-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

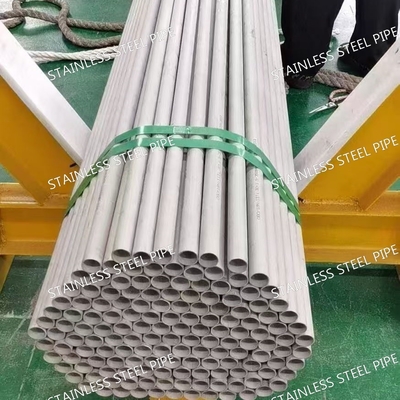

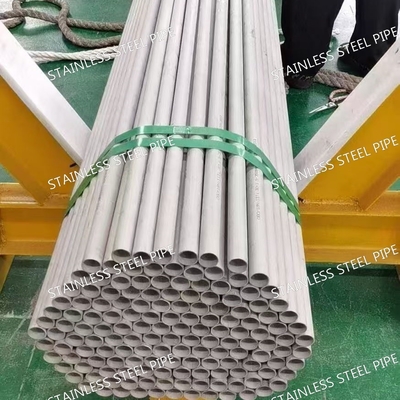

310S Stainless Steel Seamless Pipe DN80 SCH40S High Temperature Resistant

Contacte-me para amostras grátis e vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

x| Products | Stainless Steel Seamless Pipe | Grade | 310S |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m or custom cutting any length as request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Destacar | 310S stainless steel seamless pipe,DN80 SCH40S stainless pipe,high temperature resistant steel pipe |

||

High Temperature Resistant 310S Stainless Steel Tube / Stainless Steel Pipe Seamless DN80 SCH40S SS Pipe

Products Specification

| Products Name | 310S Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

310S stainless steel (UNS S31008) is an austenitic chromium-nickel alloy designed for extreme high-temperature applications. Its high chromium (24–26%) and nickel (19–22%) content ensures exceptional oxidation resistance, creep strength, and corrosion durability up to 1150°C continuously and 1200°C intermittently238. Below are key details structured for technical reference.

1. Chemical Composition

310S prioritizes oxidation resistance and high-temperature stability through balanced alloying:

Table: Chemical Composition (Weight %)5710

| Element | C | Cr | Ni | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| Min | - | 24.00 | 19.00 | - | - | - | - | 53.095 |

| Max | 0.08 | 26.00 | 22.00 | 2.00 | 1.00 | 0.045 | 0.030 | Balance |

2. Mechanical & Physical Properties

Optimized for high-temperature structural integrity:

Table: Mechanical Properties (Room Temperature)2510

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) |

|---|---|---|---|---|

| ≥515 | ≥205 | ≥40 | ≤187 | 7.98 |

Table: Physical Properties10

| Melting Point (°C) | Thermal Conductivity (W/m·K) | Coefficient of Expansion (10⁻⁶/K) |

|---|---|---|

| 1397–1453 | 16.3–21.5 (100–500°C) | 14.4–17.5 (100–500°C) |

3. Standards & Equivalent Grades

Widely standardized globally for seamless/welded tubes:

Table: International Equivalents356

| Region | Standard | UNS | EN | JIS | GB (China) | GOST (Russia) |

|---|---|---|---|---|---|---|

| USA | ASTM A213/A312 | S31008 | 1.4845 | SUS 310S | 06Cr25Ni20 | 20Ch23N18 |

| Europe | EN 10216-5 | – | X8CrNi25-21 | – | – | – |

Key Standards:

-

Seamless Tubes: ASTM A213, ASME SA213, EN 10216-559

-

Welded Tubes: ASTM A312, ASME SA3129

-

Fittings: ASTM A403 (WP310S for forged parts)6

4. Applications

310S tubes excel in thermally aggressive environments:

-

Energy & Petrochemical: Boiler tubes, reheaters, refinery heaters, fluidized bed combustors89.

-

Industrial Furnaces: Radiant tubes, kiln linings, burner nozzles, annealing covers39.

-

Waste & Processing: Incinerators, salt pots, food processing equipment89.

-

Mechanical Components: Heat exchanger tubing, thermocouple sleeves, high-pressure piping57.

5. Packaging & Specifications

-

Dimensions:

-

OD: 6–914 mm (seamless); up to 24" NB (welded)19

-

Thickness: 0.3–50 mm (SCH 5 to XXS)9

-

Length: 3,500–7,500 mm (6,000 mm standard)1

-

-

Packaging: Plastic caps, woven bags, wooden crates1.

-

Tolerance:

-

Outer Diameter: ±0.5% (D2 grade)7

-

Straightness: ≤1.5 mm1.

-

6. Special Processing

-

Surface Finish: Annealed/pickled, polished, bright-annealed (BA)59.

-

Ends: Plain, beveled, threaded5.

-

Heat Treatment: Solution-annealed at ≥1040°C, water-quenched6.