-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

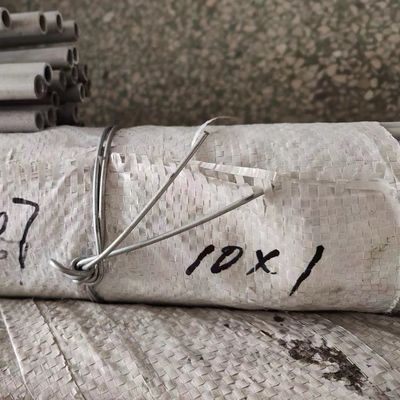

904L Stainless Steel Seamless Pipe | ASTM B673 UNS N08904 Welded & ERW With EN 10204-3.1 Certificate

| Products | Stainless Steel Pipe | Grade | 904L |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Industrial | Packing | Wooden Box Or PP Bag |

| Highlight | ASTM B673 Stainless Steel Seamless Pipe,ERW Stainless Steel Seamless Pipe,904L Stainless Steel Seamless Pipe |

||

904L Stainless Steel Seamless Pipe | ASTM B673 UNS N08904 Welded & ERW With EN 10204-3.1 Certificate

| Technical Data Sheet of Stainless Steel Pipe & Tube | |

| Product Name |

AISI 904L (UNS N08904, DIN 1.4539) Stainless Steel Seamless Pipes & Tubes |

| Equivalent Materials | AISI 904L, UNS N08904, DIN 1.4539, AISI 904L, SUS 890L, NAS 255, 00Cr20Ni25Mo4.5Cu, X1NiCrMoCu25-20-5 |

| Type | Seamless |

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS ASTM A240/ASME SA-240,ASTM A276,ASTM A182/ASME SA-182,ASTM A312/ASMES A312 ASTM B625/ASME B625,ASTM B673/ASME B673 |

| Available Grades | Stainless steel 301 / 302 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 321 / 32760 / 253MA / 254SMo / 410 / 420 / 430 / Custom465 / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65. Nitronic 30 / Nitronic 32 / Nitronic 33 / Nitronic 40 / Nitronic 50 / Nitronic 60 etc. |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 / Inconel 713C / Inconel 713LC | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Out diameter | Seamless Pipe 6MM - 1174MM or customized |

| Thickness | Seamless Pipe 1mm - 80mm or customized |

| Max Length | Seamless Pipe 12000mm or customized |

| Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

| Packing | waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |

Austenitic stainless steel grade 904L is designed to achieve moderate to high corrosion resistance. This is due to the high amount of molybdenum, chromium and nickel content. The resistance properties of grade 904L stainless steel pipes include good resistance to stress corrosion cracking, and pitting and crevice corrosion, as well as inter granular corrosion. The “L” in 904L stands for low carbon, i.e., only 0.03 percent or less. Grade 904L is also non-magnetic in all conditions, and has excellent machinability and weldability. Moreover, the austenitic structure gives it excellent toughness, even at cryogenic temperatures.

904L STAINLESS STEEL PIPE PROPERTIES

The following sections describe the properties of 904L stainless grade pipes supplied by Arch City Steel & Alloy:

Corrosion Resistance:

-

Excellent resistance to warm seawater and chloride attack. The high resistance against stress corrosion cracking is due to the presence of high amounts of nickel in its composition.

-

The addition of copper to grade 904L develops resistance to reducing agents including sulfuric acid in both aggressive and mild conditions.

- Less resistant to nitric acid than grades 304L and 310L, which are free of molybdenum.

-

Should to be solution treated after cold working, for achieving maximum resistance to stress corrosion cracking in adverse environments.

Heat Resistance:

-

Grade 904L stainless steel pipes offer good oxidation resistance.

-

Its structural stability diminishes at high temperatures, especially above 400°C.

Heat Treatment:

-

Grade 904L stainless steel pipes can be heat-treated at 1090 to 1175°C, following by rapid cooling.

- Thermal treatment is suitable for hardening these grades.

Weldability:

-

Welding can be performed using all conventional methods.

-

Grade 904L pipes do not require pre-heating and post-weld heat treatments.

-

These pipes can be subjected to hot cracking in constrained weldments.

-

Electrodes and rods of 904L stainless steel grade are used for welding steel pipes and other products of grade 904L.

Machinability:

-

Grade 904L steel pipes can be machined using any standard method.

-

This grade can be bent to a small radius in cold environments.

-

Subsequent annealing is not required mostly. However, annealing is recommended when the fabrication is executed under severe stress corrosion cracking environments.

Applications:

Due to the different kinds of elements, 904L is designed for harsh industrial environments. Typical applications are shown as below:

-

Wiring in electrostatic precipitators

-

Oil refinery components

-

Gas scrubbing plants

-

Pulp and paper processing industry

-

Seawater cooling equipment

-

Chemical processing industry

-

Acetic, phosphoric, and sulfuric acid processing plants

CHEMICAL PROPERTIES:

| Typical Chemical Composition % (max values, unless noted) | ||||||||||

| Grade | Cr | Ni | C | Si | Mn | P | S | Mo | Cu | Fe |

| 904L | min: 19 max: 23 |

min: 23 max: 28 |

0.02 Max | 1.0 max | 2.0 max | 0.045 max | 0.035 max | min: 4 max: 5 |

min: 1 max: 2 |

balance |

MECHANICAL PROPERTIES:

| Typical Room Temperature Mechanical Properties | |||||

| Grade |

Tensile Strength KSI (min.) |

Yield Strength 0.2% Offset KSI (min.) | Elongation % in 2ʺ(50.8 mm) | Hardness (Brinell) MAX |

Hardness (Rockwell B) MAX |

| 904L | 71 | 31 | 35 | 70-90 | 150 |

![]()

![]()

![]()

![]()