-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

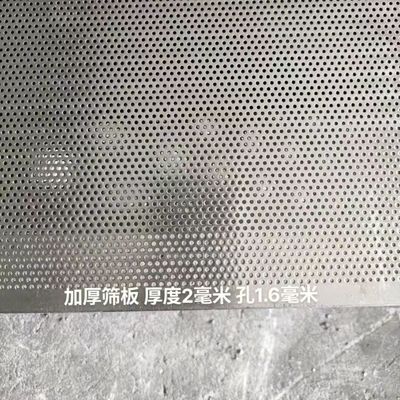

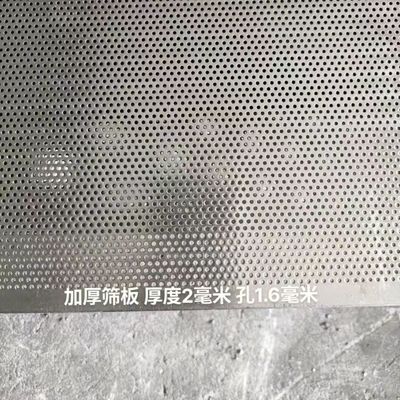

Economical 304 Stainless Steel Perforated Screen – Cost-Effective, High Permeability & Reliable for Agricultural Filtration, Drainage & Sound Insulation

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 304 316L 430 410S.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2100 - 3200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Micro Perforated Sheet | Grade | 304 201 316L 430 410S.etc |

|---|---|---|---|

| Hole Diameter | 0.1 - 10.0mm | Size | 1000*2000mm 1219*2438mm 1500*3000mm |

| Thickness | 0.3 - 3.0mm | Type | Cold Rolled |

| Surface | 2B | Application | Industrial |

| Packing | Wooden Pallets |

Economical 304 Stainless Steel Perforated Screen – Cost-Effective, High Permeability & Reliable for Agricultural Filtration, Drainage & Sound Insulation

Products Specification:

| Product Name | Stainless Steel Perforated Sheet |

| Grade | 201 304L 304 309S 310S 321 317L 316L 316Ti 2205 2507 904L 254SMO 409L 436 441.etc |

| Hole Shape | Diamond, Round, Square, Hexagon |

| Size for mesh panel | 1000*2000mm, 1200*2400mm, 1250mm*2500mm, as customized |

| Hang Thickness | 0.3mm-10mm |

| Hole Size | Diameter 0.1 - 10.0mm |

| Techniqe | Perforated |

| Application | Office Ceiling, Building protection, Indoor decoration |

Product Information: 304 Stainless Steel Perforated Sheet

1. Product Introduction

304 Stainless Steel Perforated Sheet is a high-performance industrial and architectural material created by precision-punching arrays of holes into sheets of AISI 304 austenitic stainless steel. Renowned for its exceptional corrosion resistance, durability, and hygienic properties, it offers an optimal blend of functionality, strength, and aesthetic appeal. This versatile product serves critical roles in filtration, screening, ventilation, safety, and design across diverse industries.

2. Key Product Parameters & Specifications

| Parameter | Specification / Range |

|---|---|

| Material | AISI 304 (UNS S30400, EN 1.4301) |

| Composition | ~18% Chromium, ~8% Nickel, Low Carbon (<0.08%) |

| Thickness (Gauge) | 0.5mm (22 Ga) to 6.0mm (1/4") [Standard Range; Custom Available] |

| Sheet Size | Standard: 1000x2000mm, 1220x2440mm (4'x8'), 1500x3000mm. Custom Sizes Available. |

| Hole Shapes | Round, Square, Slotted (Rectangular), Hexagonal, Custom Patterns. |

| Hole Diameter (Round) | 0.8mm (0.031") to 30mm (1.18")+ |

| Slot Width (Slotted) | 1mm (0.04") to 20mm (0.79")+ |

| Stagger (Pitch) | Variable (Center-to-Center Distance), Determined by hole size & open area requirement. |

| Open Area % | 3% to 80% (Dependent on Hole Size, Pattern, and Pitch) |

| Surface Finish | Standard Mill Finish (2B). Options: Brushed (No.4), Satin, Mirror Polished (No.8). |

| Tolerance | Manufactured per ASTM E2016, DIN 24041, or customer specification. |

3. Material Standards & Compliance

-

Base Material: Conforms to ASTM A240/A240M (Pressure Vessels), ASTM A666 (Annealed or Cold-Worked), ASME SA-240, EN 10088-2, JIS G4305.

