-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

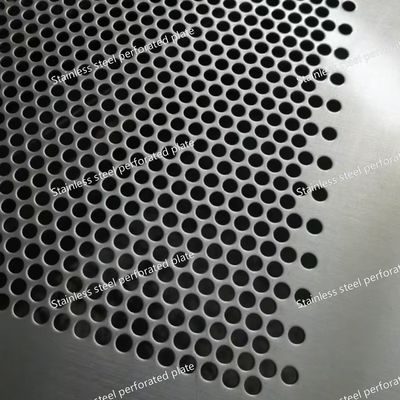

Precision Stainless Steel Micro Perforated Sheet Fine Hole Mesh for Filtration, Screening & Decoration

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 304 316L 430 410S.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 2100 - 3200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Micro Perforated Sheet | Grade | 304 201 316L 430 410S.etc |

|---|---|---|---|

| Hole Diameter | 0.1 - 10.0mm | Size | 1000*2000mm 1219*2438mm 1500*3000mm |

| Thickness | 0.3 - 3.0mm | Type | Cold Rolled |

| Surface | 2B | Application | Industrial |

| Packing | Wooden Pallets |

Precision Stainless Steel Micro Perforated Sheet Fine Hole Mesh for Filtration, Screening & Decoration

Products Specification:

| Product Name | Stainless Steel Perforated Sheet |

| Grade | 201 304L 304 309S 310S 321 317L 316L 316Ti 2205 2507 904L 254SMO 409L 436 441.etc |

| Hole Shape | Diamond, Round, Square, Hexagon |

| Size for mesh panel | 1000*2000mm, 1200*2400mm, 1250mm*2500mm, as customized |

| Hang Thickness | 0.3mm-10mm |

| Hole Size | Diameter 0.1 - 10.0mm |

| Techniqe | Perforated |

| Application | Office Ceiling, Building protection, Indoor decoration |

Overview

Our precision-engineered Stainless Steel Micro-Perforated Sheets offer exceptional durability, fine filtration, and versatile functionality. Manufactured using advanced laser or photo-etching technology, these sheets feature consistently sized micro-perforations for superior performance in demanding industrial applications.

Key Features & Benefits

-

High-Quality Material: Constructed from 304, 316, or 316L stainless steel, providing excellent corrosion resistance, strength, and thermal stability.

-

Precision Micro-Perforations: Available in hole diameters ranging from 0.05mm (50µm) to 3.0mm, with tight tolerances (±0.02mm typical).

-

Varied Hole Patterns: Choose from square, round, rectangular, hexagonal, or custom-designed hole configurations.

-

Optimal Open Area: Open Area Ratios from 1% to 70%+, customizable to balance flow-through, filtration efficiency, and structural integrity.

-

Smooth & Burr-Free Edges: Advanced manufacturing ensures clean holes with minimal material deformation for consistent performance.

-

Exceptional Durability: Resists wear, high temperatures (up to 800°C / 1472°F depending on grade), chemicals, and harsh environments.

-

Easy to Clean & Maintain: Non-porous surface prevents clogging and allows for easy sterilization (autoclavable) or cleaning.

-

Customizable: Tailored to your exact specifications – size, thickness (0.05mm to 3.0mm), hole size, pattern, pitch (spacing), and open area.

Technical Specifications

-

Material Grades: AISI 304, 304L, 316, 316L (Other grades like 430, 310, 321 available upon request)

-

Standard Sheet Sizes: 1000mm x 2000mm, 1220mm x 2440mm (48" x 96") (Custom sizes available)

-

Thickness Range: 0.05mm (0.002") to 3.0mm (0.118")

-

Hole Diameter (Typical Range): 0.05mm (0.002") to 3.0mm (0.118")

-

Hole Pitch (Center-to-Center): Customizable based on hole size and required open area.

-

Tolerance: Hole Size ±0.02mm (±0.0008"), Positional Accuracy ±0.05mm (±0.002")

-

Surface Finish: Standard Mill Finish, Electro-Polished, Satin Finish (Optional)

Applications

-

Precision Filtration & Sieving (Food/Bev, Pharma, Chemicals)

-

Fluidization & Aeration (Pneumatic Conveying, Process Beds)

-

Acoustic Dampening & Sound Absorption Panels

-

EMI/RFI Shielding

-

Ventilation & Airflow Control

-

Sensor Protection Screens

-

Decorative Panels & Architectural Facades

-

Battery Electrodes & Fuel Cell Components

-

Laboratory & Scientific Equipment

-

Spark Arrestors

Why Choose Our Micro-Perforated Sheets?

-

Consistent Quality: Rigorous quality control ensures uniformity and reliability.

-

Technical Expertise: Engineering support for optimal design based on your application needs.

-

Fast Prototyping & Lead Times: Efficient production capabilities.

-

Competitive Pricing: Value-driven manufacturing solutions.

-

Global Standards Compliance: Meets relevant industry specifications (ASTM, DIN, ISO, etc.).

Samples and Custom Quotes Available! Contact us to discuss your specific micro-perforation requirements.

Key elements used and why

-

Clear Title: Identifies the product immediately.

-

Concise Overview: Summarizes the product and key manufacturing methods.

-

Bulleted Features/Benefits: Highlights selling points and value proposition for the buyer (durability, precision, customizability, ease of use). Focuses on what it does for the customer.

-

Detailed Technical Specifications: Provides essential hard data engineers and buyers need (materials, sizes, tolerances, capabilities). Uses standard units (mm & inch).

-

Application List: Shows versatility and helps customers identify if it suits their use case. Includes major industrial sectors.

-

"Why Choose Us" Section: Builds trust and differentiates from competitors.

-

Strong Call to Action: Encourages the next step (requesting samples or a quote).

-

Professional Language: Formal, technical, yet clear and concise. Avoids excessive jargon but uses correct industry terms (perforation, pitch, open area, AISI grades, etc.).

-

Keywords: Includes terms buyers might search for (stainless steel, micro-perforated, sheet, screen, filter, holes, precision, perforated metal, laser cut, etched, 304, 316, open area, tolerance).

![]()

![]()

![]()