mm | Width | 1219mm,1500mm |

| Length | Within 6m | Service | Laser Cutting |

More Specification Informations

| Products Name | DIN 2.4819 Nickel Alloy Sheet , Plate |

| Thickness | cold rolled 1.0 - 3.0mm, hot rolled 4.0 - 25.0mm |

| Standard Size | 1000*2000mm,1219*2438mm,1500*6000mm |

| Surface | 2B, NO.1 |

| Brand | DELTA |

| Service | Laser cutting |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Comprehensive Technical Datasheet: DIN 2.4819 / C276 Nickel Alloy (Hastelloy C-276)

1. Alloy Overview of 2.4819 Alloy Plate

DIN 2.4819 (commonly known as Hastelloy® C-276, UNS N10276, W.Nr. 2.4819) is a nickel-molybdenum-chromium superalloy fortified with tungsten. It belongs to the Hastelloy C-family and is renowned for exceptional corrosion resistance in both oxidizing and reducing environments, spanning temperatures from cryogenic to 550°C356. Its low carbon content (≤0.01–0.08 wt.%) minimizes carbide precipitation during welding, making it ideal for as-welded applications610.

Equivalent Standards:

-

ASTM: UNS N10276

-

EN: NiMo16Cr15W

-

JIS: NW 0276

-

GB: NS330468

2 Chemical Composition of 2.4819

| Element | Composition (wt.%) | Role |

|---|---|---|

| Ni | Balance (~52–60%) | Matrix stability, ductility |

| Mo | 15.0–17.0 | Resistance to reducing acids (HCl, H₂SO₄) |

| Cr | 14.5–16.5 | Oxidation resistance |

| W | 3.0–4.5 | Enhances pitting/cl crevice corrosion resistance |

| Fe | 4.0–7.0 | Cost optimization |

| C | ≤0.01–0.08 | Ultra-low to prevent intergranular corrosion |

| Trace elements (Mn ≤1.0%, Si ≤0.08%, P ≤0.04%, S ≤0.03%) tightly controlled358. |

Mechanical & Physical Properties

-

Tensile Strength: ≥690 MPa

-

Yield Strength (0.2% offset): ≥283 MPa

-

Elongation: ≥40%

-

Density: 8.89–8.90 g/cm³

-

Melting Point: 1325–1370°C

-

Hardness: ≤230 HB378

Corrosion Resistance of 2.4819 Alloy

-

Acid Resistance: Superior performance in sulfuric, hydrochloric, phosphoric, acetic, and formic acids at concentrations ≤65% and temperatures up to boiling point510.

-

Chloride Immunity: Resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in seawater, brine, and chlorinated solvents26.

-

Unique Capabilities: One of few alloys suitable for wet chlorine, hydrofluoric acid (HF), and flue gas desulfurization (FGD) systems47.

3. Common Product Forms & Specifications

DIN 2.4819 / C276 is available in multiple industrial forms, compliant with international standards:

3.1 Bar/Rod (ASTM B574)

-

Diameter: 3–250 mm (customizable up to 350 mm for forged bars)19.

-

Surface Finish: Bright annealed (smooth), black (as-forged).

-

Processing: Cold-drawn (precision dimensions), hot-rolled (heavy sections)12.

-

Mechanical Properties: As above, with elongation ≥40%18.

3.2 Plate/Sheet (ASTM B575)

-

Thickness: 0.025 mm (foil) – 150 mm (heavy plate); standard heavy plates up to 76.2 mm (3 inches)10.

-

Width/Length: Customizable via water-jet/laser profiling1.

3.3 Tubular Products

-

Seamless Tubes (ASTM B622): For high-pressure applications (e.g., heat exchangers).

-

Welded Pipes (ASTM B619/B626): Nominal and structural piping for chemical processing810.

3.4 Forgings & Fittings (ASTM B564)

-

Forms: Flanges, valves, pump components.

-

Certification: Compliant with ASME B16.5/B16.9 for pressure systems810.

3.5 Welding Consumables

-

Filler Metal: ERNiCrMo-4 (AWS A5.14).

-

Process Compatibility: TIG (GTAW), MIG (GMAW), SMAW. No post-weld heat treatment required610.

4. Target Applications

| Industry | Critical Components |

|---|---|

| Chemical Processing | Reactors, evaporators, acid storage tanks |

| Pollution Control | FGD scrubbers, stack liners, dampers |

| Marine/Offshore | Seawater pipelines, heat exchangers |

| Pulp & Paper | Digesters, bleach washers |

| Pharmaceuticals | Reactors for acetic/formic acid synthesis |

| Also used in nuclear cooling systems and waste treatment plants467. |

5. Supply & Customization Capabilities

-

Certifications: NACE MR0175 (sour gas service), EN 10204 3.1, ISO610.

-

Packaging: Standard export crates (e.g., 120×90×12 cm for plates), corrosion-inhibitive wrapping19.

-

Lead Time: 10 days for small orders (≤500 kg), 40 days for bulk (≥5,000 kg)1.

-

Customization: LOGO/pattern engraving, size tailoring (min. order: 500 kg for plates, 1,000 kg for branding)19.

6. Why Choose DIN 2.4819 / C276?

-

Versatility: Performs in mixed acid environments (e.g., HNO₃ + HCl) where stainless steels (e.g., 316L) fail710.

-

Cost Efficiency: 10× longer service life in FGD systems compared to alternatives, reducing downtime costs6.

-

Global Stock: Major suppliers in Wuxi, Jiangsu; ISO-certified mills ensure consistent quality

![]()

![]()

![]()

![]()