All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

TP347H Stainless Steel Seamless Pipe DN10-DN400 ASTM EN

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Seamless Pipe | Grade | 347 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | TP347H stainless steel pipe,ASTM stainless steel seamless pipe,DN10-DN400 stainless steel pipe |

||

Product Description

Alloy 347H Stainless Steel Tubing / ASTM A312 Austenitic Stainless Pipes TP347H for Industrial

Products Specification

| Products Name | 347 Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

TP347H Stainless Steel Pipe: High-Temperature Performance for Critical Industrial Applications

TP347H stainless steel pipe is a premium-grade austenitic stainless steel designed for extreme environments requiring high-temperature strength and corrosion resistance. The "TP" designation indicates its use as Tube/Pipe, while the "H" suffix denotes higher carbon content (0.04–0.10%) for enhanced creep resistance at elevated temperatures. Stabilized with niobium (Nb), it prevents carbide precipitation at grain boundaries, making it ideal for welded components in corrosive and high-heat settings

Chemical Composition

| Element | Content Range (%) | Role in Performance |

|---|---|---|

| Chromium (Cr) | 17.0–19.0 | Forms a protective oxide layer, enhancing resistance to oxidation and corrosion. |

| Nickel (Ni) | 9.0–13.0 | Stabilizes the austenitic structure, improving ductility and toughness. |

| Niobium (Nb) | ≥5×Carbon (C) | Prevents sensitization (carbide formation) during welding or high-temperature exposure. |

| Carbon (C) | 0.04–0.10 | Boosts high-temperature strength and creep resistance. |

| Manganese (Mn) | ≤2.0 | Aids in deoxidation and improves hot workability. |

| Silicon (Si) | ≤1.0 | Enhances oxidation resistance and acts as a deoxidizer. |

| Phosphorus (P) | ≤0.045 | Controlled to minimize brittleness. |

| Sulfur (S) | ≤0.030 | Reduces hot cracking during welding when kept low. |

Mechanical Properties

| Property | Minimum Value | Testing Condition |

|---|---|---|

| Tensile Strength | 515 MPa (75,000 psi) | Room temperature |

| Yield Strength (0.2% offset) | 205 MPa (30,000 psi) | Room temperature |

| Elongation (in 50 mm) | 35–40% | After annealing |

| Hardness (HRB) | 95 (max) | Room temperature |

Standards & Specifications

TP347H pipes comply with rigorous international and industry standards:

| Standard | Application Scope |

|---|---|

| ASTM A213/ASME SA213 | Boiler, superheater, and heat exchanger tubes for high-pressure steam systems |

| ASTM A312/ASME SA312 | Seamless and welded pipes for corrosive environments |

| GB/T 14976 | Chinese standard for fluid transport and boiler applications |

| EN 10216-2 | European standard for pressure tubes in high-temperature services. |

Typical Applications

TP347H pipes excel in industries demanding reliability under extreme conditions:

| Industry | Applications |

|---|---|

| Power Generation | Boiler tubes, superheaters, reheaters, and high-pressure steam pipelines in coal-fired and gas-fired power plants |

| Petrochemical | Refinery equipment, catalytic crackers, and process piping handling corrosive fluids like hydrogen sulfide |

| Chemical Processing | Reactors, heat exchangers, and pipelines for acids, alkalis, and organic solvents. |

| Aerospace | Exhaust systems and structural components in jet engines and aerospace propulsion systems |

Key Advantages

-

Exceptional High-Temperature Stability:

Maintains structural integrity up to 816°C (1500°F) and resists creep deformation in prolonged high-heat applications -

Corrosion Resistance:

Niobium stabilization prevents intergranular corrosion, even after welding, making it suitable for aggressive chemical environments -

Superior Weldability:

Compatible with TIG, MIG, and plasma welding methods without significant loss of mechanical properties -

Formability:

Readily cold-worked (e.g., bending, rolling) and hot-formed (e.g., forging) with proper process control -

Cost-Effective Performance:

Outperforms 321H in extreme temperatures (above 537°C) while offering comparable corrosion resistance

Packaging & Handling

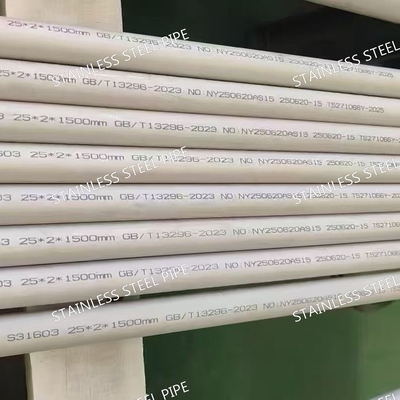

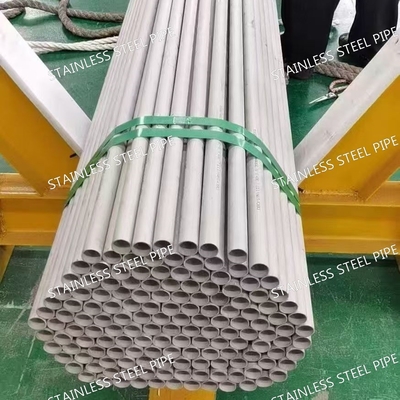

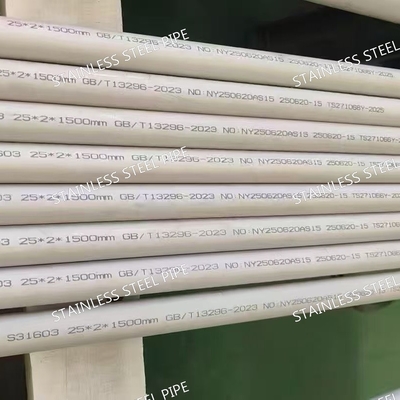

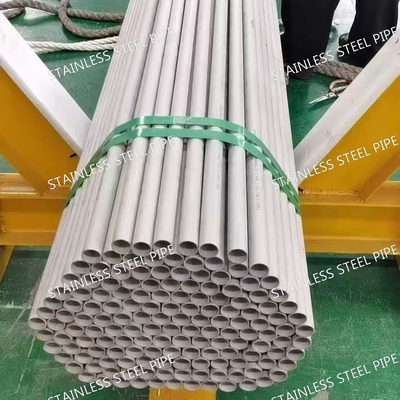

TP347H pipes are packaged to ensure damage-free transport:

- Inner Protection: Ends capped with plastic to prevent debris ingress.

- Weather Resistance: Wrapped in plastic film or woven cloth to guard against moisture and abrasion

- Secure Bundling: Bundled with steel straps or polypropylene bands for stability during shipping.

- Custom Options: Wooden crates or pallets available for sensitive or large-diameter pipes

Conclusion

TP347H stainless steel pipe combines niobium stabilization and high-carbon content to deliver unmatched performance in high-temperature, corrosive environments. Its compliance with global standards, robust mechanical properties, and versatility make it the material of choice for critical infrastructure in power, petrochemical, and aerospace industries. Whether in boiler tubes for a Thai power plant or refinery reactors, TP347H ensures longevity and reliability where failure is not an option.

Recommended Products