-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

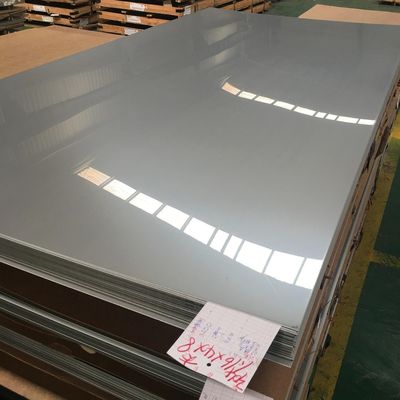

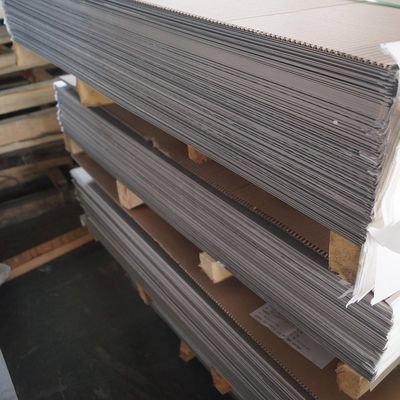

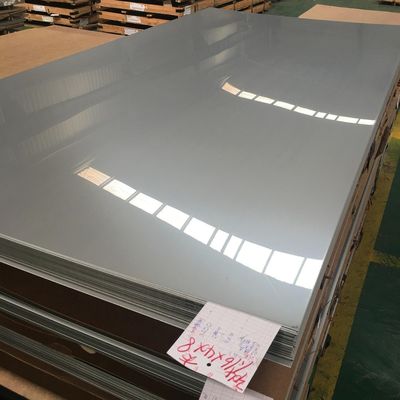

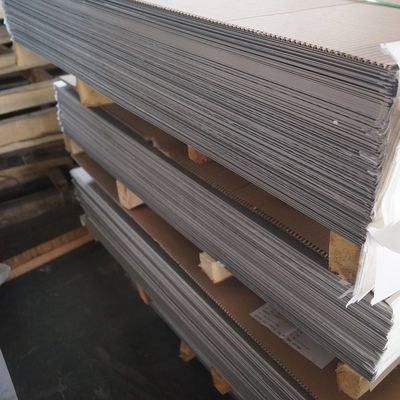

EN 10204-3.1 Certificate Inconel 600 Nickel Alloy Plate & Sheet Thickness 0.4 - 30.0mm Hot Rolled Cold Rolled

| Products | Nickel Alloy Sheet & Plate | Grade | Inconel 600 |

|---|---|---|---|

| Thickness | 0.5 - 30.0mm | Standard Size | 1000*2000mm 1219*2438mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 NO.4 NO.8 |

| Highlight | Hot Rolled Nickel Alloy Plate,Inconel 600 Nickel Alloy Plate |

||

EN 10204-3.1 Certificate Inconel 600 Nickel Alloy Plate & Sheet Thickness 0.4 - 30.0mm Hot Rolled Cold Rolled

| Products Name | Inconel 600 Nickel Alloy Sheet Plate |

| Thickness | Cold rolled: 0.5 - 3.0mm Hot rolled 4.0 - 30.0mm |

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Other Grade | Hastelloy C22 C4 X C276 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Inconel Alloy 600 Composition

Alloy 600 Properties

Alloy 600 properties is that it has a Chemical Composition of Cu 0.5% max, C 0.15% max, Mn 1% max, S 0.015% max, Fe 6% - 10%, Ni 72% min, Cr 14% - 17% and Si 0.5% max. The Density of Inconel 600 is 0.306 lb/in³ (8.47 g/cc). Inconel 600 Ultimate Tensile Strength is 95000 psi (655 MPa). The Ultimate Tensile Strength of Alloy 600 at Elevated Temperature is 79800 psi (550 MPa). The Yield Tensile Strength of Alloy 600 is 45000 psi (310 MPa). The Yield Tensile Strength of Inconel 600 at Elevated Temperature 26100 psi (180 MPa).