-

Perforation Standards: Typically follows ASTM E2016 (Specification for Perforated Plate) or DIN 24041 (Perforated Sheet Metal).

-

Corrosion Resistance: Excellent resistance to atmospheric corrosion, most organic chemicals, food processing environments, sterilizing solutions, and many inorganic chemicals. Meets requirements for food contact (subject to specific regulations).

-

Certifications: Material Test Certificates (MTC/MTR) available. RoHS compliant.

4. Manufacturing & Processing Methods

-

Primary Method: Precision CNC Turret Punching: High-speed, computer-controlled punching machines using hardened tooling dies create consistent, accurate holes with minimal burring. Ideal for high volumes and complex patterns.

-

Secondary Methods (Less Common for 304):

-

Laser Cutting: Used for very thick plates (>6mm), intricate custom patterns, or low-volume prototypes where punching tooling is impractical. Higher cost, potential for heat-affected zone (HAZ).

-

Photochemical Etching: Used for extremely fine holes (<0.8mm) or very thin sheets where punching might distort the material. Lower volume, higher cost.

-

-

Post-Processing:

-

Deburring: Edges are typically smooth as punched (minimal burr). Additional vibratory tumbling, brushing, or electropolishing available for ultra-smooth edges.

-

Leveling/Camber Correction: Ensures sheet flatness after punching.

-

Cutting to Size: Shearing, laser cutting, or waterjet cutting.

-

Forming: Easily bent, rolled, or formed into various shapes (guards, screens, chutes).

-

Welding: Excellent weldability using common methods (TIG, MIG, Spot Welding).

-

Surface Finishing: Polishing, brushing, passivation (to enhance corrosion resistance).

-

5. Key Advantages & Benefits

-

Superior Corrosion Resistance: Outstanding resistance to rust, oxidation, and a wide range of corrosive environments (atmosphere, moisture, mild acids/alkalis, food products). Ideal for harsh, humid, or washdown conditions.

-

High Strength & Durability: Maintains structural integrity under load, vibration, and elevated temperatures (up to ~870°C / 1600°F intermittent). Excellent impact resistance.

-

Hygienic & Easy to Clean: Non-porous, non-toxic surface prevents bacterial growth and allows easy cleaning with steam, detergents, or pressure washing. Essential for food, pharma, and medical uses.

-

Attractive Appearance: Bright, clean, modern aesthetic suitable for visible architectural and decorative applications. Polishing enhances reflectivity.

-

Excellent Fabricability: Easily punched, cut, formed, welded, and installed. Adapts readily to custom designs.

-

Long Service Life & Low Maintenance: Resists degradation, minimizing downtime, replacement costs, and maintenance needs.

-

Versatility: Wide range of hole patterns, sizes, and open areas enables countless functional and design solutions.

-

Fire Resistance: Non-combustible material.

-

Recyclability: 100% recyclable, environmentally responsible choice.

6. Primary Applications

-

Filtration & Separation: Sieves, screens, strainers, filter baskets, centrifuge liners, oil/gas demister pads, catalyst supports.

-

Architectural & Building: Facade cladding, sunscreens & brise-soleil, ceiling panels, balustrades & railings, signage, partitions, decorative screens, ventilation grilles.

-

Industrial & Machinery: Machine guards, safety walkways & platforms, conveyor belts/screens, silo screens, hopper liners, crusher screens, acoustic panels.

-

Food & Beverage Processing: Sorting screens, drying racks, fryer baskets, conveyor systems, juice presses, ingredient handling screens.

-

Chemical & Petrochemical: Process screens, scrubber internals, mist eliminators, reactor screens.

-

Agriculture & Mining: Grain sorting/drying screens, fertilizer screens, mineral sizing screens, crusher liners.

-

Automotive: Grilles, speaker covers, ventilation ducts, under-hood components.

-

Consumer Goods & Furniture: Speaker grilles, appliance panels, shelving, decorative elements.

Customization: Virtually all parameters (hole size, pattern, pitch, sheet size, thickness, finish) can be customized to meet specific project requirements.

Quality Assurance: Rigorous in-process and final inspection ensures dimensional accuracy, pattern consistency, hole quality, and material integrity.

![]()

![]()

![]()

![]()