-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

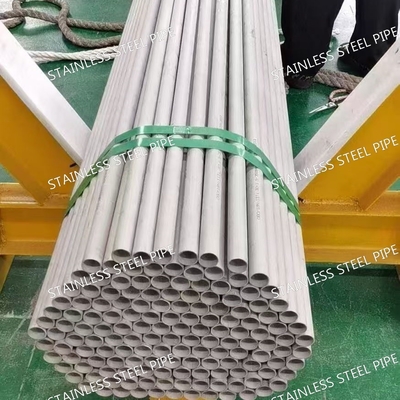

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

310S Stainless Steel Seamless Pipe DN80 SCH40S High Temperature Resistant

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Products | Stainless Steel Seamless Pipe | Grade | 310S |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m or custom cutting any length as request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Mettre en évidence | 310S stainless steel seamless pipe,DN80 SCH40S stainless pipe,high temperature resistant steel pipe |

||

High Temperature Resistant 310S Stainless Steel Tube / Stainless Steel Pipe Seamless DN80 SCH40S SS Pipe

Products Specification

| Products Name | 310S Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

310S stainless steel (UNS S31008) is an austenitic chromium-nickel alloy designed for extreme high-temperature applications. Its high chromium (24–26%) and nickel (19–22%) content ensures exceptional oxidation resistance, creep strength, and corrosion durability up to 1150°C continuously and 1200°C intermittently238. Below are key details structured for technical reference.

1. Chemical Composition

310S prioritizes oxidation resistance and high-temperature stability through balanced alloying:

Table: Chemical Composition (Weight %)5710

| Element | C | Cr | Ni | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| Min | - | 24.00 | 19.00 | - | - | - | - | 53.095 |

| Max | 0.08 | 26.00 | 22.00 | 2.00 | 1.00 | 0.045 | 0.030 | Balance |

2. Mechanical & Physical Properties

Optimized for high-temperature structural integrity:

Table: Mechanical Properties (Room Temperature)2510

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) |

|---|---|---|---|---|

| ≥515 | ≥205 | ≥40 | ≤187 | 7.98 |

Table: Physical Properties10

| Melting Point (°C) | Thermal Conductivity (W/m·K) | Coefficient of Expansion (10⁻⁶/K) |

|---|---|---|

| 1397–1453 | 16.3–21.5 (100–500°C) | 14.4–17.5 (100–500°C) |

3. Standards & Equivalent Grades

Widely standardized globally for seamless/welded tubes:

Table: International Equivalents356

| Region | Standard | UNS | EN | JIS | GB (China) | GOST (Russia) |

|---|---|---|---|---|---|---|

| USA | ASTM A213/A312 | S31008 | 1.4845 | SUS 310S | 06Cr25Ni20 | 20Ch23N18 |

| Europe | EN 10216-5 | – | X8CrNi25-21 | – | – | – |

Key Standards:

-

Seamless Tubes: ASTM A213, ASME SA213, EN 10216-559

-

Welded Tubes: ASTM A312, ASME SA3129

-

Fittings: ASTM A403 (WP310S for forged parts)6

4. Applications

310S tubes excel in thermally aggressive environments:

-

Energy & Petrochemical: Boiler tubes, reheaters, refinery heaters, fluidized bed combustors89.

-

Industrial Furnaces: Radiant tubes, kiln linings, burner nozzles, annealing covers39.

-

Waste & Processing: Incinerators, salt pots, food processing equipment89.

-

Mechanical Components: Heat exchanger tubing, thermocouple sleeves, high-pressure piping57.

5. Packaging & Specifications

-

Dimensions:

-

OD: 6–914 mm (seamless); up to 24" NB (welded)19

-

Thickness: 0.3–50 mm (SCH 5 to XXS)9

-

Length: 3,500–7,500 mm (6,000 mm standard)1

-

-

Packaging: Plastic caps, woven bags, wooden crates1.

-

Tolerance:

-

Outer Diameter: ±0.5% (D2 grade)7

-

Straightness: ≤1.5 mm1.

-

6. Special Processing

-

Surface Finish: Annealed/pickled, polished, bright-annealed (BA)59.

-

Ends: Plain, beveled, threaded5.

-

Heat Treatment: Solution-annealed at ≥1040°C, water-quenched6.