UNS Number N06600

Other common names: Alloy 600

In what form is Inconel 600 Available at Steel Tubes India?

- Sheet

- Plate

- Bar

- Pipe & Tube (welded & seamless)

- Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

- Wire

What are the characteristics of Inconel 600?

- Resistant to a wide range of corrosive media.

- Virtually immune to chlorine ion stress corrosion cracking

- Non-magnetic

- Excellent mechanical properties

- High strength and good weldability under a wide range of temperatures

Chemical Composition, %

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

|---|---|---|---|---|---|---|---|

| 72.0 min | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 max | .50 max | .50 max |

In what applications is Inconel 600 used?

- Chemical industry

- Aerospace

- Heat treating industry

- Pulp and paper industry

- Food processing

- Nuclear Engineering

- Gas turbine components

Fabrication with Alloy 600 UNS N06600

Alloy 600 can be both hot formed and cold formed using typical processes. Hot working should be performed between 1600° F and 2250° F avoiding any work between1200-1600° F because the ductility decreases in this temperature range. Welding Alloy 600 can be achieved via shielded metal-arc welding, TIG, and MIG.

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting | Wire |

|---|---|---|---|---|---|---|---|---|

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Mechanical Properties

Typical room temperature Tensile Properties of Annealed Material

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|---|

| Rod & Bar | Cold-Drawn | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Hot-Finished | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Pipe | Hot-Finished | 75-100 | 25-50 | 35*55 | - |

| Tube & Pipe | Cold-Drawn | 80-100 | 25-50 | 35-55 | 88 Max |

| Plate | Hot-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Sheet | Cold-Drawn | 80-100 | 30-45 | 35-55 | 88 Max |

Inconel 600 Temperature Range

Inconel 600 temperature range is such that it can be used from cryogenic temperatures to temperatures ranging between 1093 °C (2000 °F). Inconel 600 material is most commonly used in structural engineering because it is perfect for high temperatures above 1000 °F (540 °C). Inconel 600 is durable, stable, strong and corrosion resistant. Inconel 600 is also called a super alloy, because of its intense characteristics, such as performing under tremendous mechanical stress and temperatures and showing resistance against oxidation and creep. Inconel 600 (UNS N06600) is also used in heat treatment furnace components and fittings, heat exchangers, etc.

Inconel 600 Melting Point

Inconel 600 melting point lies between 2470 - 2580 °F (1354 - 1413 °C). The Thermal Conductivity of Inconel 600 is 103 BTU-in/hr-ft²-°F (14.9 W/m-K). The Liquidus of Inconel 600 is 2580 °F (1413 °C). Inconel 600 Solidus is 2470 °F (1354 °C). The Specific Heat Capacity of Inconel 600 is 0.106 BTU/lb-°F (0.444 J/g-°C). The Curie Temperature of Inconel 600 is -317 °F (-194 °C). Inconel 600 Elongation at Break is 45%. The Elongation at Break of Alloy 600 at Elevated Temperature is 42%. The Electrical Resistivity of Inconel 600 is 0.000103 ohm-cm. Inconel 600 Magnetic Permeability is 1.01.

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Inconel 600 Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Whats new:

- Alloy 600 Pipe supplier

- Alloy 600 Tube supplier

- Alloy 600 Tubing supplier

- Alloy 600 Plate supplier

- Alloy 600 Sheet supplier

- Alloy 600 Round Bar supplier

- Alloy 600 Pipe Fittings supplier

- Alloy 600 Forged Fittings supplier

- Alloy 600 Flanges supplier

- Alloy 600 Fasteners supplier

- Alloy 600 Nuts supplier

- Alloy 600 Bolts supplier

- Alloy 600 Wire supplier

- Inconel 600 Seamless Pipe supplier

- Inconel 600 Welded Pipe supplier

- Inconel 600 Seamless Tube supplier

- Inconel 600 Seamless Tubing supplier

- Inconel 600 Coil supplier

- Inconel 600 Strip supplier

- Inconel 600 Foil supplier

![]()

![]()

![]()

![]()